Urethane elastomers with improved color stability

a technology of urethane elastomers and color stability, which is applied in the field of golf balls, can solve the problems of lack of durability required by recreational golfers, easy damage, and balata-covered balls, and achieve the effects of reducing or preventing the rapid degradation of color, and uv absorption and/or blocking qualities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0162] Comparison of Conventional Polyurethane Golf Ball Covers Versus a Polyurethane Cover Produced According to the Invention.

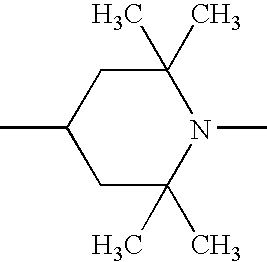

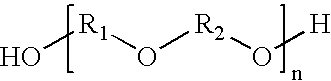

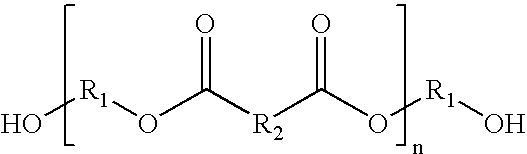

[0163] Two identically-constructed golf balls were prepared, each including a liquid-filled center, a wound layer, and a polyurethane cover. The first golf ball (Formulation I"), prepared according to the invention, has a cover layer formed of the polyurethane composition of the present invention including a reaction product of 4,4'-diphenylmethane diisocyanate ("MDI"), polytetramethylene ether glycol ("PTMEG"), a mixture of 3,5-dimethylthio-2,4-toluenediamine and 3,5-dimethylthio-2,6-toluenediamine curatives (Ethacure 300), and UV stabilizers TINUVIN 571 and TINUVIN 765. The second golf ball ("Formulation II") has a cover layer formed of a polyurethane composition including a reaction product of 4,4'-diphenylmethane diisocyanate ("MDI"), polytetramethylene ether glycol ("PTMEG"), a mixture of 3,5-dimethylthio-2,4-toluenediamine and 3,5-dimethylthio-2,6-tol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com