Ceramic heater

a ceramic heater and heater body technology, applied in the field of ceramic heaters, can solve the problems of uniform cure of resin and thermal shock to the wafer, and achieve the effect of improving uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

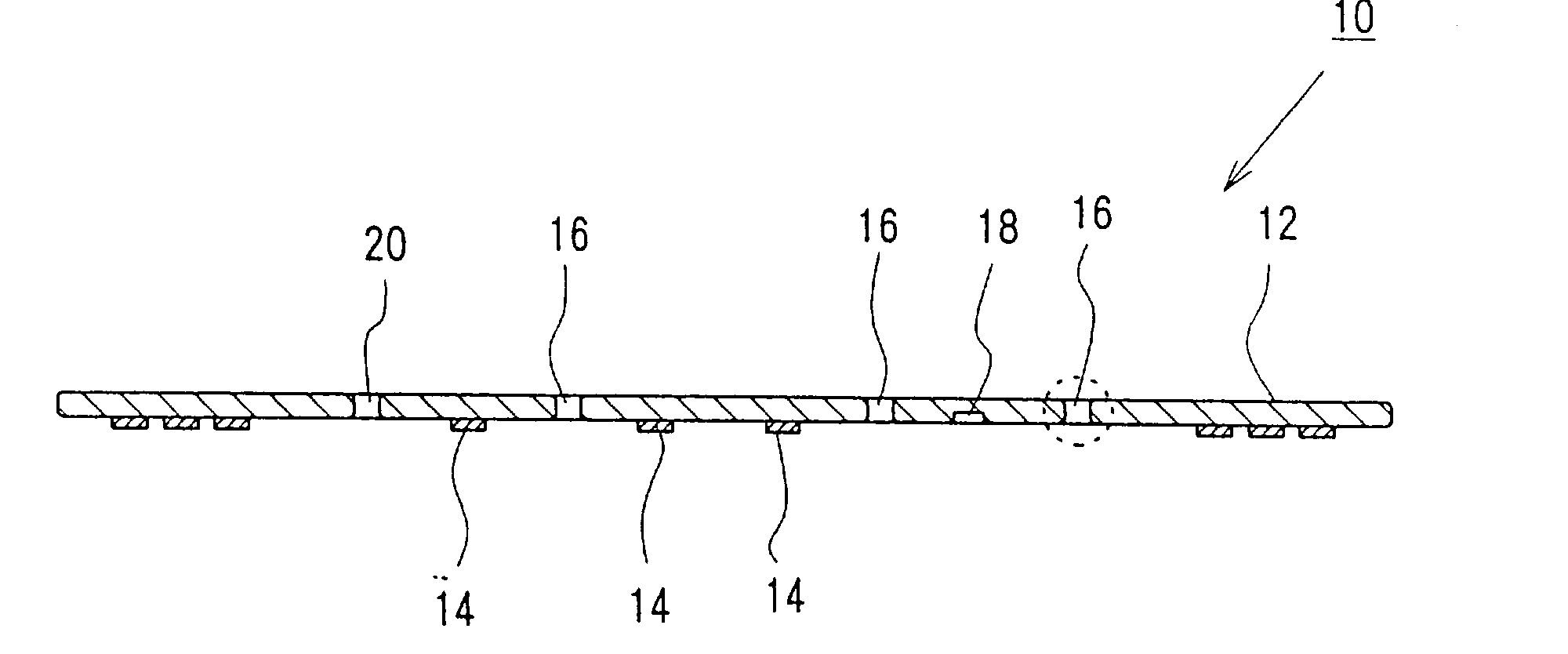

Manufacture of a Ceramic Heater Having a Heat Generation Body on the Surface of a Ceramic Substrate

[0086] (1) A composition comprising 100 parts by weight of an aluminum nitride powder with an average grain size of 0.6 .mu.m, 4 parts by weight of yttria (average grainze: 0.4 .mu.m), 12 parts by weight of an acrylic binder and alcohol was spray dried to prepare a granular powder.

