Cope/drag interface sealing article for the metal casting industry, and method

a technology of metal casting and interface sealing, which is applied in the direction of moulding flaks, manufacturing tools, moulding apparatus, etc., can solve the problems of castings showing defects, epa violations, and hazardous working conditions for foundry personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]“approximately” one particular value and / or to “about” or “approximately” another particular value. When such a range is expressed, another embodiment includes from the one particular value and / or to the other particular value. Similarly, when values are expressed as approximations, by use of the antecedent “about,” it will be understood that the particular value forms another embodiment.

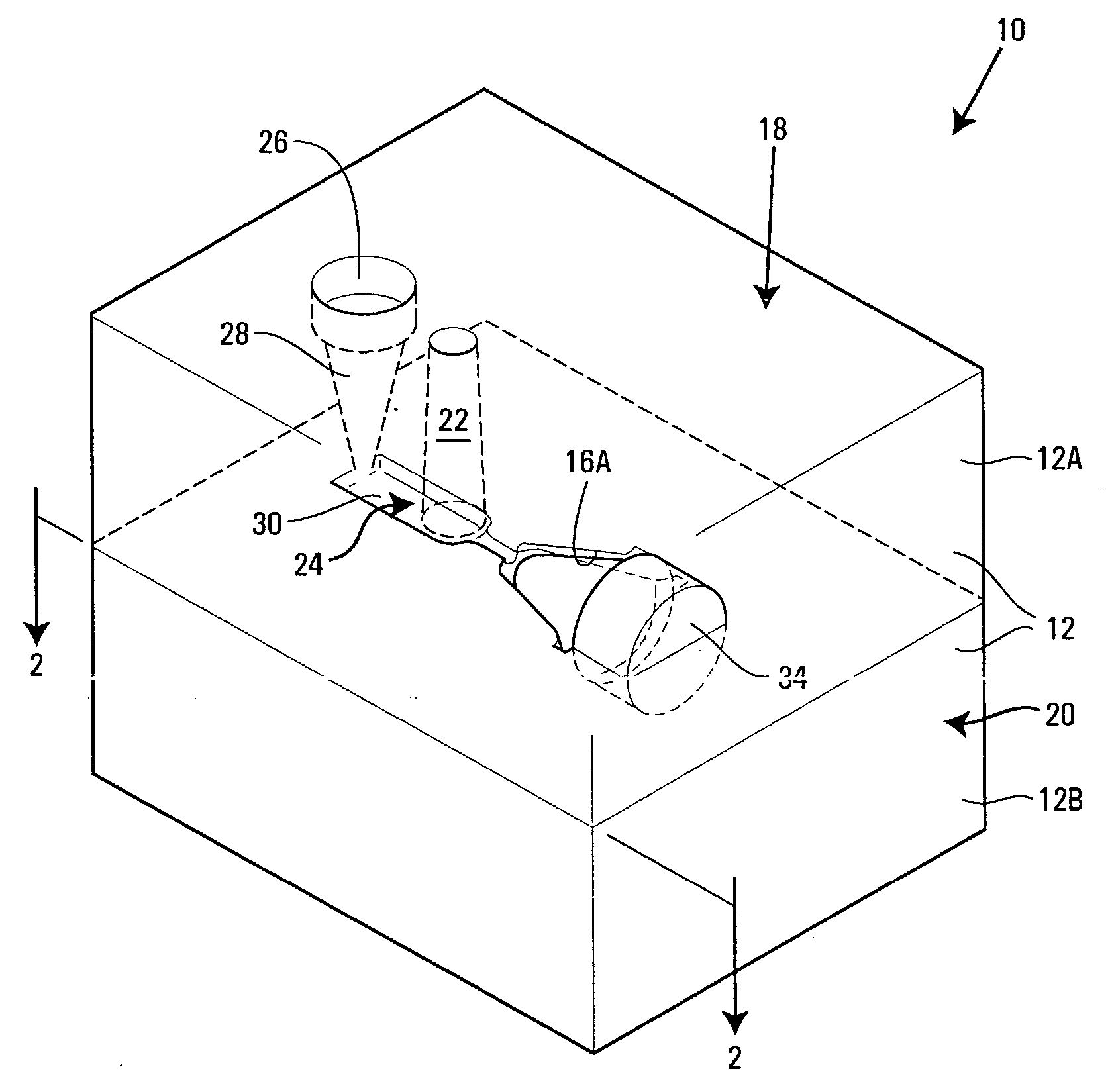

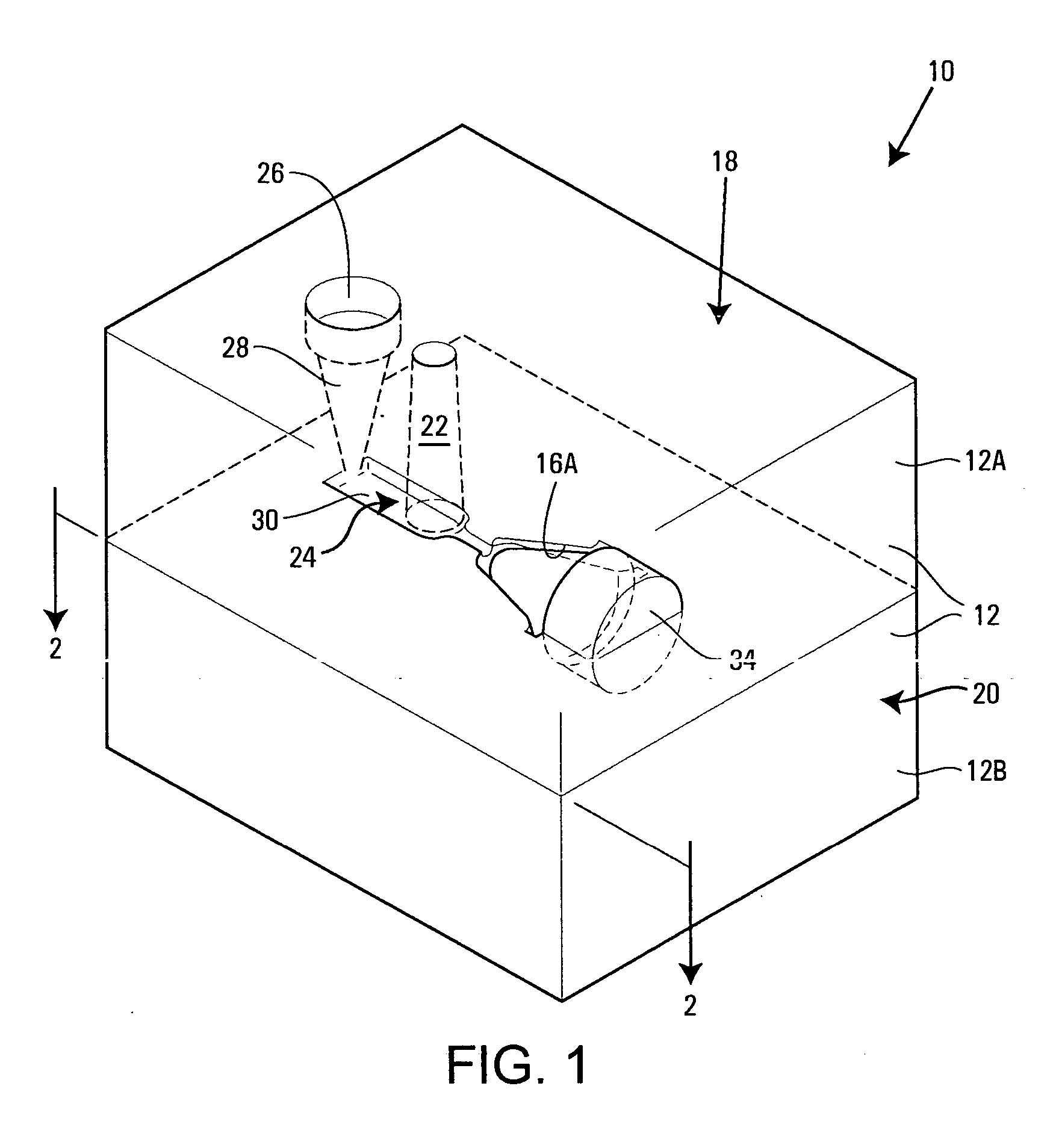

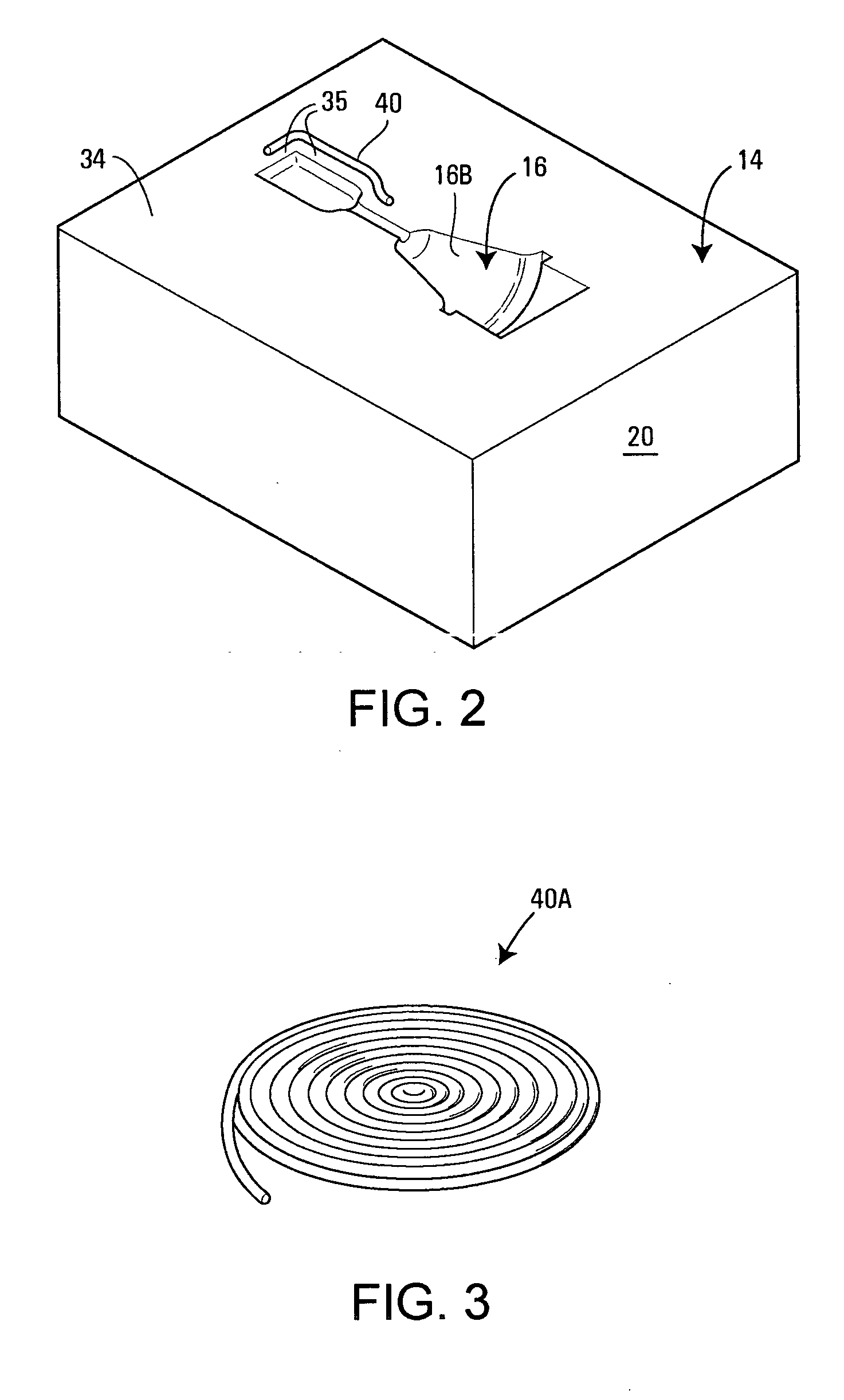

[0021] In brief, there is described herein a new and improved fiber-reinforced composition and article for use at an interface, between upper and lower mold portions, in casting metal parts in the foundry industry. The compositions used to form the sealing articles described herein comprise about 35% to about 65% by weight clay, preferably a smectite clay such as sodium montmorillonite, water in an amount about 5% to about 15% by weight; a hygroscopic agent, such as glycerin, in an amount of about 20% to about 60% by weight; and reinforcing fibers, synthetic or natural, such as cotton fibers....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com