Image capturing apparatus provided with image processor

a technology of image processing and image capturing apparatus, which is applied in the direction of instruments, television systems, color signal processing circuits, etc., can solve the problems of difficult to determine the white saturation level based on this convex portion, uniform illumination, and inability to obtain suitable -characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

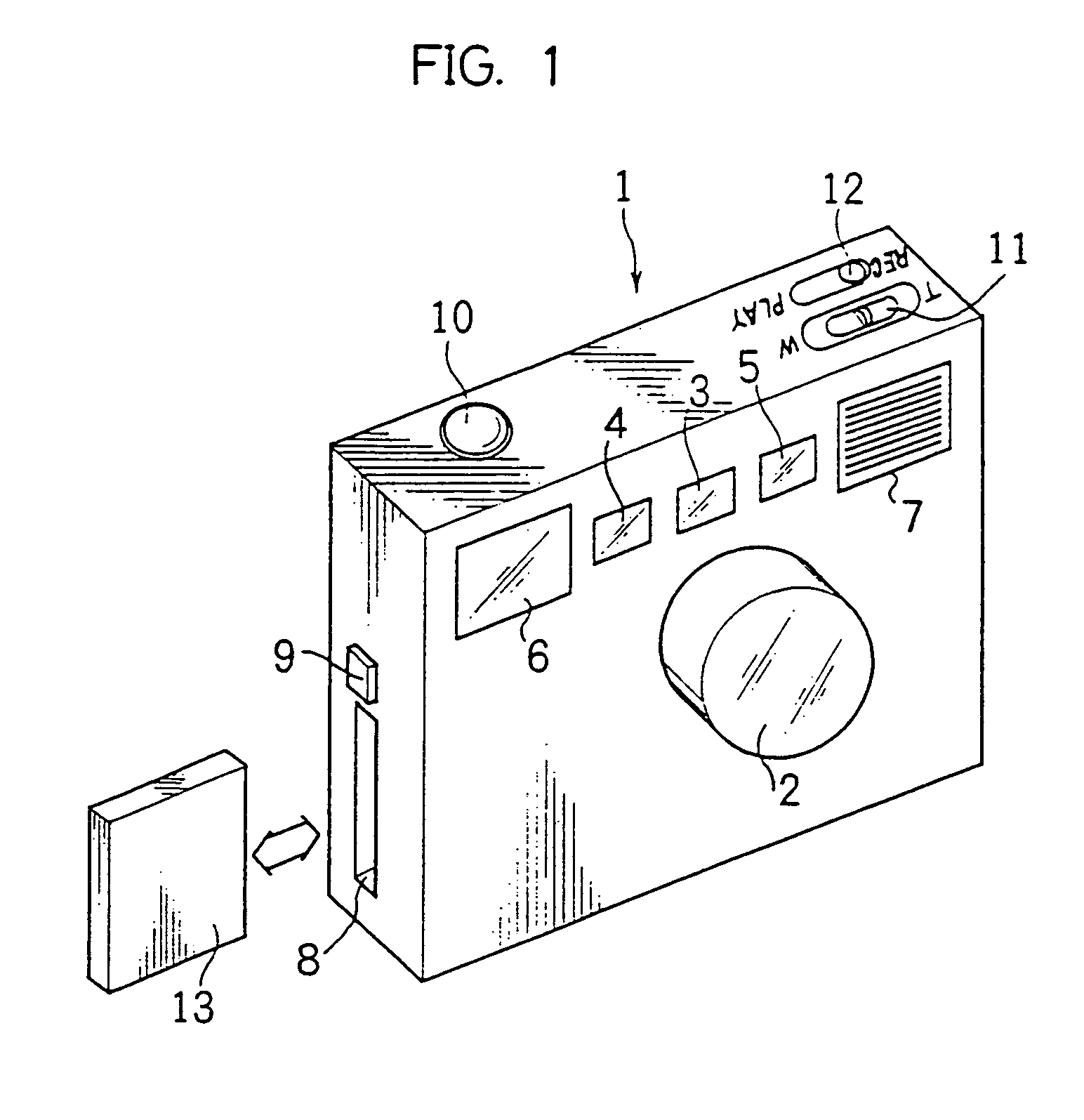

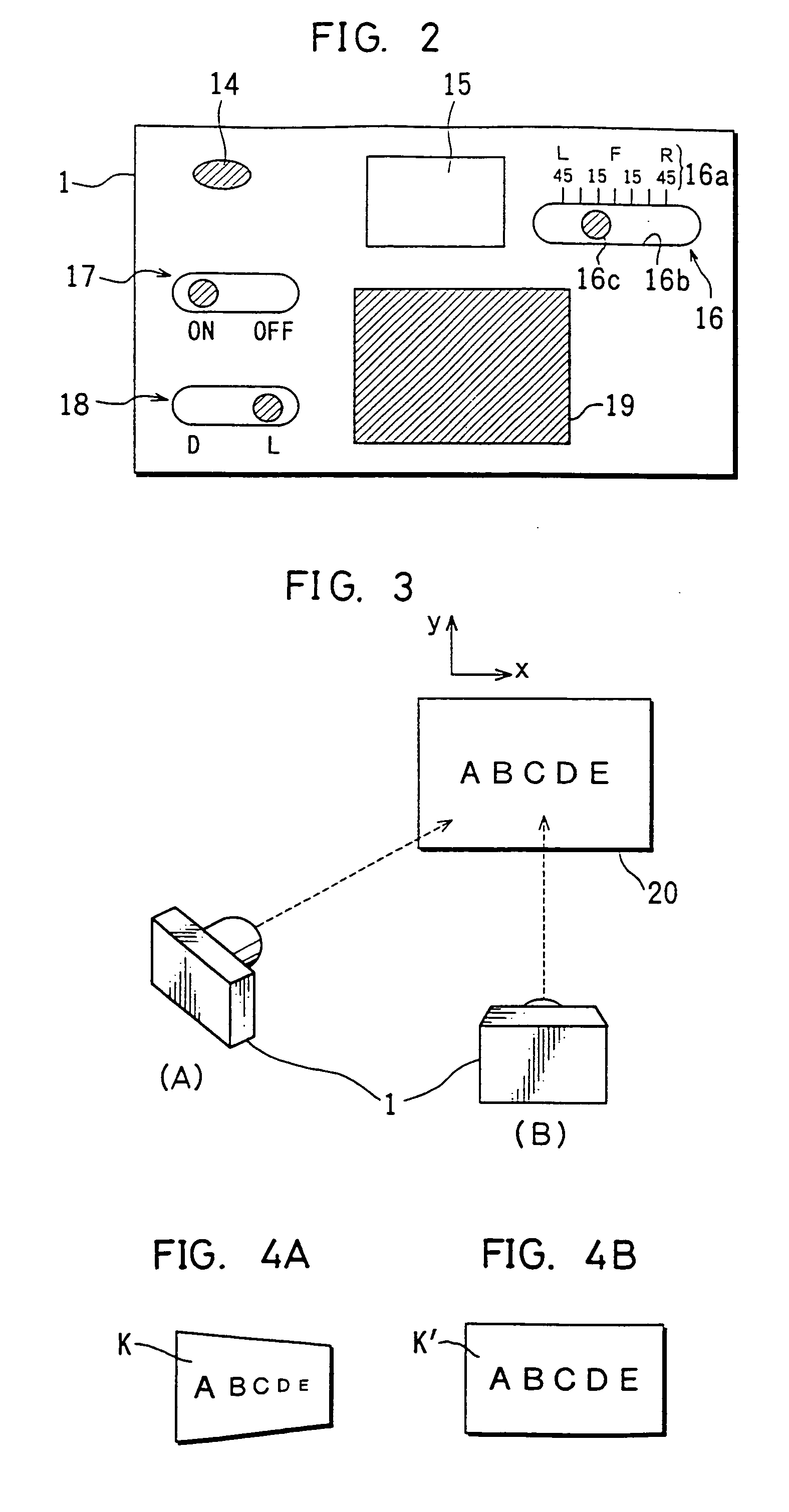

[0125]FIG. 1 is a perspective view showing an external configuration of an electronic camera according to the invention, and FIG. 2 is a rear view of this electronic camera.

