Particle detection system

a particle detection and particle technology, applied in particle and sedimentation analysis, measurement devices, instruments, etc., to achieve the effect of accurate particle size determination and increased submicron particle detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

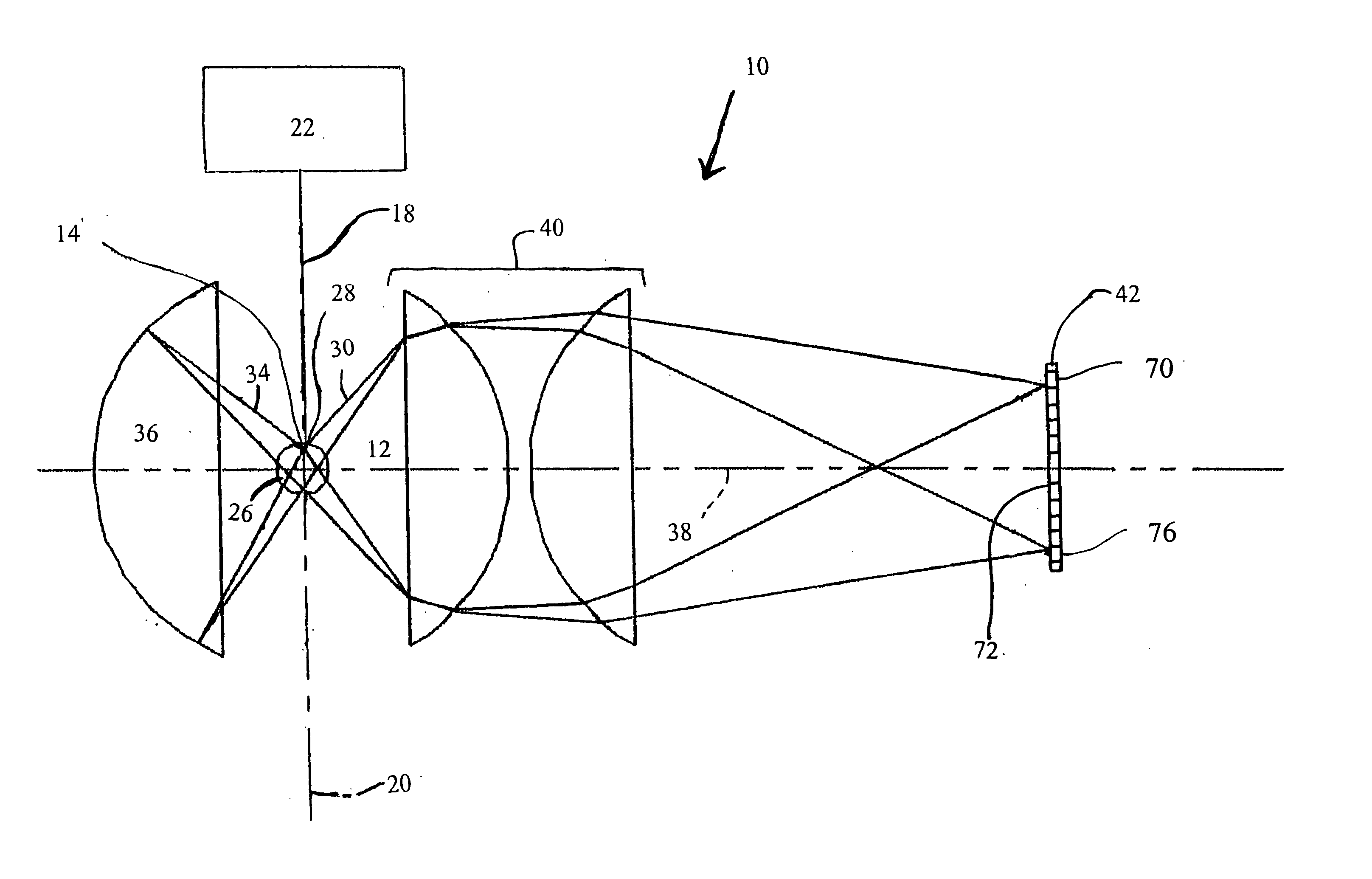

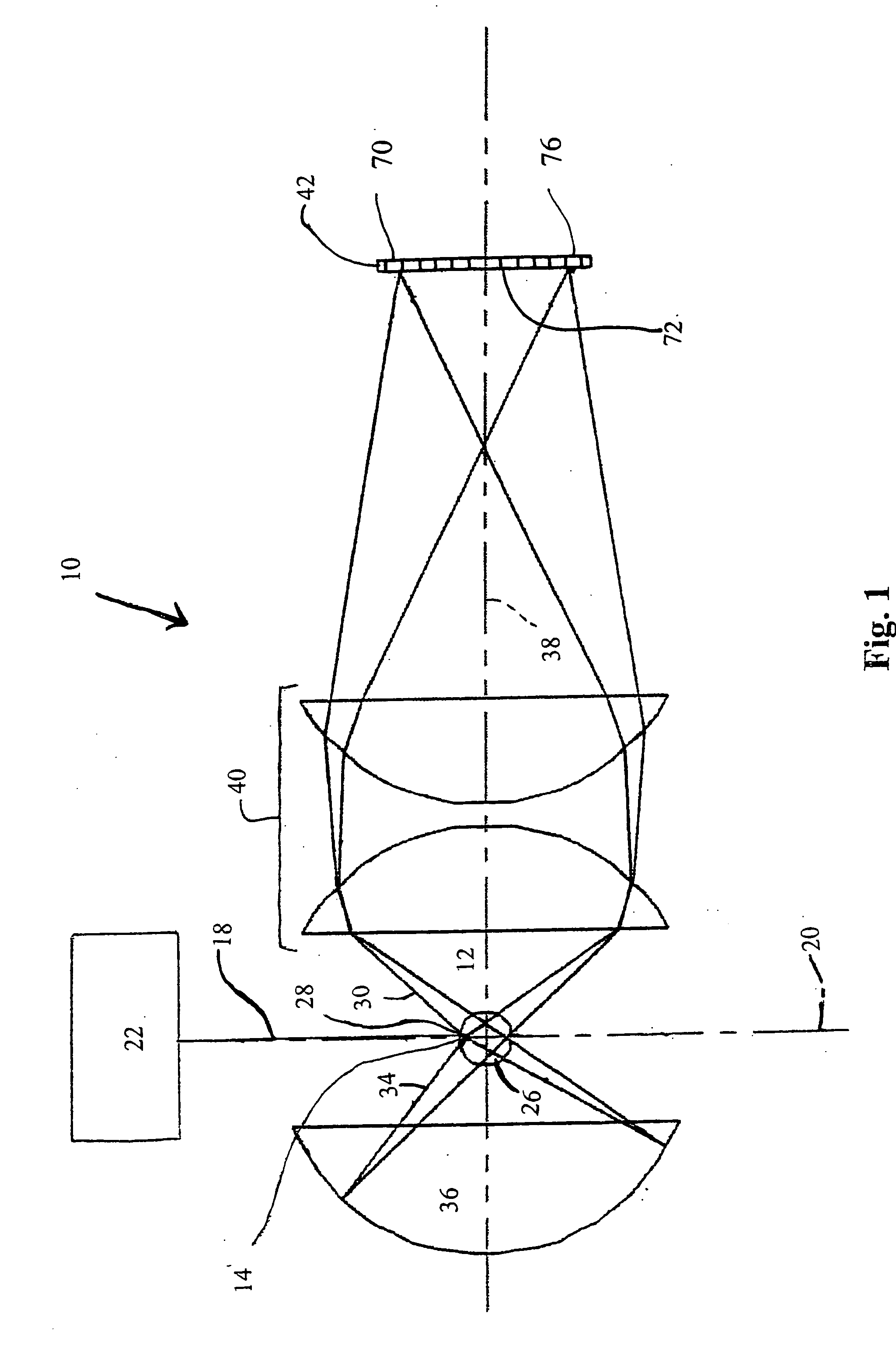

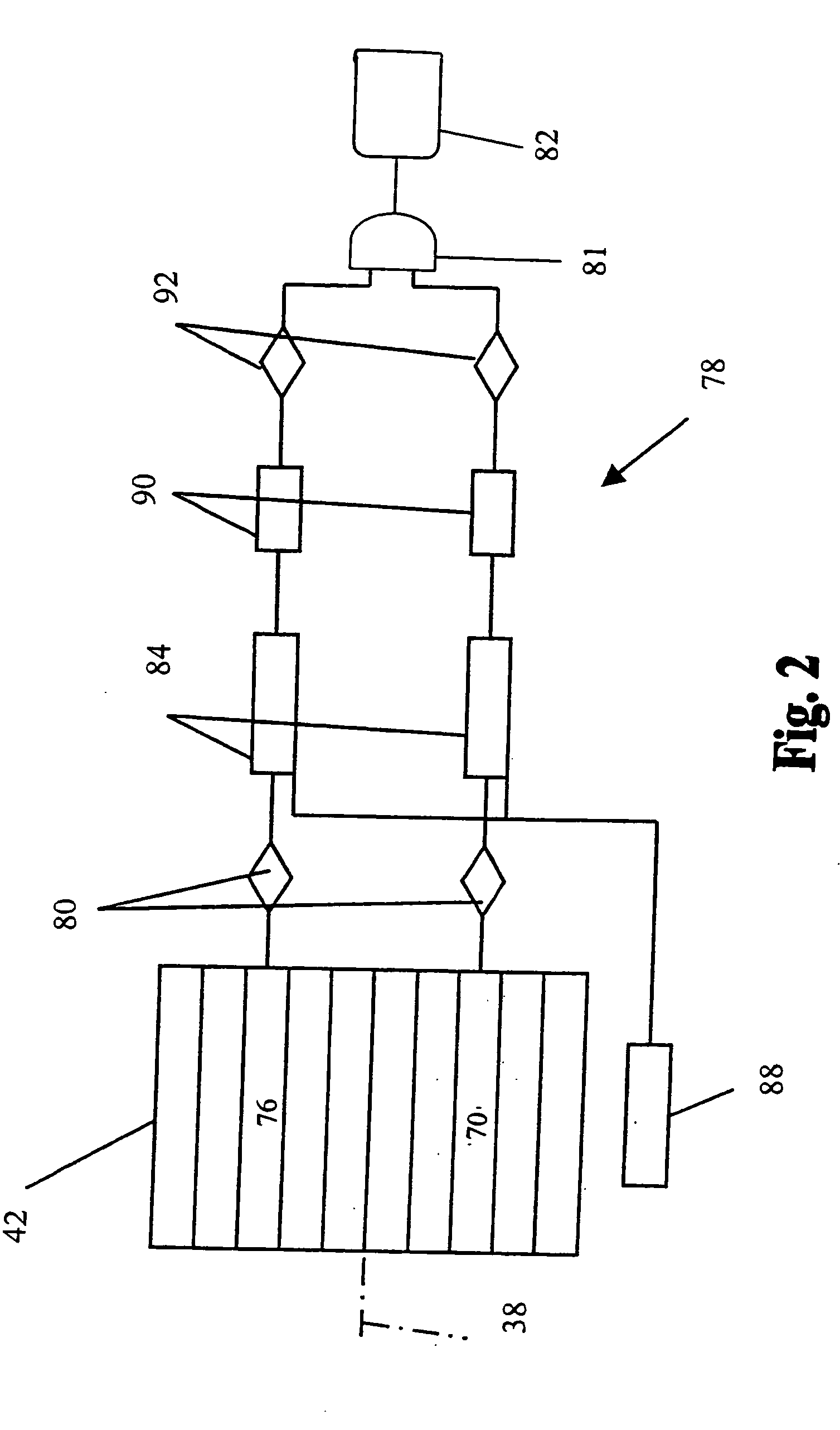

[0018] The particle detection system of the present invention has an increased ability to distinguish between noise and pulse output signals generated by small particles incident upon a light beam. This increased ability results from the incorporation of a light reflector, a pair of detector elements that detect correlated portions of a light beam scattered in multiple directions by a particle, and a coincidence circuit that determines whether the detector elements in the pair concurrently generate pulse output signals exceeding a predetermined threshold. If both detector elements of the pair concurrently generate pulse output signals, there is a high probability that the signals were caused by the incidence of a sample particle on the light beam rather than by noise variations in the particle detection system. The ability of the particle detection system of the present invention to distinguish low-amplitude pulse output signals from noise enables the system to detect smaller diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distances | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com