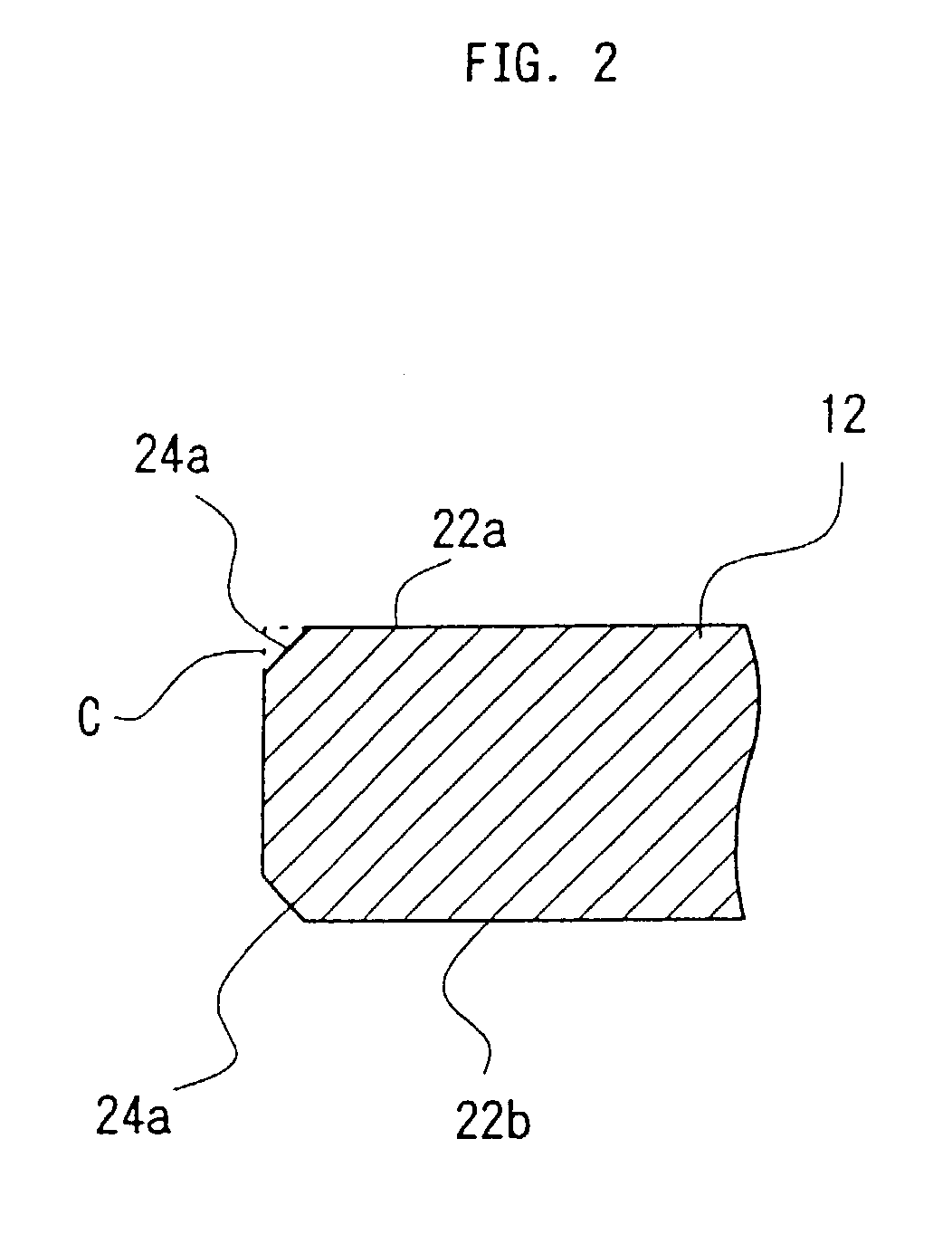

[0087] (2) Then, the granular powder was placed in a molding die, and molded into a flat plate to obtain a green molding product (green). Drilling was applied to the green molding product by using drills having a diameter of 10 mm and 0.1 mm to form portions as through holes (25 mm diameter) at 18 positions for inserting support pins (lifter pins) of a semiconductor wafer and portions as recesses for burying thermocouples (diameter: 1.1 mm, depth: 2 mm) at 5 positions (A, B, C, F and G in FIG. 13).

[0088] (3) The green molding product after the drilling was hot pressed at 1800.degree. C., under a pressure of 2...

