Rolled paper feeding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

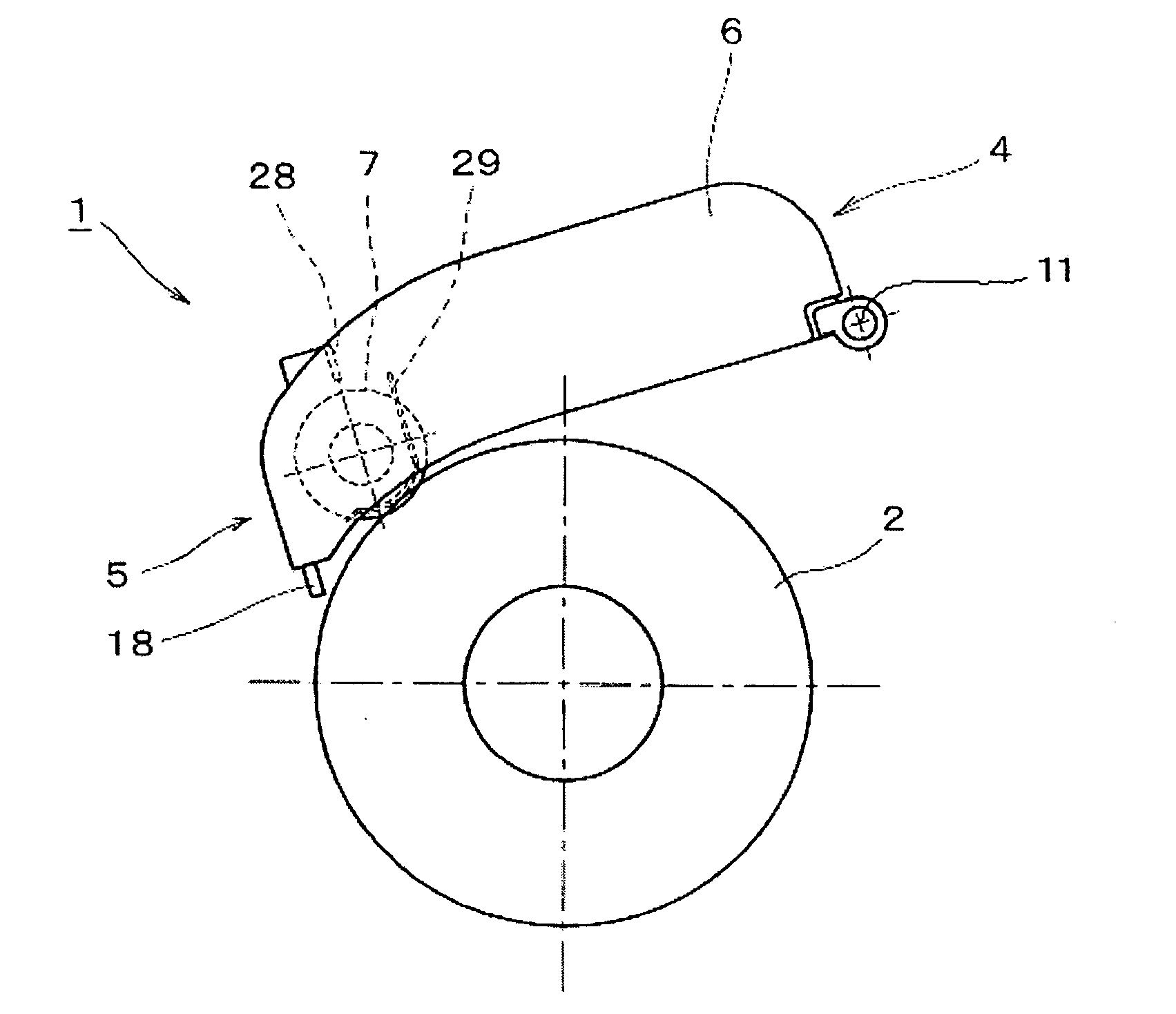

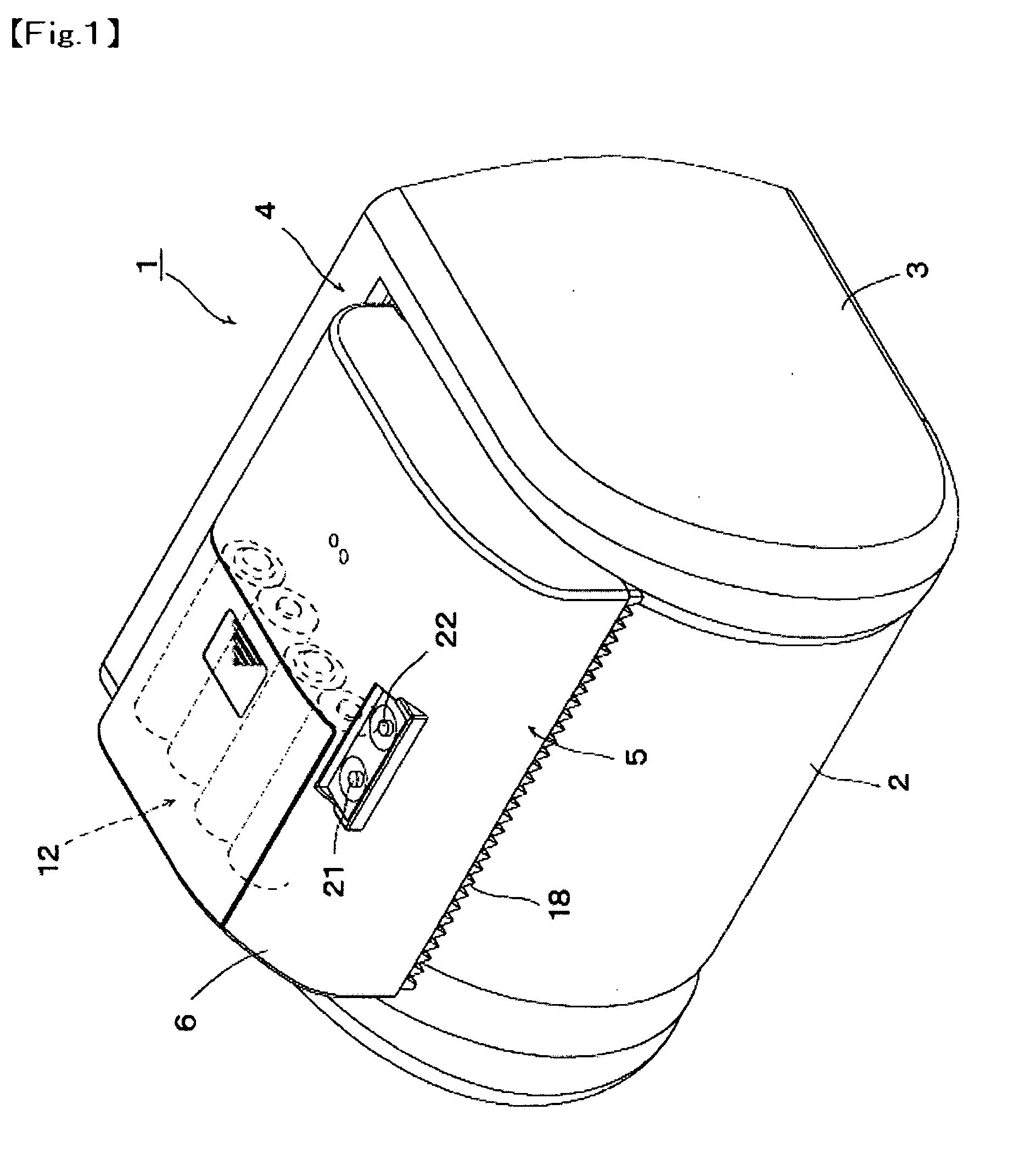

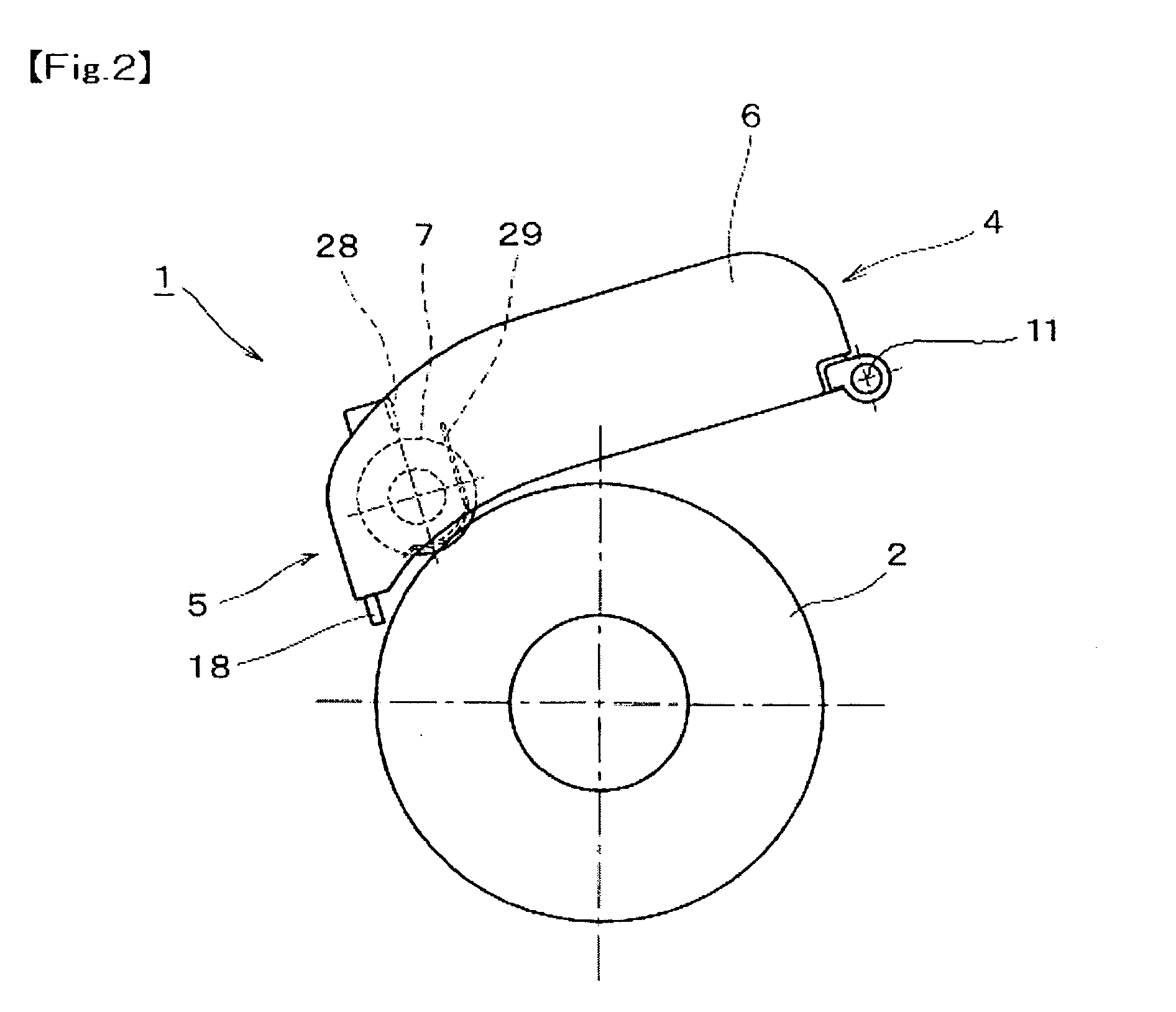

[0049] A rolled paper feeding device in accordance with an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0050] The rolled paper feeding device 1 includes, as shown in FIG. 1, a holder body 3 for rotatably supporting a rolled paper 2 and a cover part 6 whose one end part 4 is rotatably supported in a direction contacted with or separated from the rolled paper 2. The other end part 5 of the cover part 6 comes into contact with the rolled paper 2. Feed rollers 7 for feeding the paper of the rolled paper 2 and a drive part 8 for driving the feed rollers 7 to rotate are housed in the cover part 6. The feed rollers 7 are disposed on the other end part 5 side farther than the rotational center of the rolled paper 2. In addition, as shown in FIGS. 3 and 4, the drive part 8 includes a drive motor 13, a speed reducing mechanism 14 for transmitting the rotation of the motor 13 to the feed rollers 7 and an one way clutch 17 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com