Apparatus for positioning and stabbing pipe in a drilling rig derrick

a technology for positioning and stabbing pipes, which is applied in the direction of drilling pipes, drilling casings, borehole/well accessories, etc., can solve the problems of difficult, if not impossible, for rig workers to manually position the casing within the derrick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

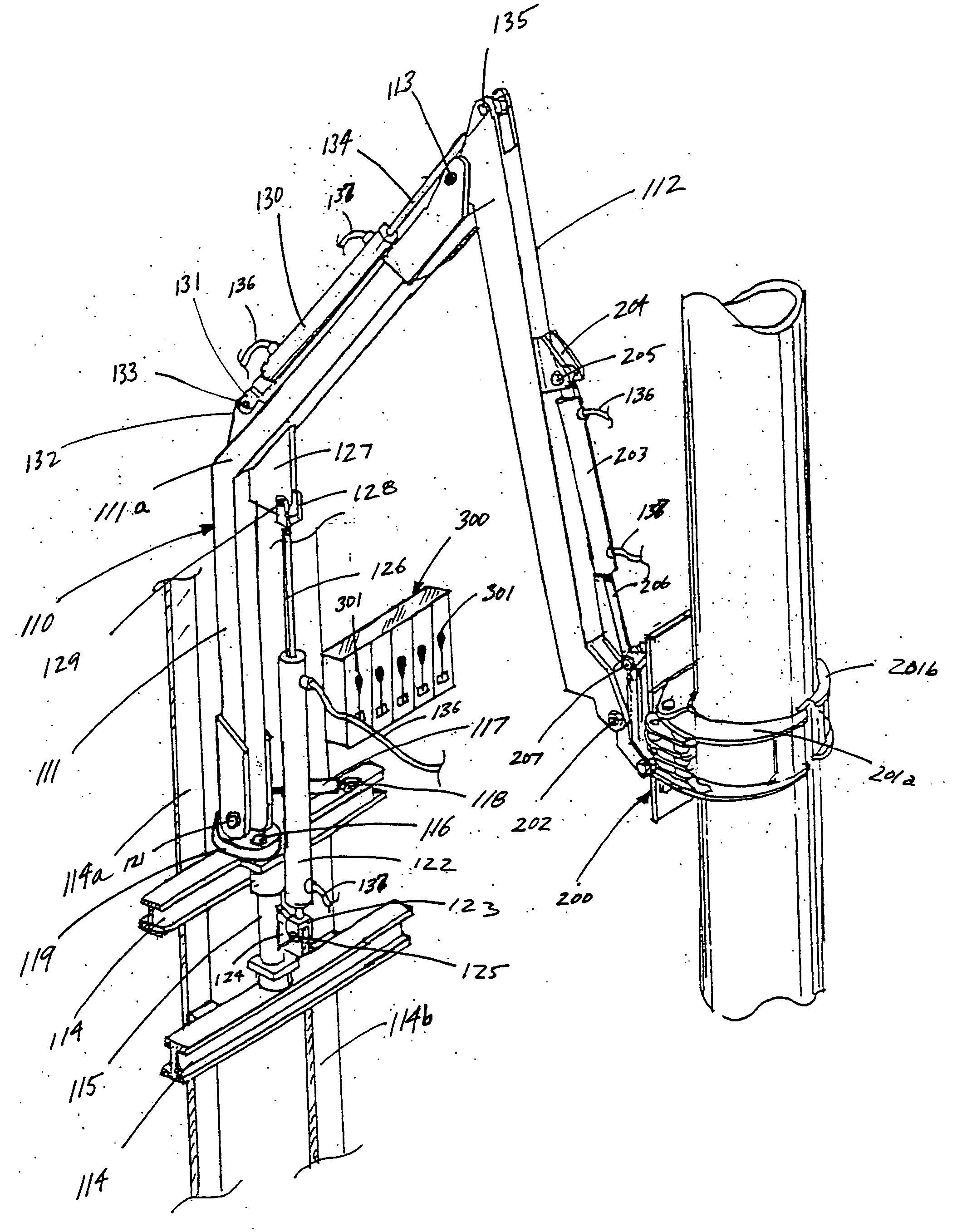

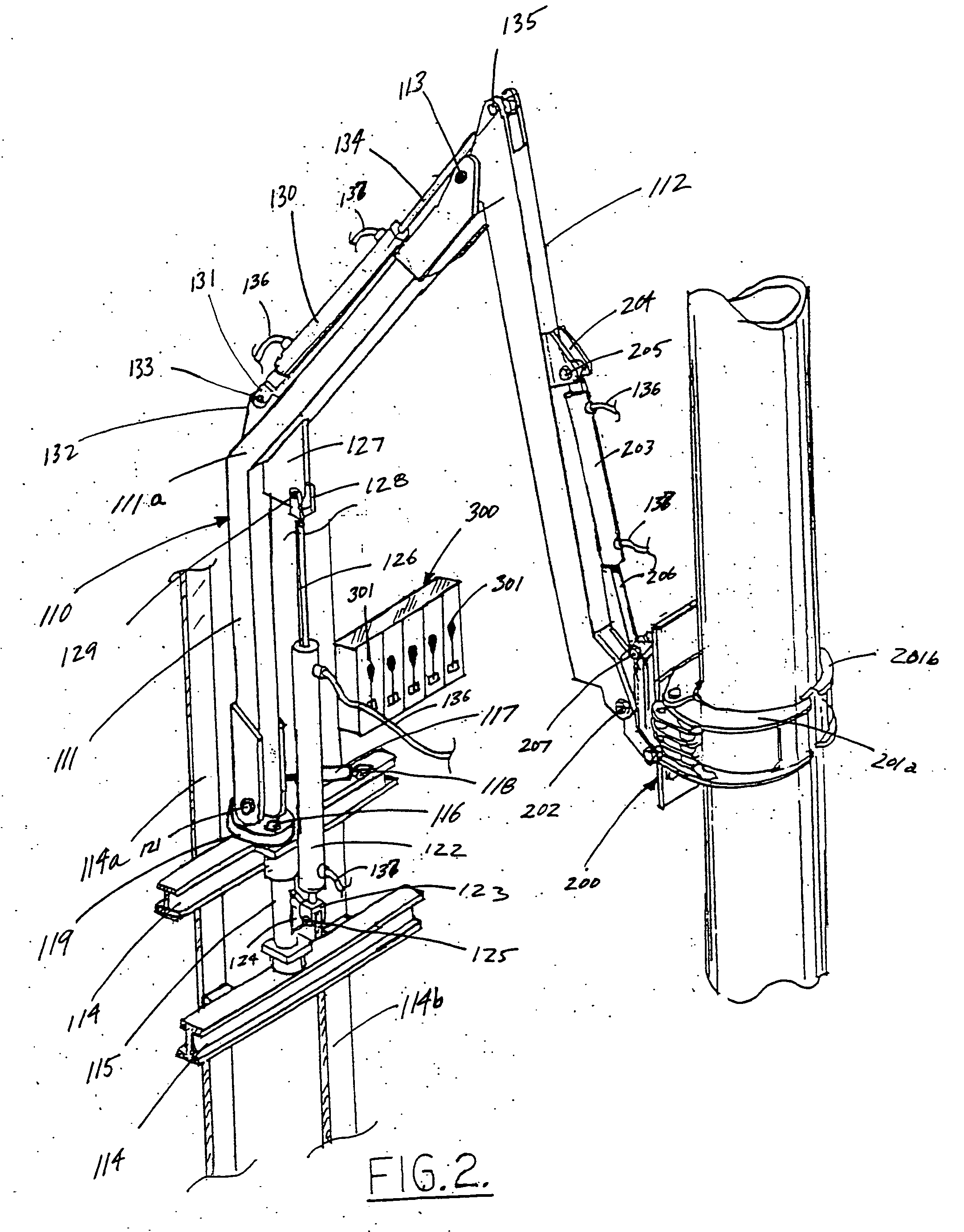

Image

Examples

Embodiment Construction

