Absorbent article including airlaid mixture material containing thermoplastic fibers treated with phosphate ester or sulfate ester

a technology of thermoplastic fibers and airlaid mixtures, applied in the field of absorbent articles, can solve the problems of poor conformability of napkins to the body, and achieve the effects of improving fluid handling with viscous body fluids, superior fluid handling, and low stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

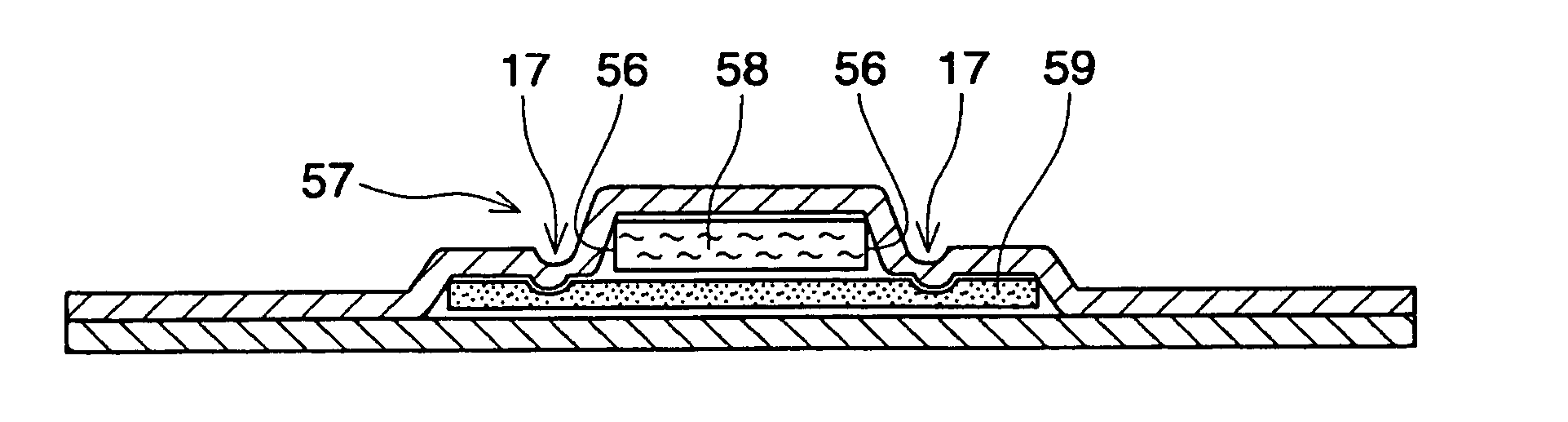

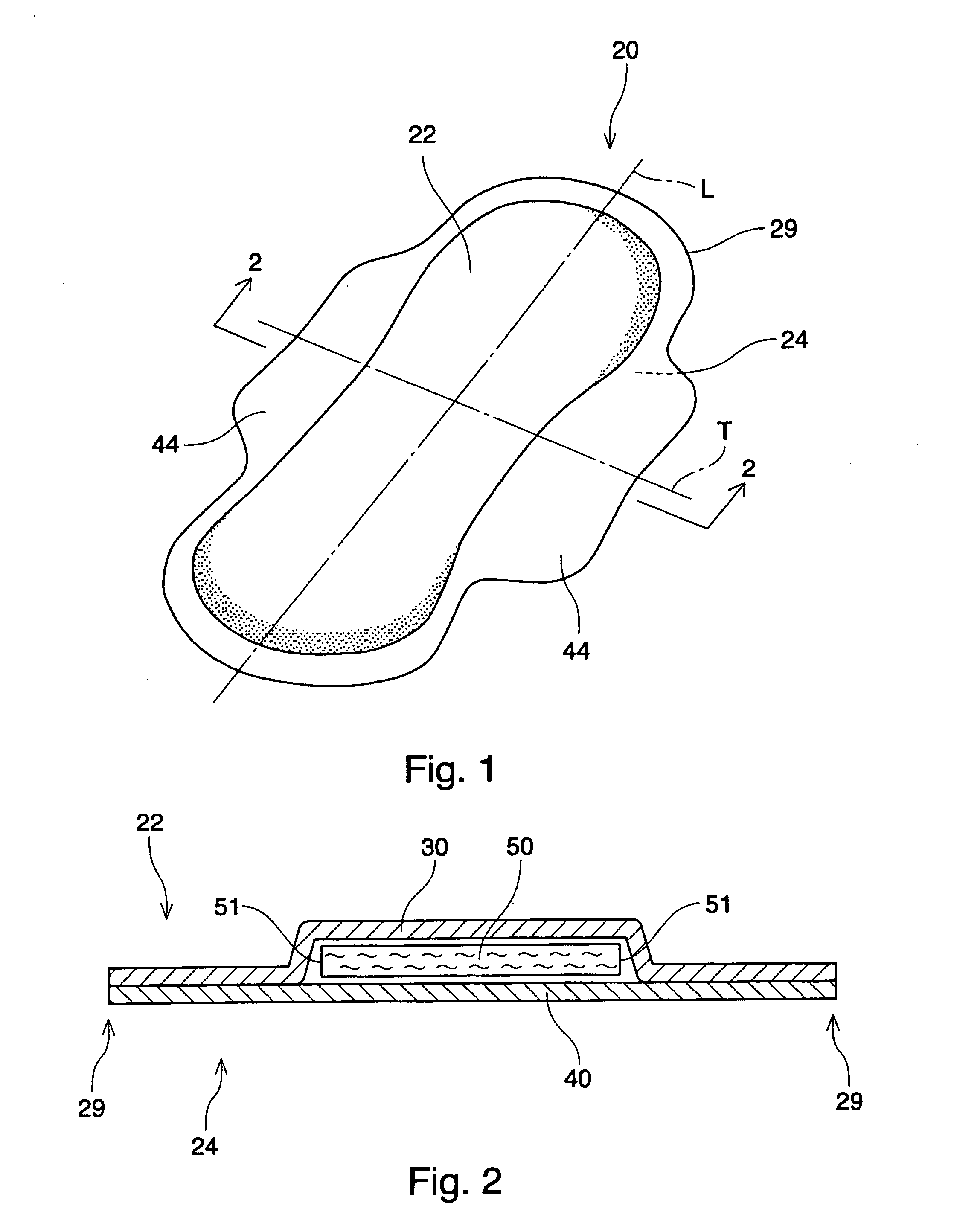

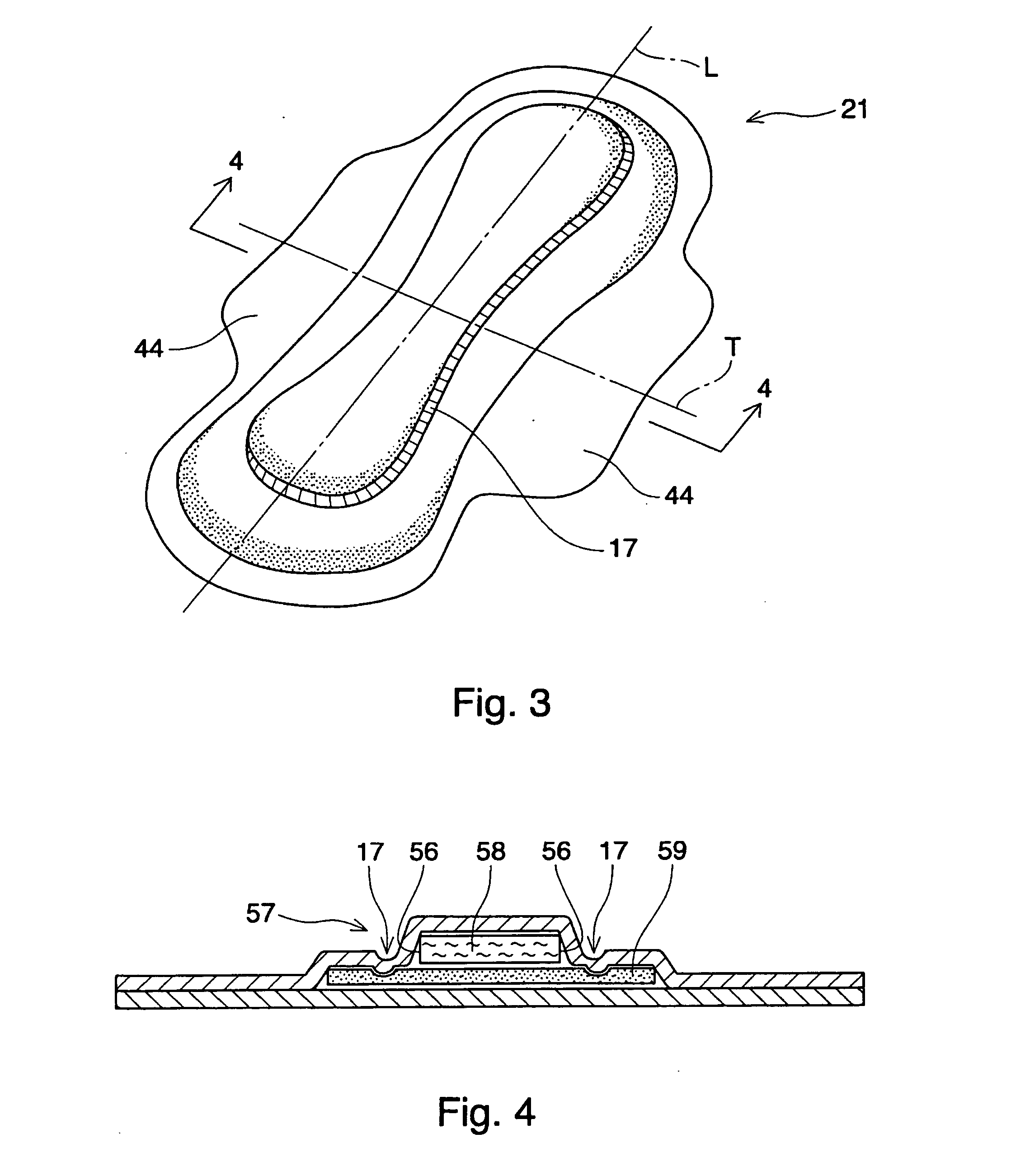

[0123] One layer of TBAM is produced from 82% of Kraft pulp fibers available from Rayonier Inc., GA, USA, under the trade name Rayfloc J-LD-E (“Pulp Fibers”) and 18% of acid modified polyethylene (in the sheath) / polypropylene (in the core) bicomponent fibers (1.7 decitex, 5.0 mm length) coated with a mixture of n-dodecyl (C12) phosphate ester potassium salts and n-octyl (C8) phosphate ester potassium salts, available from Chisso Corporation, Osaka, Japan, under Code No. XESC1015 (“Bico Fibers”) using an air-laying system available from M&J Fibretech A / S, Horsens, Denmark (“Air-lay System”). The subsequent thermal treatment is carried out at about 142° C. This material has basis weight of 100 g / m2 and thickness of about 2.0 mm at 20 gf / cm2 (i.e., 0.050 g / cc). This TBAM layer is preferably used as the absorbent core 50 in the embodiment shown in FIGS. 1 and 2.

example 2

[0124] One layer of TBAM is produced from 65% of Pulp Fibers, 18% of Bico Fibers, and 17% of particulate AGM which exhibit 7.3 g / g of absorption with Test Fluid mentioned using Air-lay System and subsequent thermal treatment at 153° C. This material has basis weight of about 100 g / m2 and thickness of about 2.0 mm at 20 gf / cm2 (i.e. 0.050 g / cc). This TBAM layer is preferably used as the absorbent core 50 in the embodiment shown in FIGS. 1 and 2.

example 3

[0125] One layer of TBAM is produced from 56% of Pulp Fibers, 18% of Bico Fibers, and 26% of particulate AGM which exhibit 7.3 g / g of absorption with Test Fluid mentioned using Air-lay System and subsequent thermal treatment at 150° C. This material has basis weight of about 100 g / m2 and thickness of about 1.2 mm at 20 gf / cm2 (i.e. 0.083 g / cc). This TBAM layer is preferably used as the absorbent core 50 in the embodiment shown in FIGS. 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com