Abrasive product and method of making and using the same

a technology of abrasive products and abrasives, which is applied in the direction of flexible wheel, metal-working apparatus, manufacturing tools, etc., can solve the problems of preventing the proper cure of precursor polymer subunits, patterned abrasive coatings, and abrasive granules having a specified pattern on the backing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0200] Pre-mix #1: 60.8 parts CN973J75, 36.4 parts SR339 and 2.8 parts TPO-L were combined using a mixer, available under the trade designation DISPERSATOR from Premier Mill Corp., Reading, Pa., at room temperature until air bubbles had dissipated.

[0201] Slurry #1: 3.4 parts of pre-expanded F80 was then added to 96.6 parts of Pre-mix #1 and formed into homogeneous slurry #1 using the DISPERSATOR mixer. F80 microspheres were pre-expanded at 160.degree. C. for 60 minutes before use.

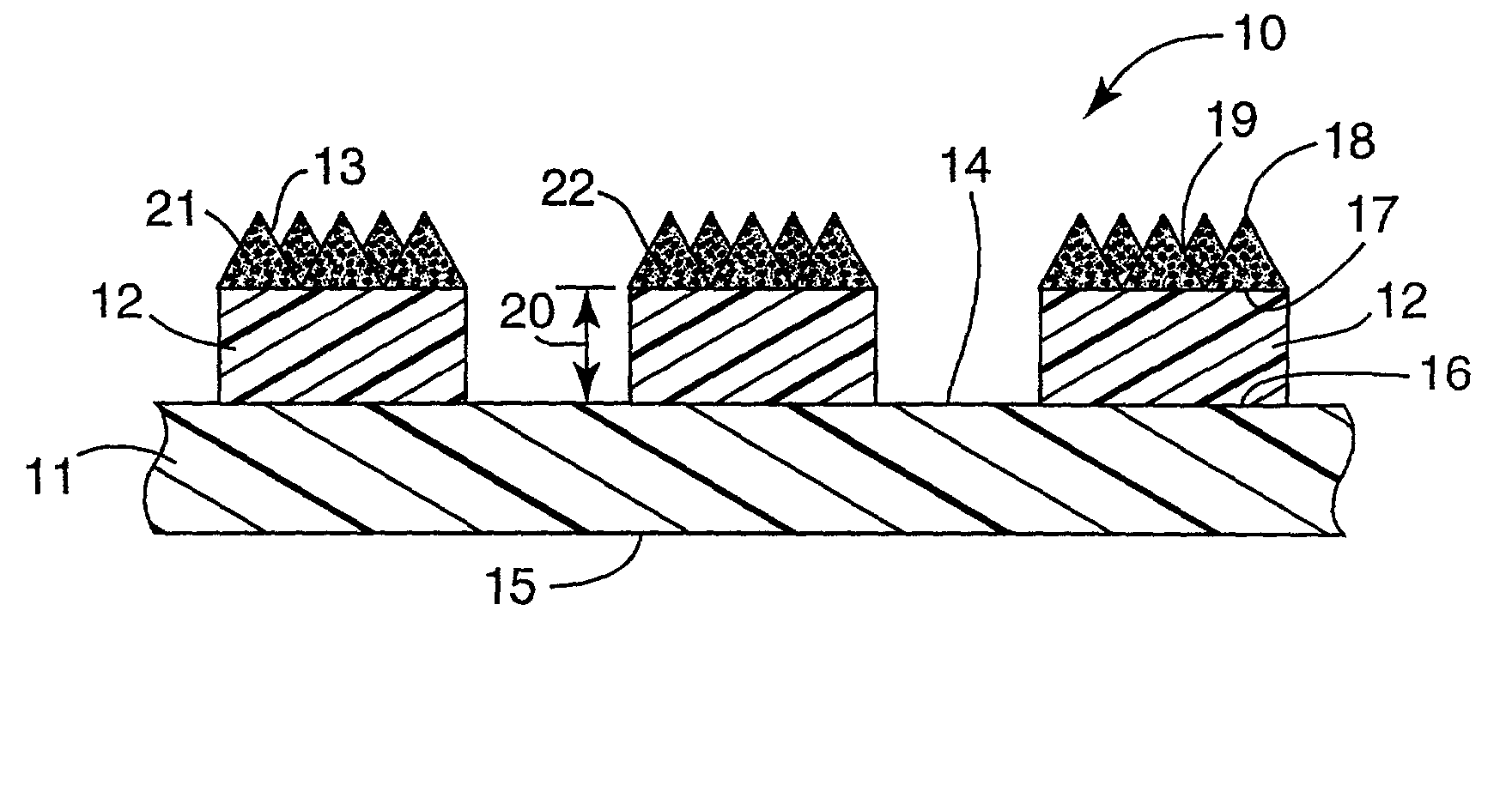

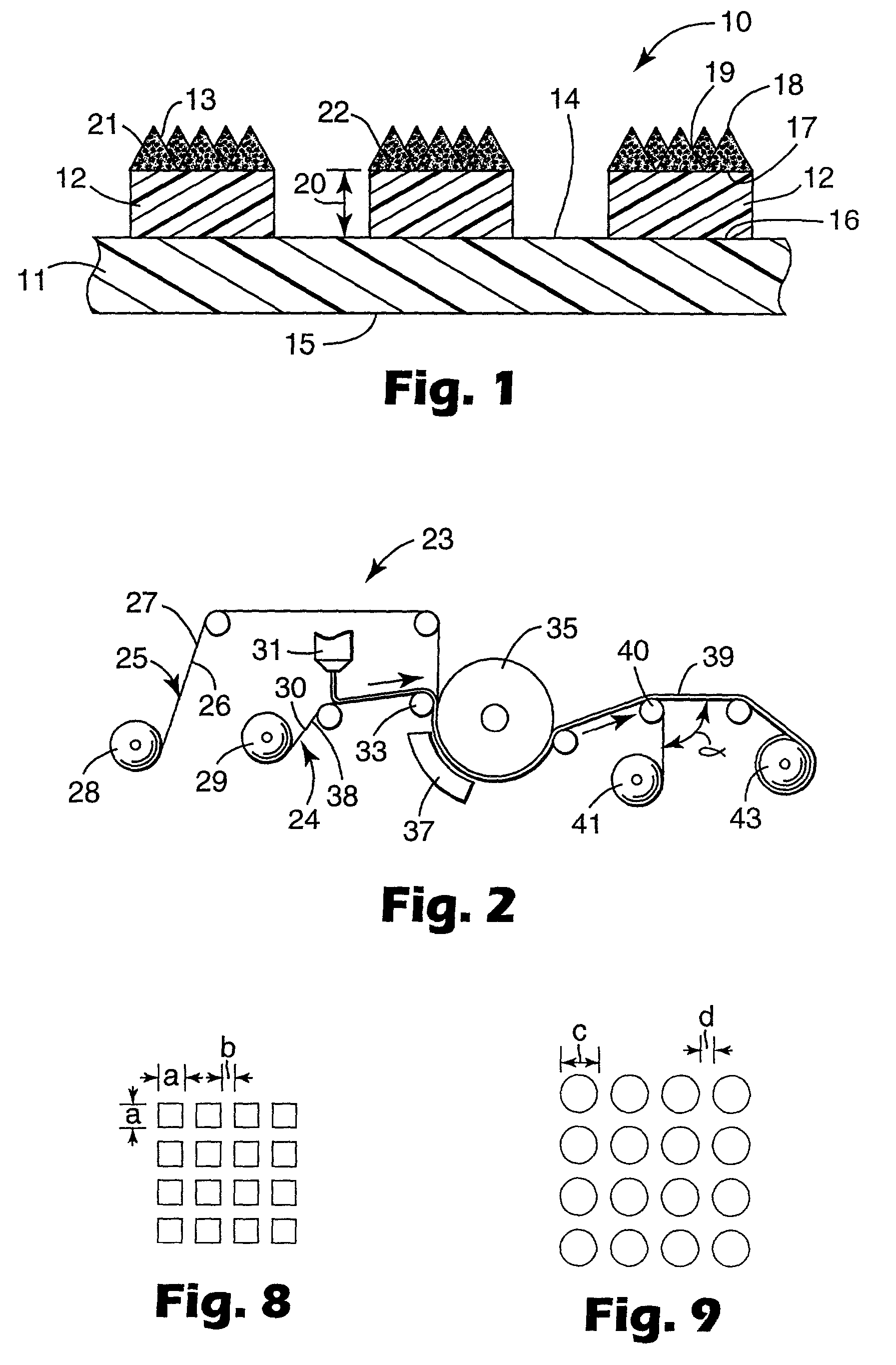

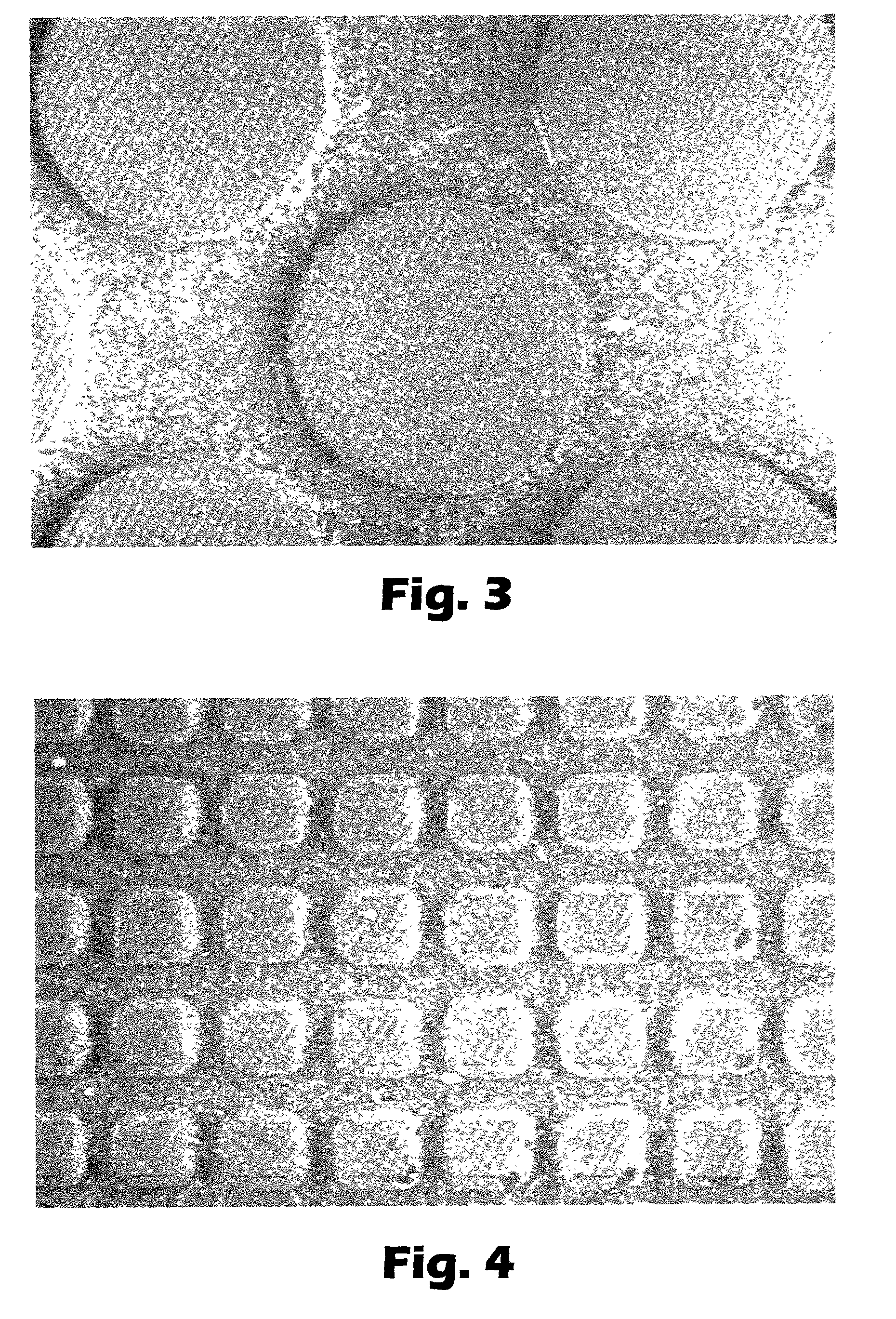

[0202] Slurry #1 was then applied, via hand spread, to a microreplicated tooling having square posts, 1.3 mm.times.1.3 mm.times.0.356 mm deep, with a 22% bearing area, as described in Table 3. The slurry filled tooling was then laminated face down to the smooth side of corona treated backing available from Minnesota Mining and Manufacturing Company (3M) under the trade designation 3M HOOK-IT II.TM. backing by passing through a set of rubber nip rolls at 26 cm / min. and a nip pressure of 275 kPa (40 psi). The...

example 2

[0206] A 3-dimensional abrasive coating on top of 3-dimensional foam structure was prepared as outlined in Example 1, wherein slurry #1 was applied to a microreplicated tooling having the same square posts but with a 32% bearing area, as described in Table 3.

example 3

[0207] A 3-dimensional abrasive coating on top of 3-dimensional foam structure was prepared as outlined in Example 1, wherein slurry #1 was applied to a microreplicated tooling having the same square posts but with a 42% bearing area, as described in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com