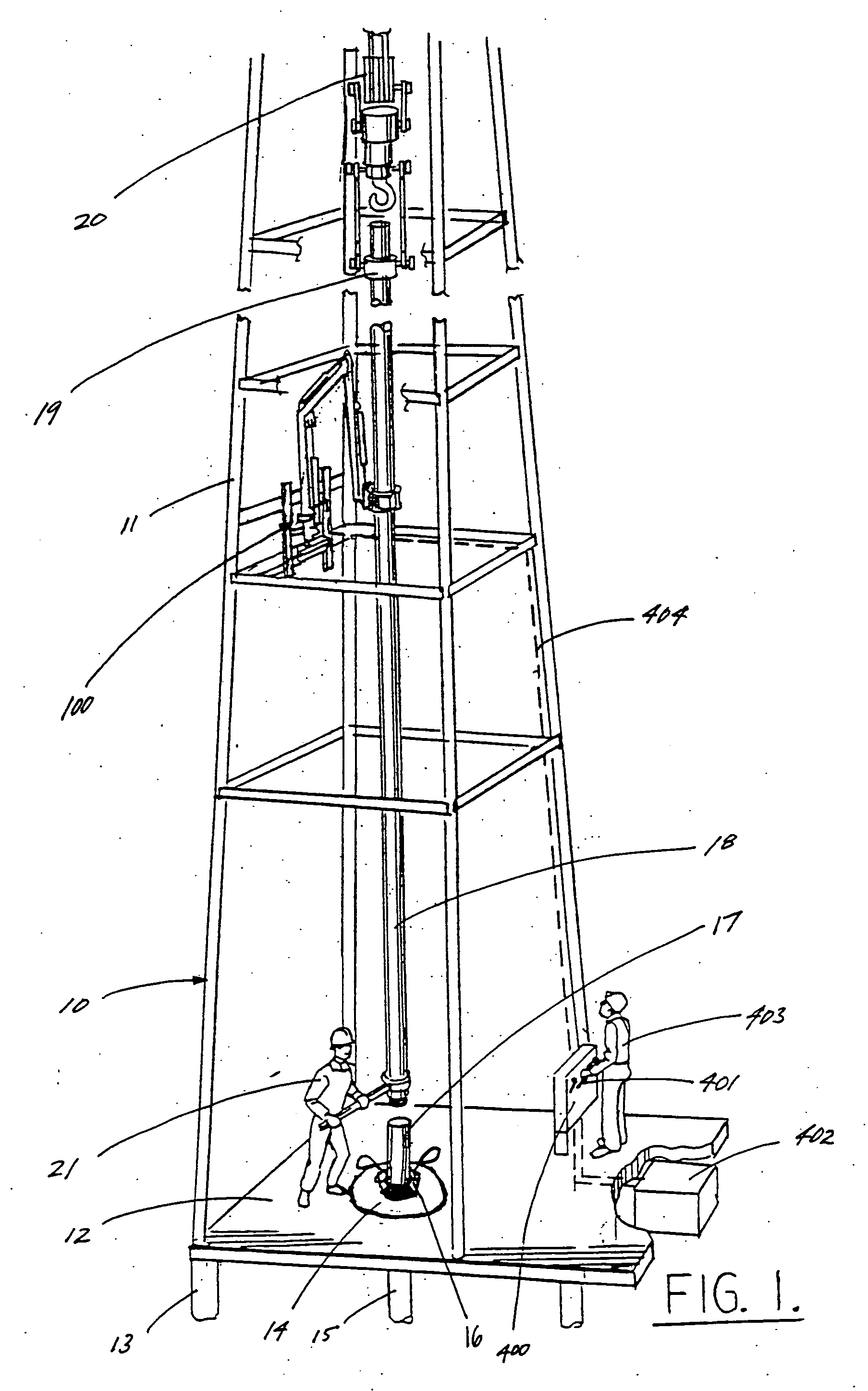

[0036] Referring initially to FIG. 1 of the drawings, drilling rig 10 is depicted during operations for the installation of casing into a well. Vertically extending derrick 11 and rig floor 12 are supported on drilling platform 13. Rotary 14, which is positioned on rig floor 12 at the surface of well 15, supports, by means of suitable lower slips 16, an elongated section of casing 17. The upper portion of casing section 17 protrudes out of rotary 14 and is situated above rig floor 12, while the remainder of casing section 17 projects downwardly from the rig floor and, ultimately, into the well 15 being drilled or serviced.

[0037] When installing casing into well 15, it is necessary to serially interconnect multiple sections of casing at a point of joinder a short distance above rig floor 12. The process is commenced by installing a first section of casing 17 into well 15, and hanging or suspending same in place using lower slips 16. As succeeding sections of casing are added to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com