Hydraulically entangled nonwoven material and method for making it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

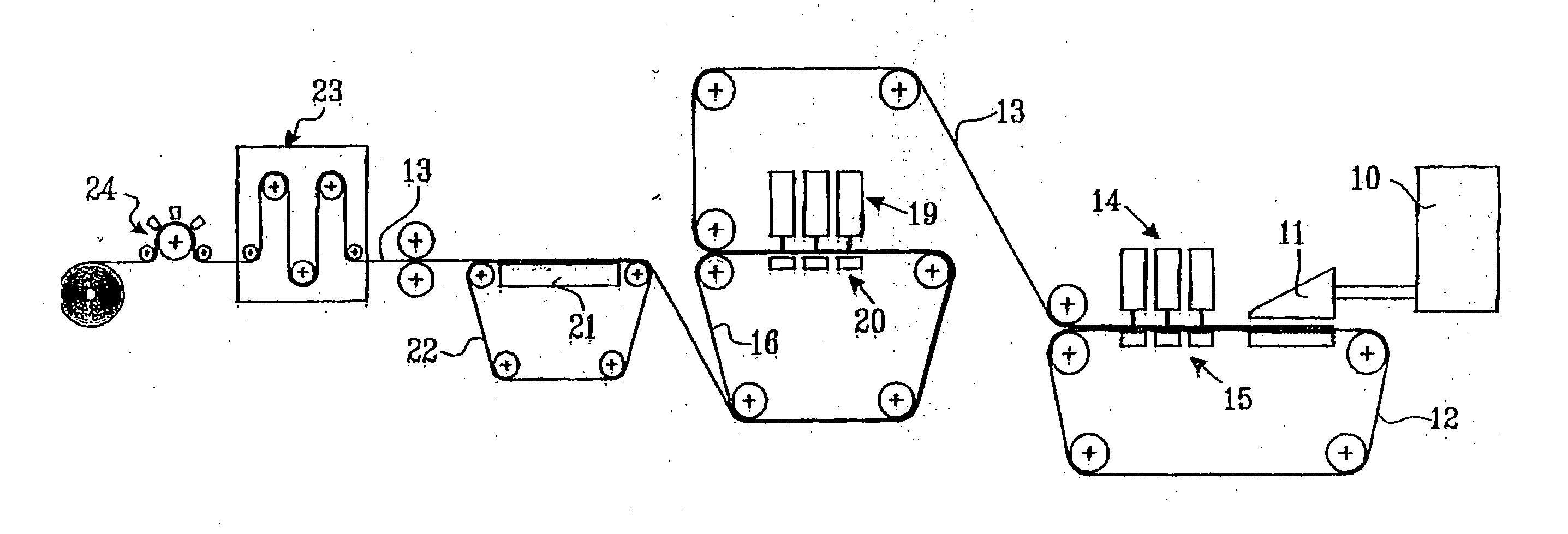

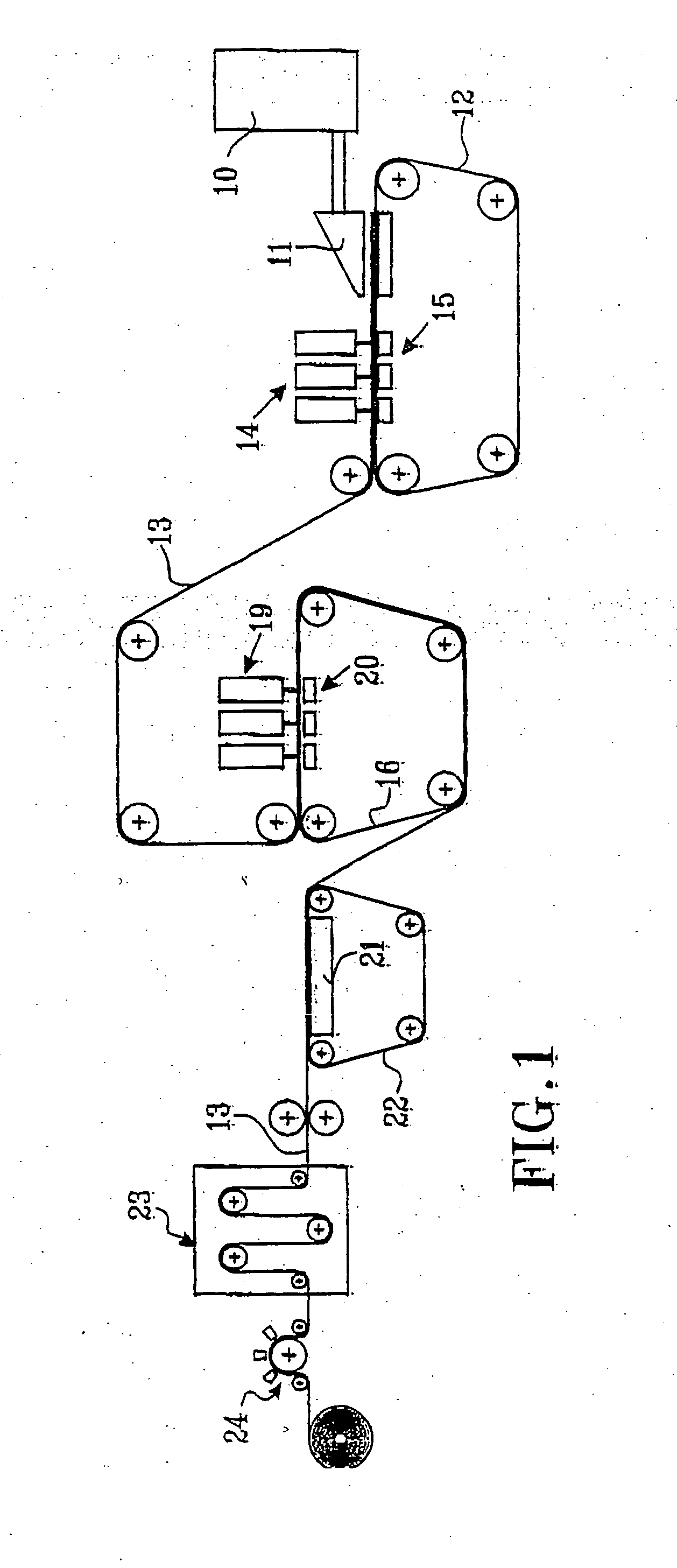

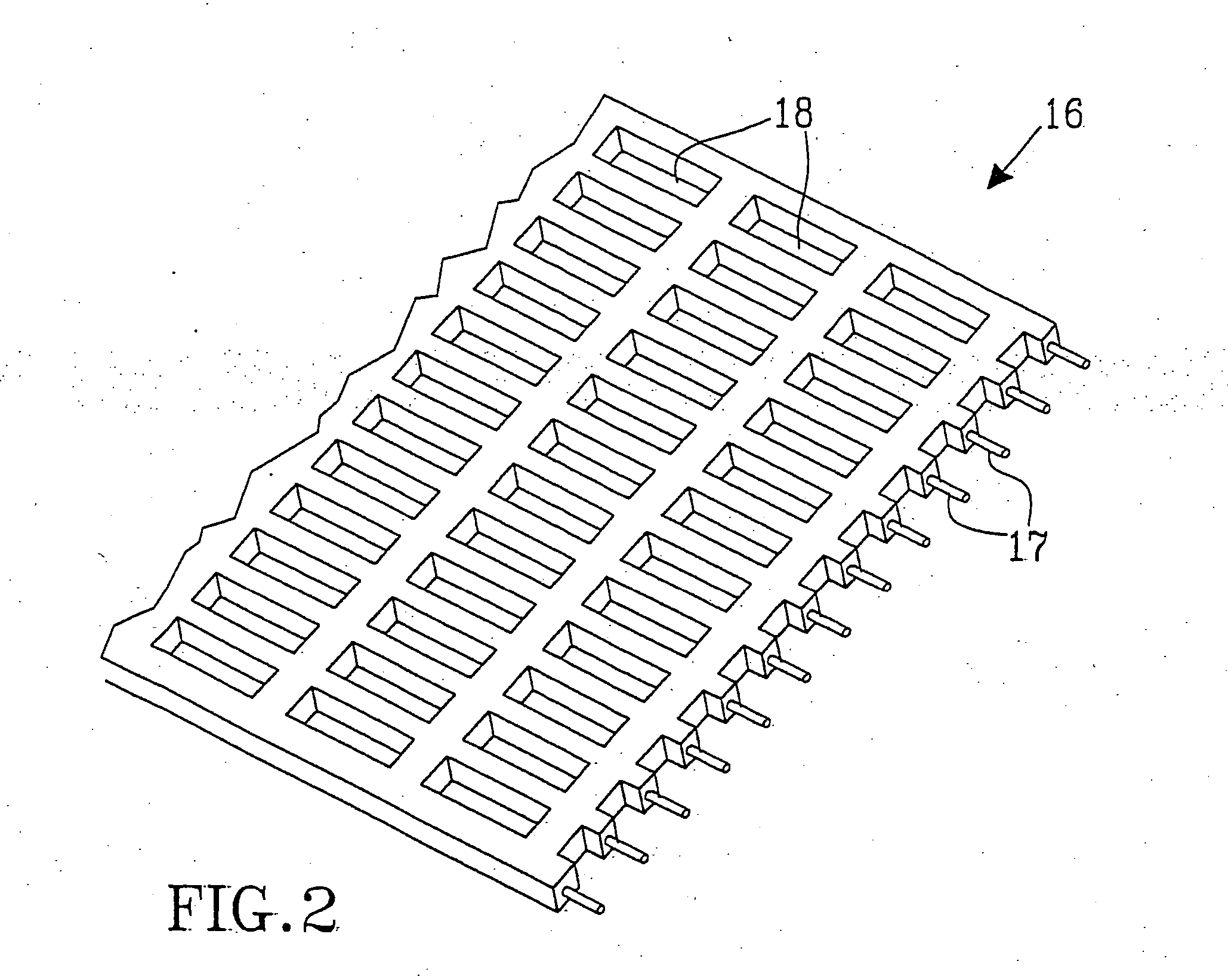

[0031] The device, which schematically is shown in FIG. 1, for manufacturing a so-called hydroentangled or spunlaced material, comprises a vessel 10, e g a pulper, in which a wet or foamed fibre dispersion is prepared, which via a headbox 11 is distributed on a foraminuous support member 12. This foraminuous support member 12 is preferably a wire of any conventional kind used in papermaking industry and which is suited for formation and for a first hydroentangling step to intertwine at least the man-made fibres present in the web The formed fibrous web 13 is then subjected to hydroentanglement from several rows of nozzles 14, from which water jets at a very high pressure are directed towards a fibrous web, while this is supported by the foraminous support member 12. The fibrous web is drained over suction boxes 15. Thereby, the water jets accomplish an entanglement of the fibrous web, i.e. an intertwining of the fibres. Appropriate pressures in the entanglement nozzles are adapted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com