Method for operating and arrangement of a pneumatic piston engine

a technology piston engine, which is applied in the direction of reciprocating piston engine, positive displacement engine, engine with rotating cylinder, etc., can solve the problems of low reliability, affecting the operation of pneumatic piston engine, so as to achieve the effect of reducing the length of the piston stroke, and reducing the number of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Description of a One-Stage PPE

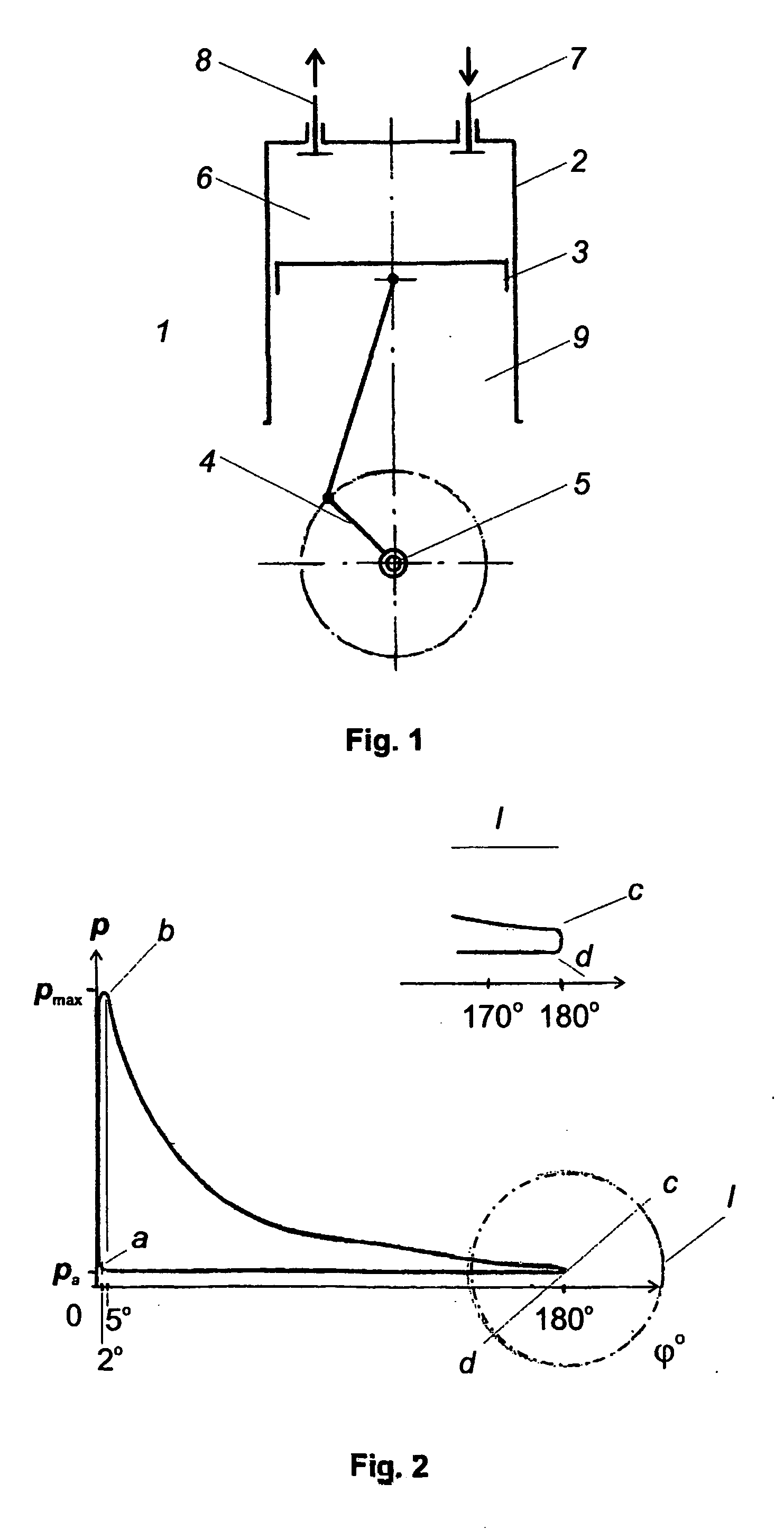

[0055] A one-stage one-sided supply pneumatic piston engine shown in FIG. 1 contains the following construction elements: 1--PPE, 2--cylinder, 3--piston, 4--crank, 5--crankshaft, 6--working chamber (over-cylinder space), 7--means for supply of compressed air (inlet valve), 8--means for exhaust of air (outlet valve), 9--under-cylinder space.

[0056] A PPE shown in FIG. 1 consists of a cylinder 2 containing a piston 3 kinematically joined via a crank 4 to crankshaft 5, and a working chamber 6 (over-cylinder space). The working chamber 6 contains a means 7 for supply of compressed air to the working chamber arranged as an inlet valve and a means 8 for exhaust of air, while the piston is in the region of bottom dead center, arranged as an outlet valve. The under-cylinder space 9 is bridged to atmosphere. The means 7 for supply of compressed air may be joined to an external source of compressed air.

[0057] The device according to the invention operates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com