example 2

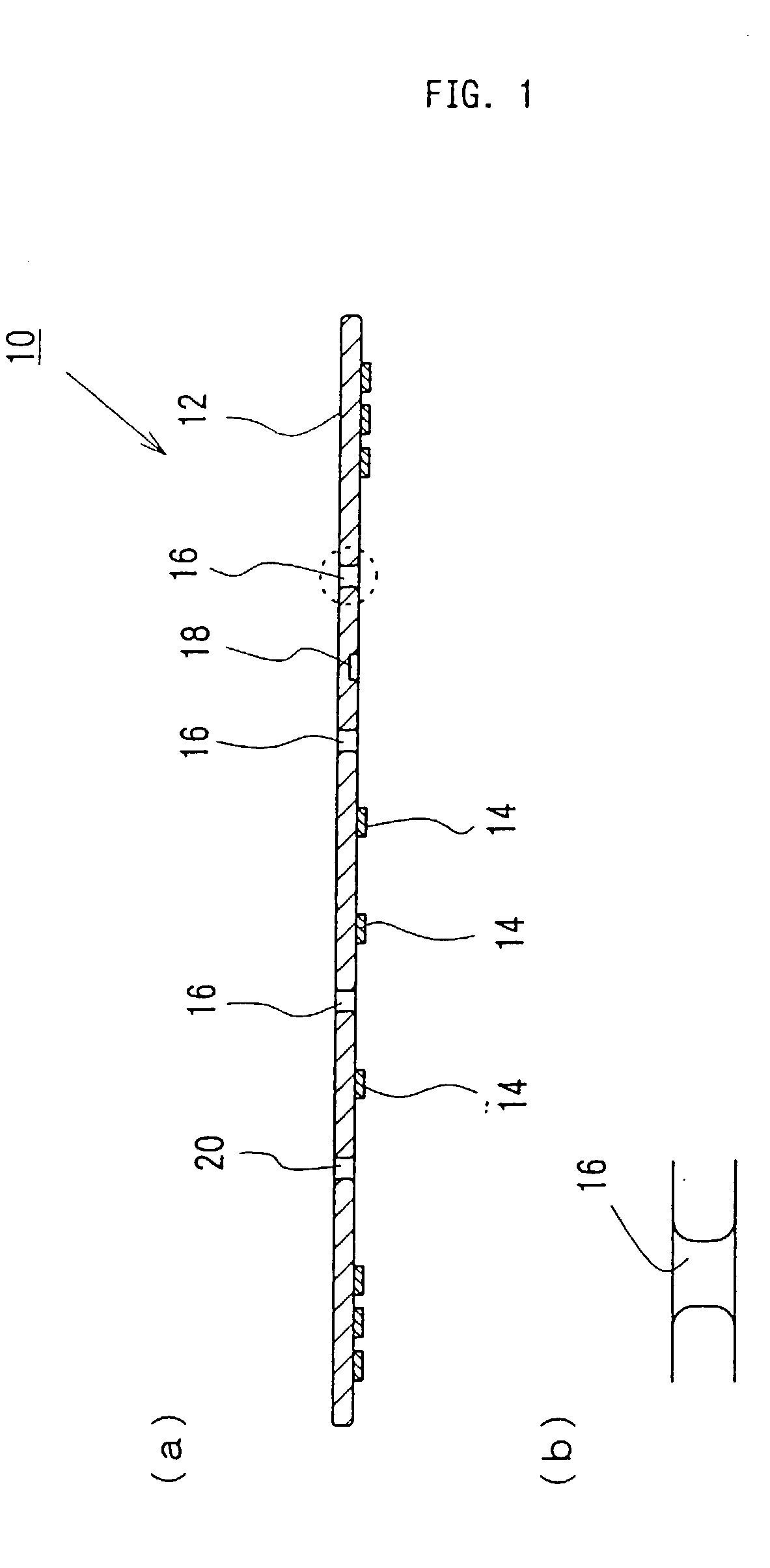

Manufacture of a Ceramic Heater Having a Heat Generation Body and an Electrostatic Electrode for Electrostatic Chuck

[0101] (1) Paste comprising, in admixture, 100 parts by weight of aluminum nitride (average grainsize: 1.1 .mu.m), 4 parts by weight yttria (average grain size: 0.4 .mu.m), 11.5 parts by weight of an acrylic binder, 0.5 parts by weight of a dispersant and 53% by weight of an alcohol comprising 1-butanol and ethanol was used and molded by a doctor blade method to obtain a green sheet of 0.47 mm thickness.

[0102] (2) Then, after drying the green sheet at 80.degree. C. for five hours, portions as through holes 15 for insertion of semiconductor wafer support pins of 1.8 mm, 3.0 mm and 5.0 mm in diameter and portions as through holes 18 for connection with external terminals were formed by punching.

[0103] (3) 100 parts by weight of tungsten carbide particles of 1 .mu.m average grain size, 3.0 parts by weight of an acrylic binder, 3.5 parts by weight of .alpha.-terpiol solven...

example 3

Manufacture of a Wafer Prober Having a Heater Function

[0112] A waver prober having the heater function was manufactured and it is explained with reference to FIG. 11 and FIG. 12.

[0113] (1) A composition comprising, in admixture, 100 parts by weight of aluminum nitride powder (average grain size: 1.1 .mu.m), 4 parts by weight yttria (average grain size; 0.4 .mu.m), 11.5 parts by weight of an acrylic binder, 0.5 parts by weight of a dispersant and 53% by weight of an alcohol comprising 1-butanol and ethanol described above was formed by a doctor blade to obtain a green sheet 54 of 0.47 mm thickness (refer to FIG. 11(a)).

[0114] (2) After drying the green sheet 54 at 80.degree. C. for five hours, holes for through holes for connecting the heat generation body and the external terminal pins were formed by punching (refer to FIG. 11(a)).

[0115] (3) 100 parts by weight of tungsten carbide particles of 1 .mu.m average grain size, 3.0 parts by weight of an acrylic binder, 3.5 parts by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com