Multi-piece machine tool base

a multi-piece machine tool and base technology, applied in the direction of manufacturing tools, rotary cutting tools, flat surfacing machines, etc., can solve the problems of largely inadequate portable planing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

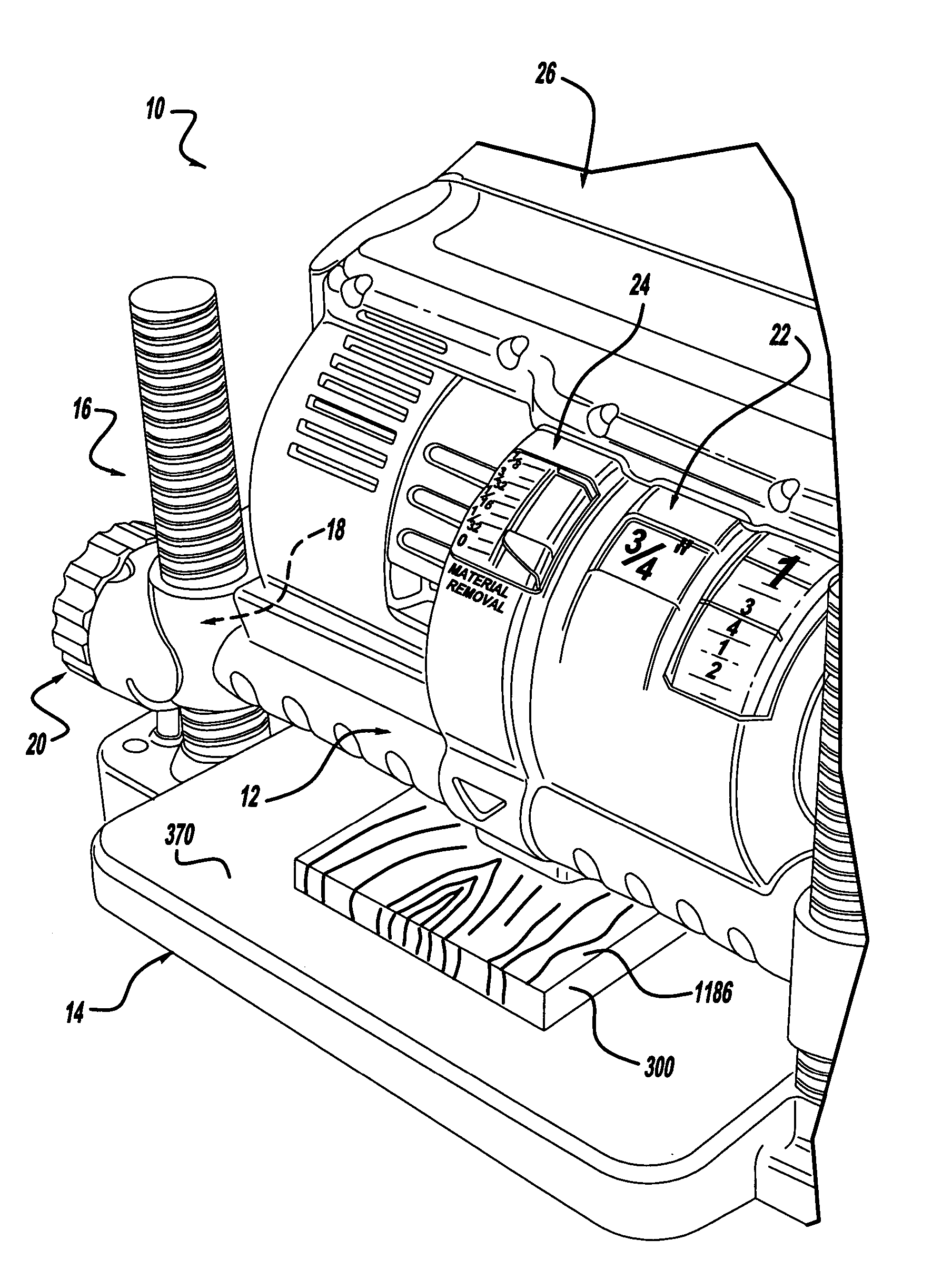

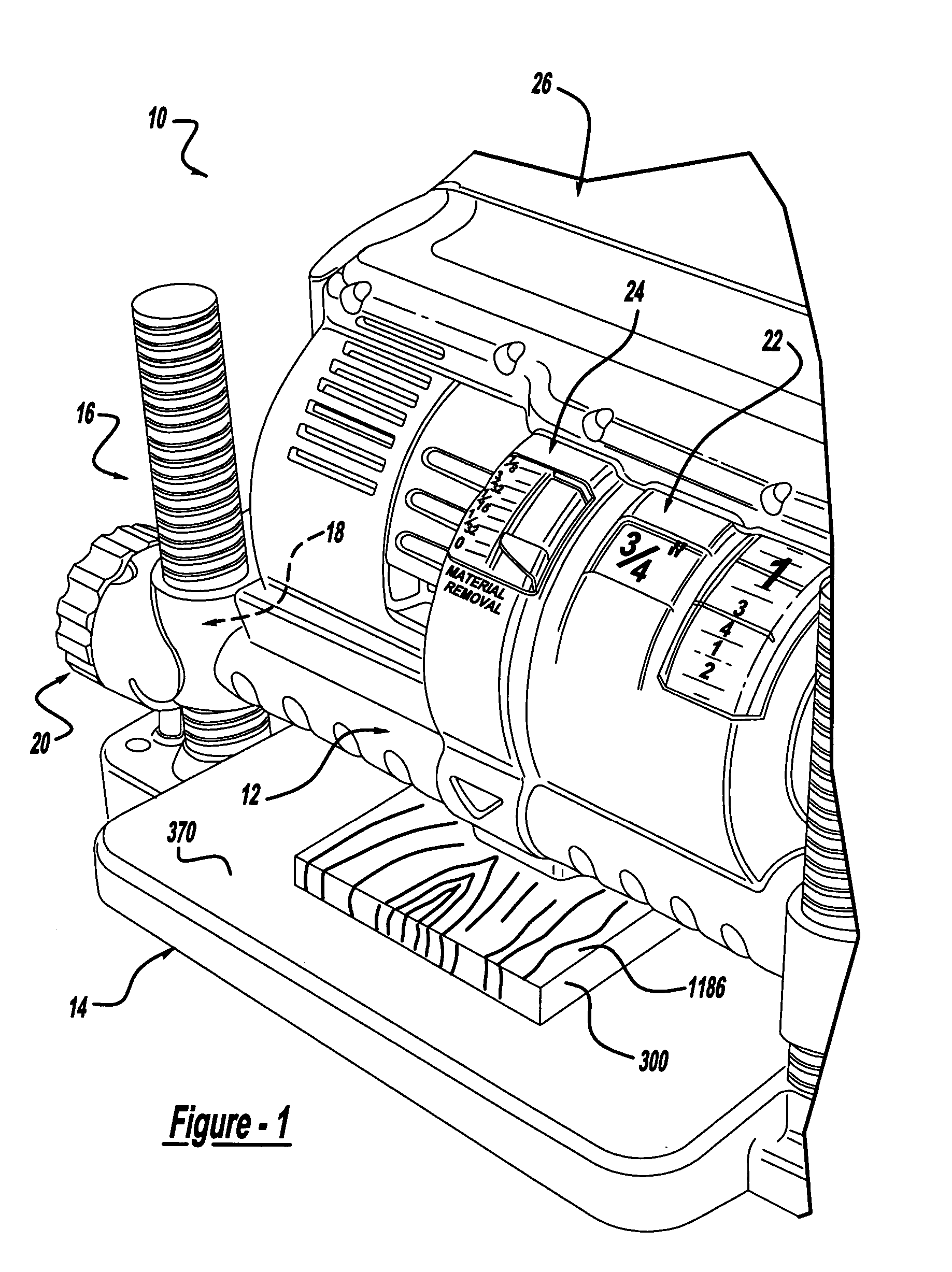

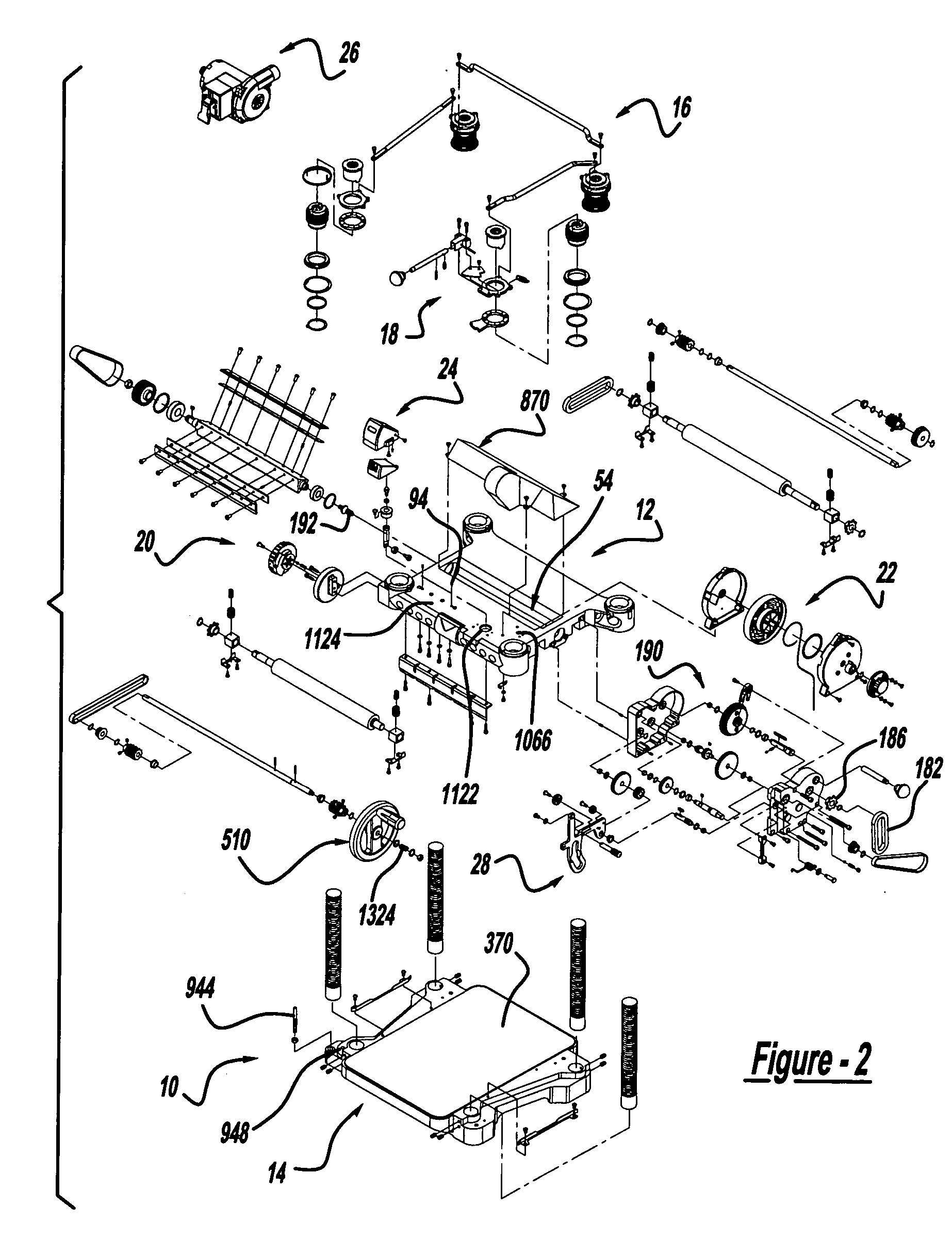

[0057] With reference to FIG. 1 of the drawings, a planer mechanism constructed in accordance with the teachings of the present invention is generally indicated by reference numeral 10. With additional reference to FIG. 2, the planer mechanism 10 is shown to include a planer carriage assembly 12, a base assembly 14, a planer carriage elevation mechanism 16, a planer carriage locking mechanism 18, a carriage height setting mechanism 20, a height scale mechanism 22, a material removal gauge 24, a dust collection system 26 and a power take-off mechanism 28.

[0058] Planer Carriage Assembly

[0059] In FIG. 3, the planer carriage assembly 12 is illustrated to include a carriage 40, a motor assembly 42, a gearbox 44, a first roller assembly 46, a second roller assembly 48 and a cutterhead assembly 50, which will be discussed in more detail below. The carriage 40 is a unitarily formed structure having a cutter pocket 54, two pair of square apertures 58 and a plurality of nut apertures 60, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com