Connecting node

a node and connection technology, applied in the direction of rod connection, coupling, building scaffold, etc., can solve the problem of limiting the utilization of connectors in a single structure, and achieve the effect of optimum structural operation, fast and safe manner, and tight and safe connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

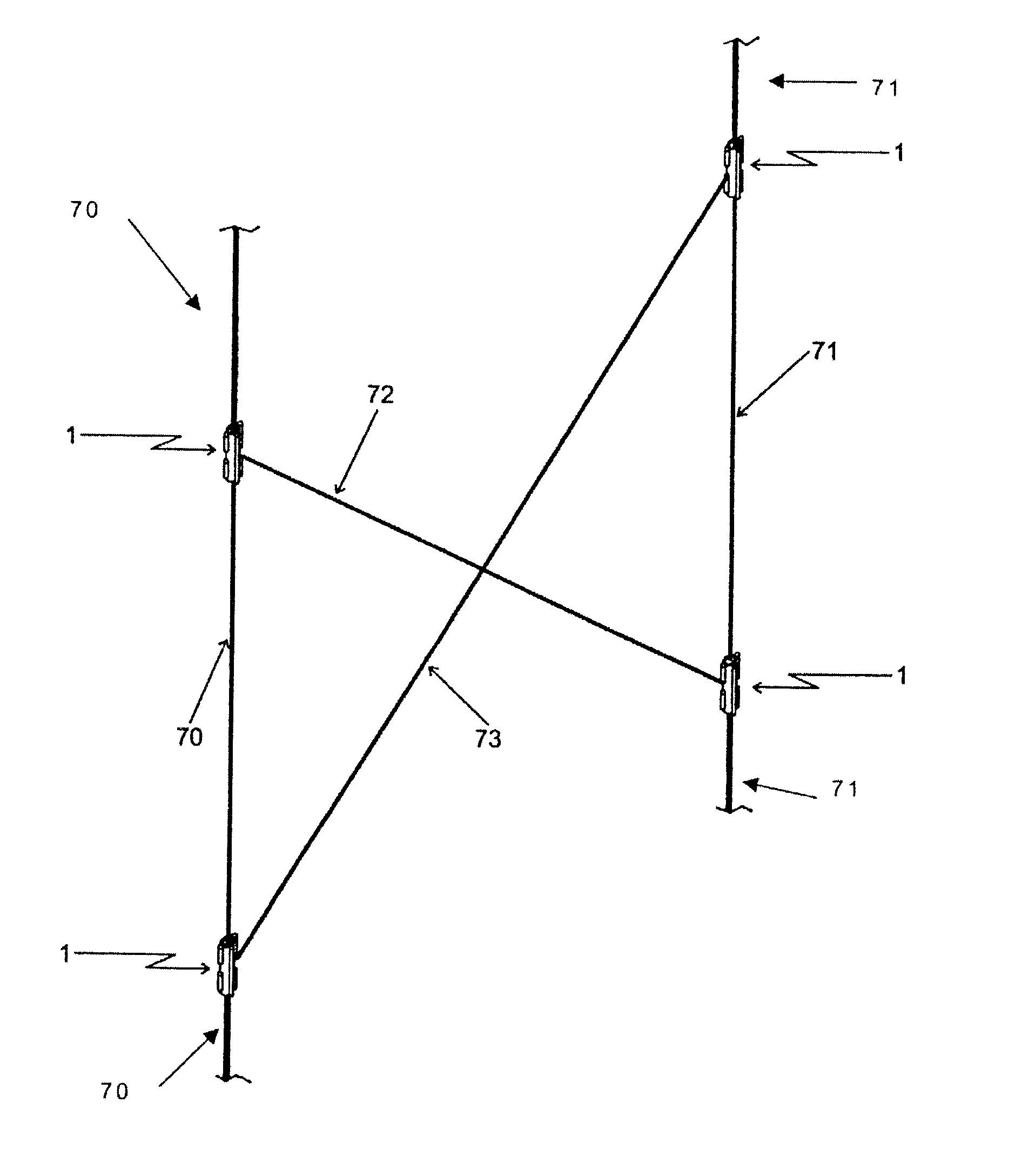

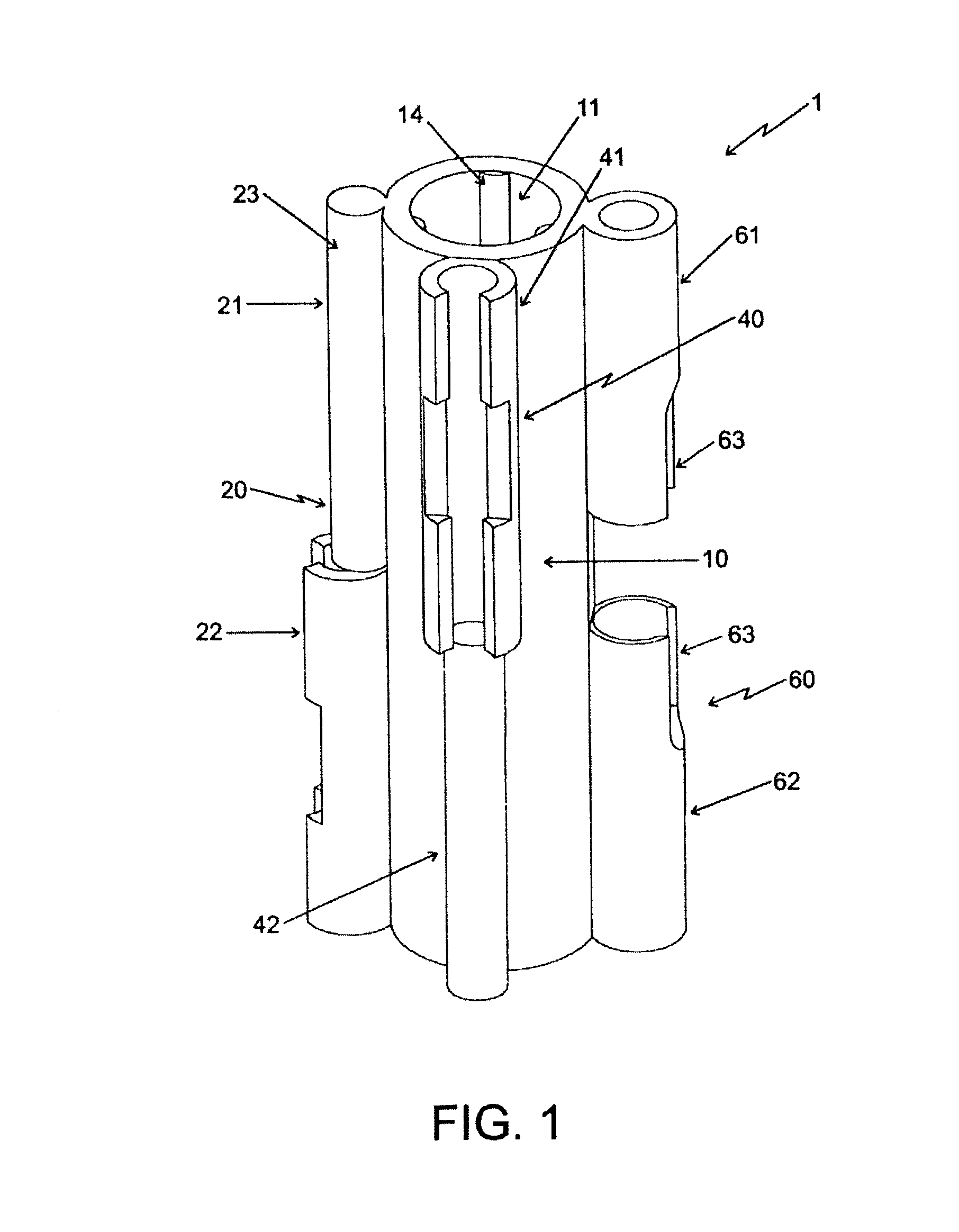

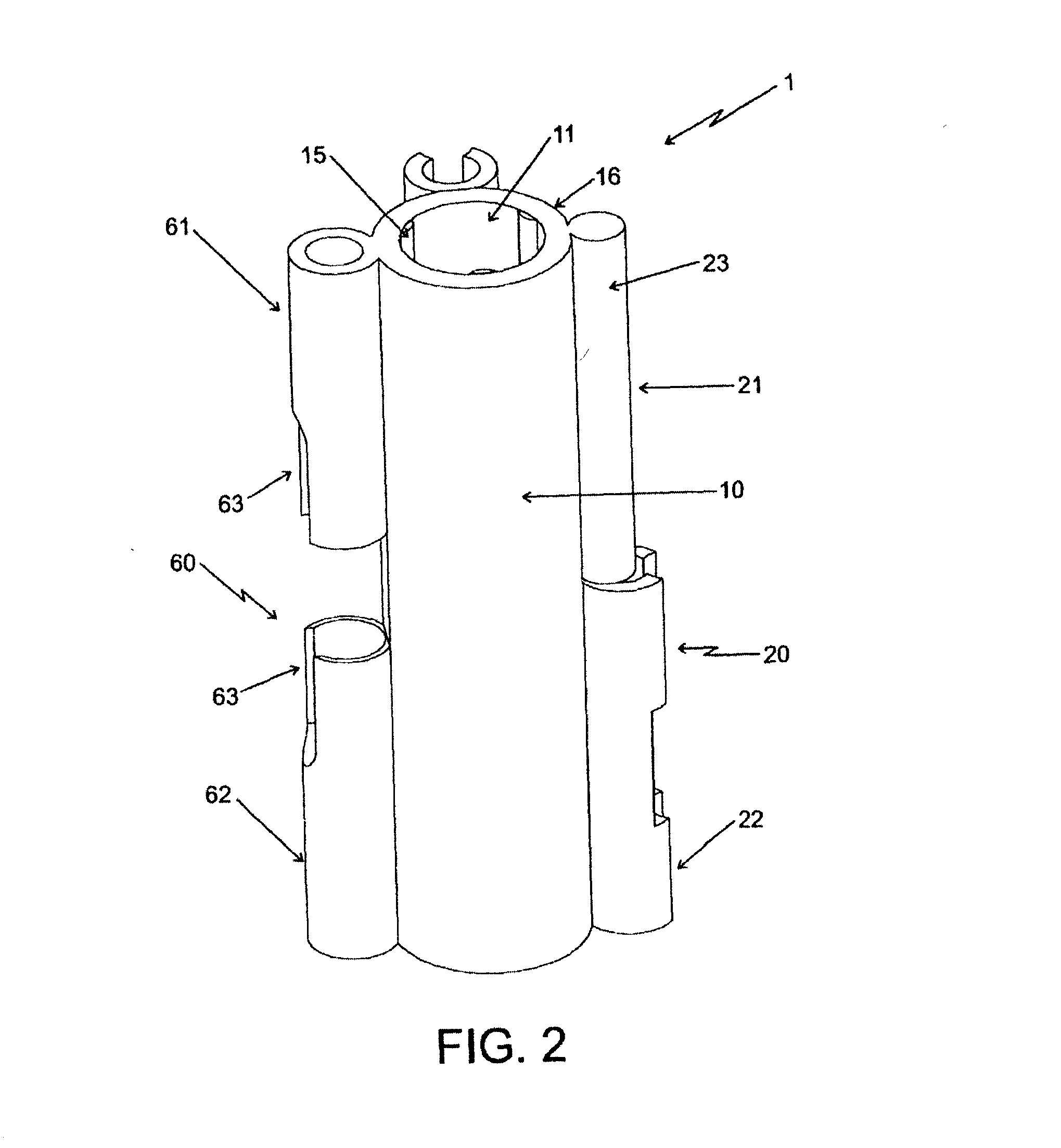

[0020] Referring to FIGS. 1 to 8, the connecting node 1 is illustrated which is formed from a cylindrical main body 10, which houses inside an upper recess 11 and a lower recess 12, separated by an intermediate wall 13, forming part of the same cylindrical main body 10. In such upper 11 and lower 12 recesses end edges extend from the cylindrical main body 10 ends towards the opposite end, being limited by intermediate wall 13, such that said upper 11 and lower 12 recesses present a depth of approximately half the total length of the main body 10 of connecting node 1, leaving such depth limited only by intermediate wall 13.

[0021] The diameter of the upper 11 and lower 12 recesses is determined such that wall thickness forming between these two recesses 11, 12 and cylindrical main body 10 is sufficiently resistant to uphold exertions to which the connecting node 1 is submitted, once structural elements 70, 71 integrating erecting structure are billeted inside such upper 11 and lower 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com