Failure detection device for a rotation angle detection sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

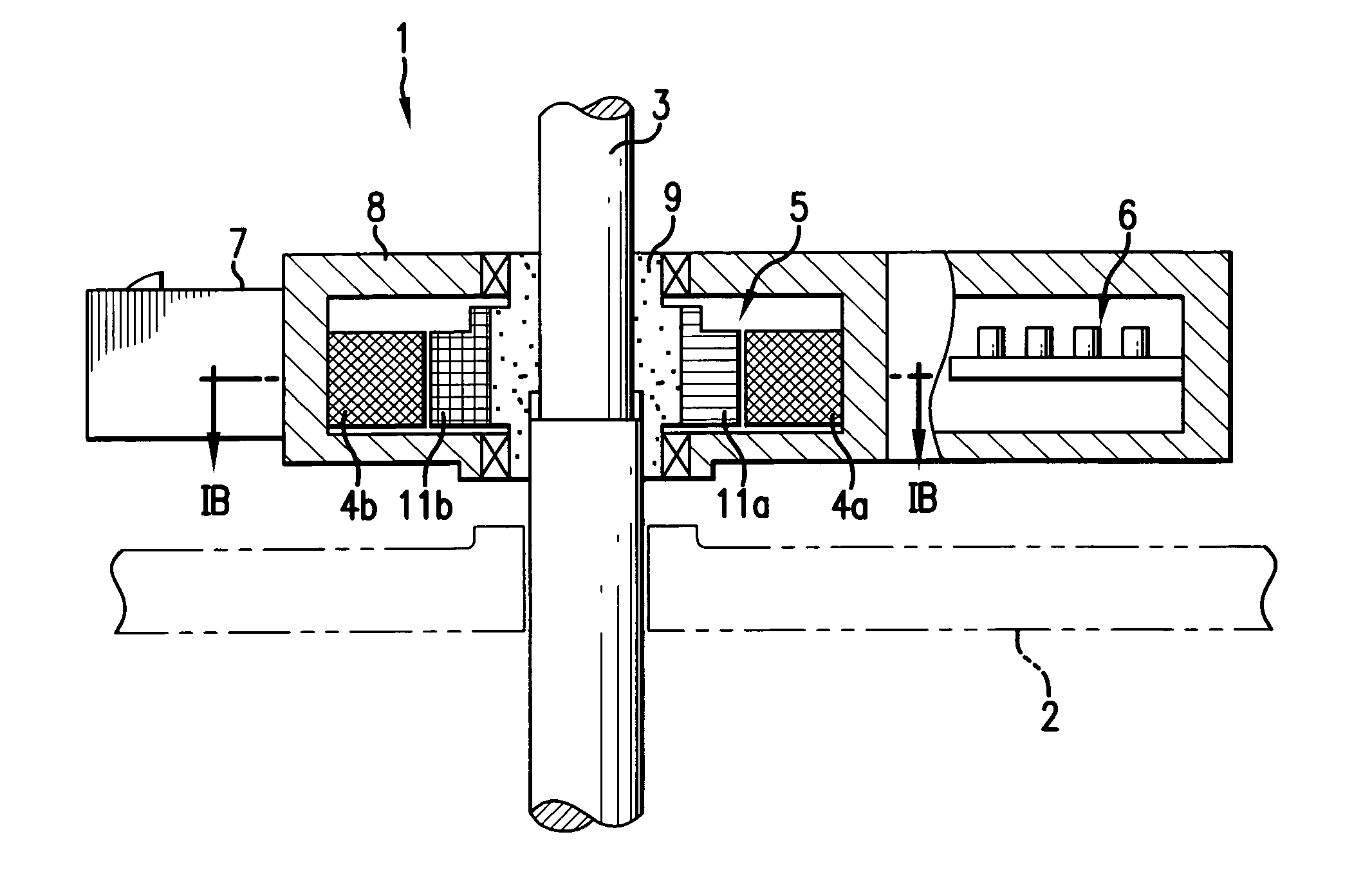

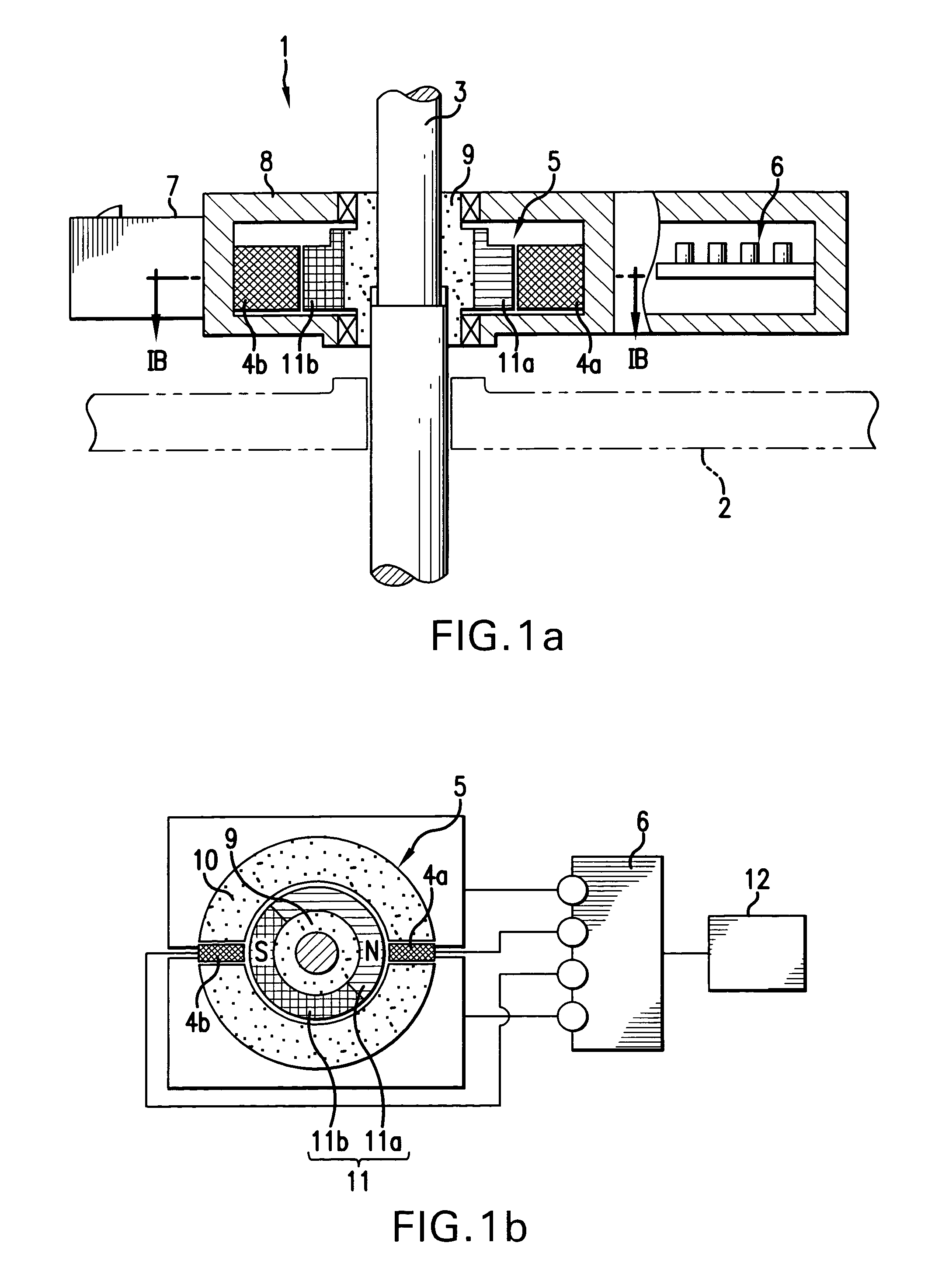

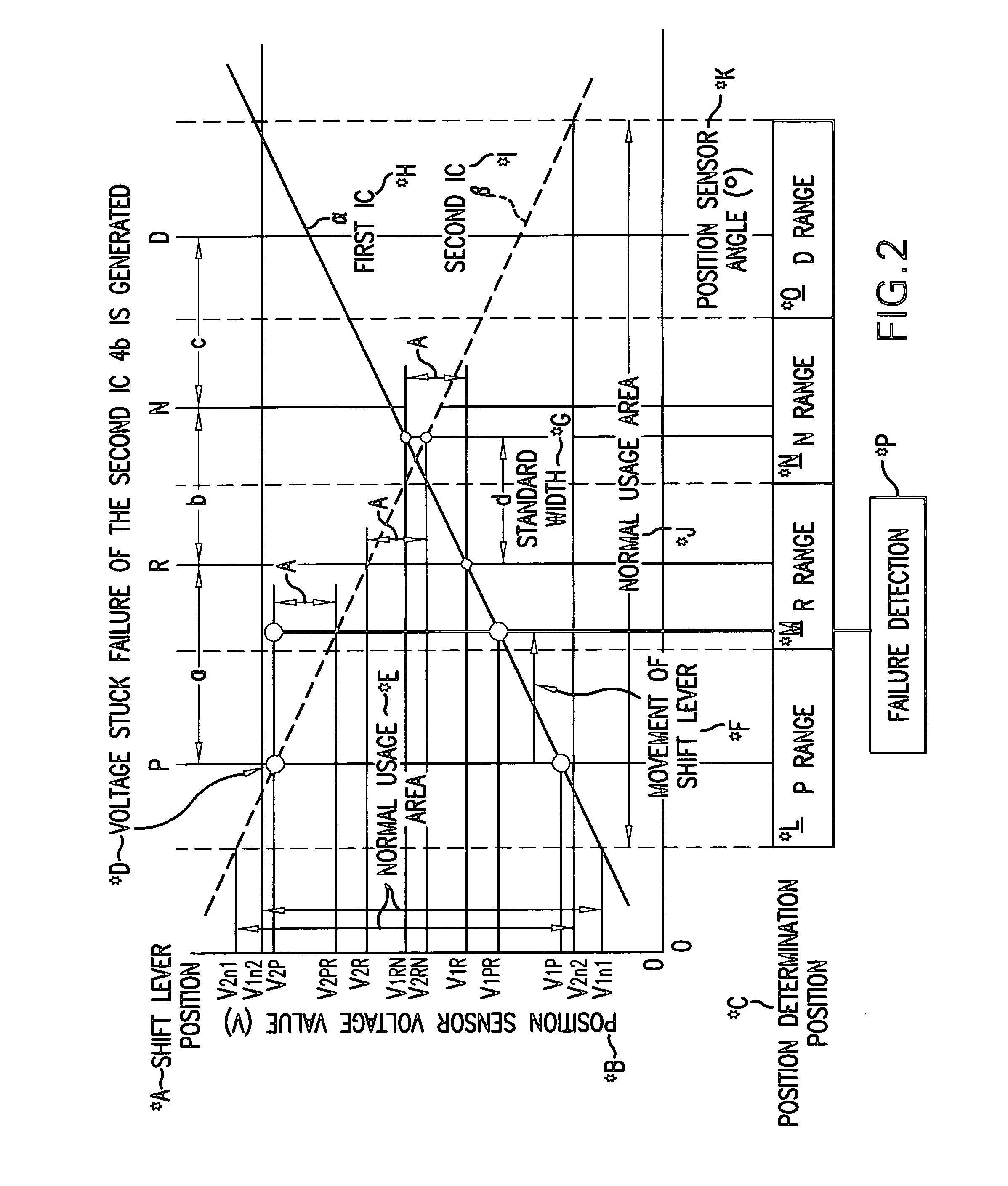

[0023]FIG. 1(a) is a diagram of a failure detection device for an angular position sensor, applied to an automatic transmission, according to a first embodiment of the invention; and FIG. 1(b) is a sectional view along the line IB-IB in FIG. 1(a).

[0024] As shown in FIG. 1(a) and FIG. 1(b), in this first embodiment, a failure detection device 1 for an angular position (rotational angle) sensor is applied in an A / T (automatic transmission). The position sensor failure detection device 1 is attached to a manual shaft 3 external to A / T case 2. The position sensor failure detection device 1 comprises angular position sensor 5 including first and second Hall effect transistors 4a and 4b as detection elements, an electronic control unit 6 (ECU, corresponding to a control unit in the embodiment of the invention) for controlling the A / T, A / T solenoids controlled by the ECU 6, a connecter 7 including plural terminals for connecting to plural controlled devices (i.e. an engine, an indicator),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com