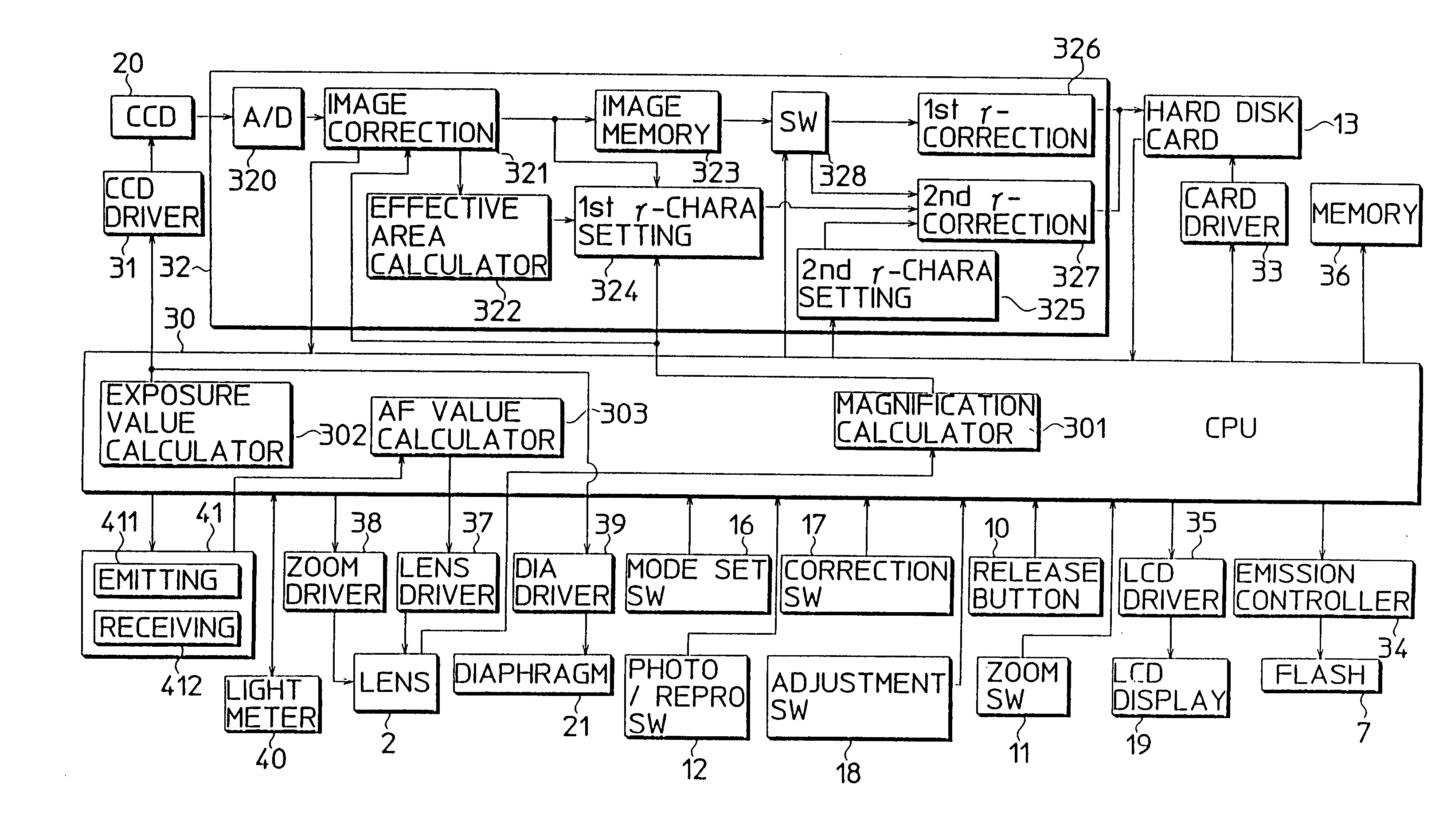

[0126] A camera 1 of FIGS. 1 and 2 includes a CCD area sensor as an image pickup device. An image data sensed by this CCD area sensor is recorded in an unillustrated hard disk card of PCMCIA standards. Although a case where the area sensor is used as an image pickup device is described in this embodiment, an image data may be picked by scanning an object light image by a line sensor.

[0127] The camera 1 is provided with a function of correcting an image of an object whose surface is not parallel with the sensing surface of the CCD area sensor (hereinafter, “oblique image”) into an image of an object whose surface is parallel with the sensing surface of the CCD area sensor (hereinafter, “front image”). Hereinafter, the above correction is referred to as an oblique image capturing correction.

[0128] For example, in...

second embodiment

[0287] Next, an image capturing control of the electronic camera 1 is described with reference to flowcharts of FIGS. 40 to 43.

[0288] FIGS. 40 to 42 are a main routine of the image capturing control. The image capturing procedure of the electronic camera 1 of the second embodiment is mostly common to that of the electronic camera 1 of the first embodiment. Specifically, the flowchart shown in FIGS. 40 to 42 differ from that of FIGS. 28 to 30 in that Steps #32, #54 are deleted and a processing of Steps #73-1 to 73-3 is inserted between Steps #72 and #74 instead of Steps #60 to #64.

[0289] The processing of Step #32 is deleted because it concerns the data effective area calculator 322 which is not provided in the second embodiment. The processing of Step #54 is deleted because it concerns the oblique image correction and is, accordingly, not necessary before the illuminance nonuniformity correction in the second embodiment in which the oblique image correction is performed after the ...

third embodiment

[0370] The electronic camera 1 of the third embodiment is provided with a function of preventing an occurrence of an undesired event where a character representation having become unclear due to the regular reflection of the illumination light (including both natural light and flash light) becomes even more unclear when the illuminance nonuniformity correction is applied to a picked image including a light image regularly reflected by an object. Since this function concerns the illuminance nonuniformity correcting function, but not the oblique image correcting function, the elements relating to the oblique image correcting function are deleted from FIGS. 59 to 61 in order to simplified the description.

[0371] The method according to the third embodiment for the illuminance nonuniformity correction is basically same as the one described in the first embodiment. Accordingly, description is supplementarily given on the construction relating to a newly added function in the description b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com