High temperature treating method for inflators

a high temperature treatment and inflator technology, applied in heat treatment apparatus, combustion types, furnaces, etc., can solve the problems of harmful substances, inability to apply a standardized treatment method to inflators, and danger to the body of workers, so as to promote the recovery and reuse of useful materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

(1) Embodiment 1

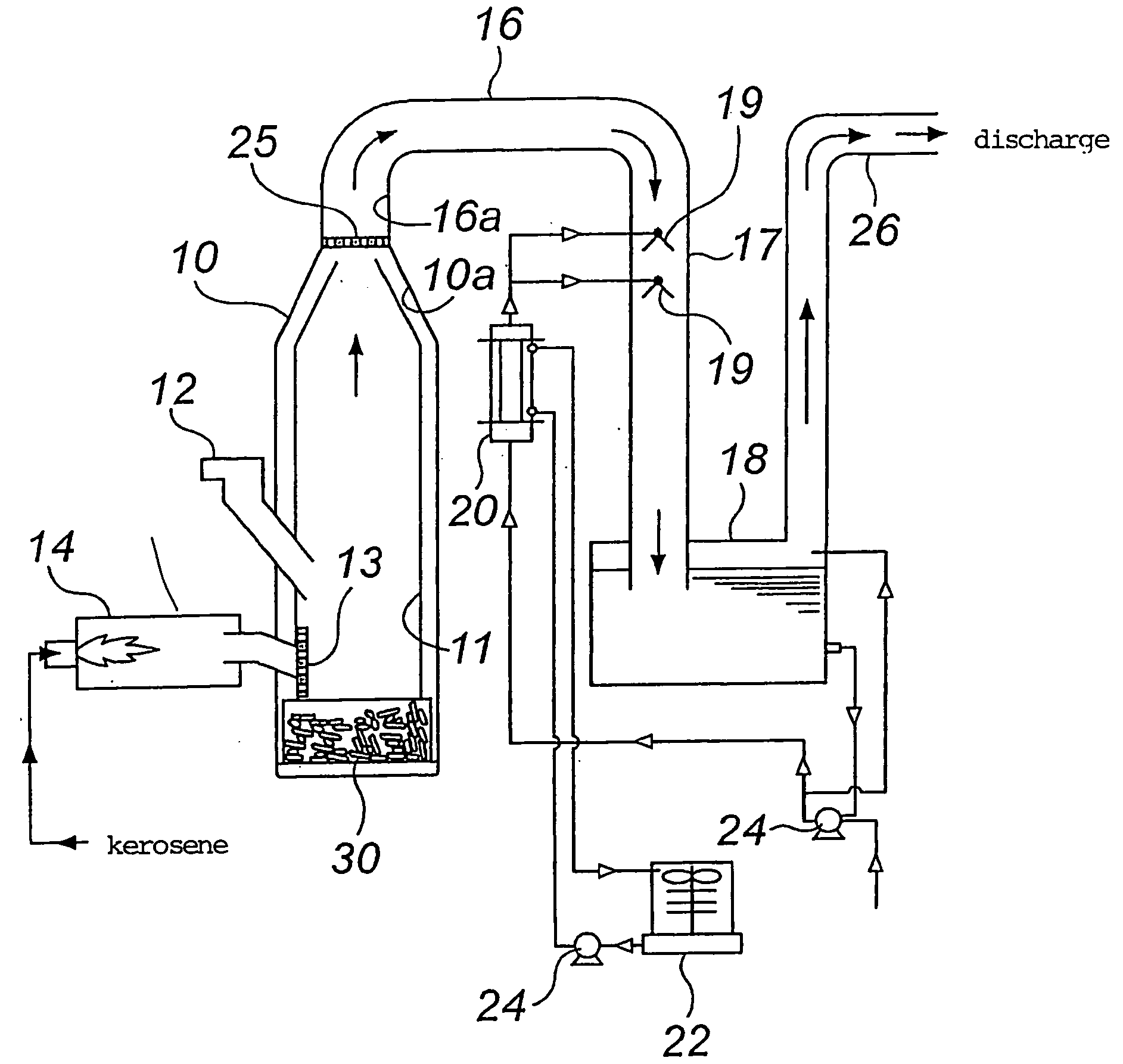

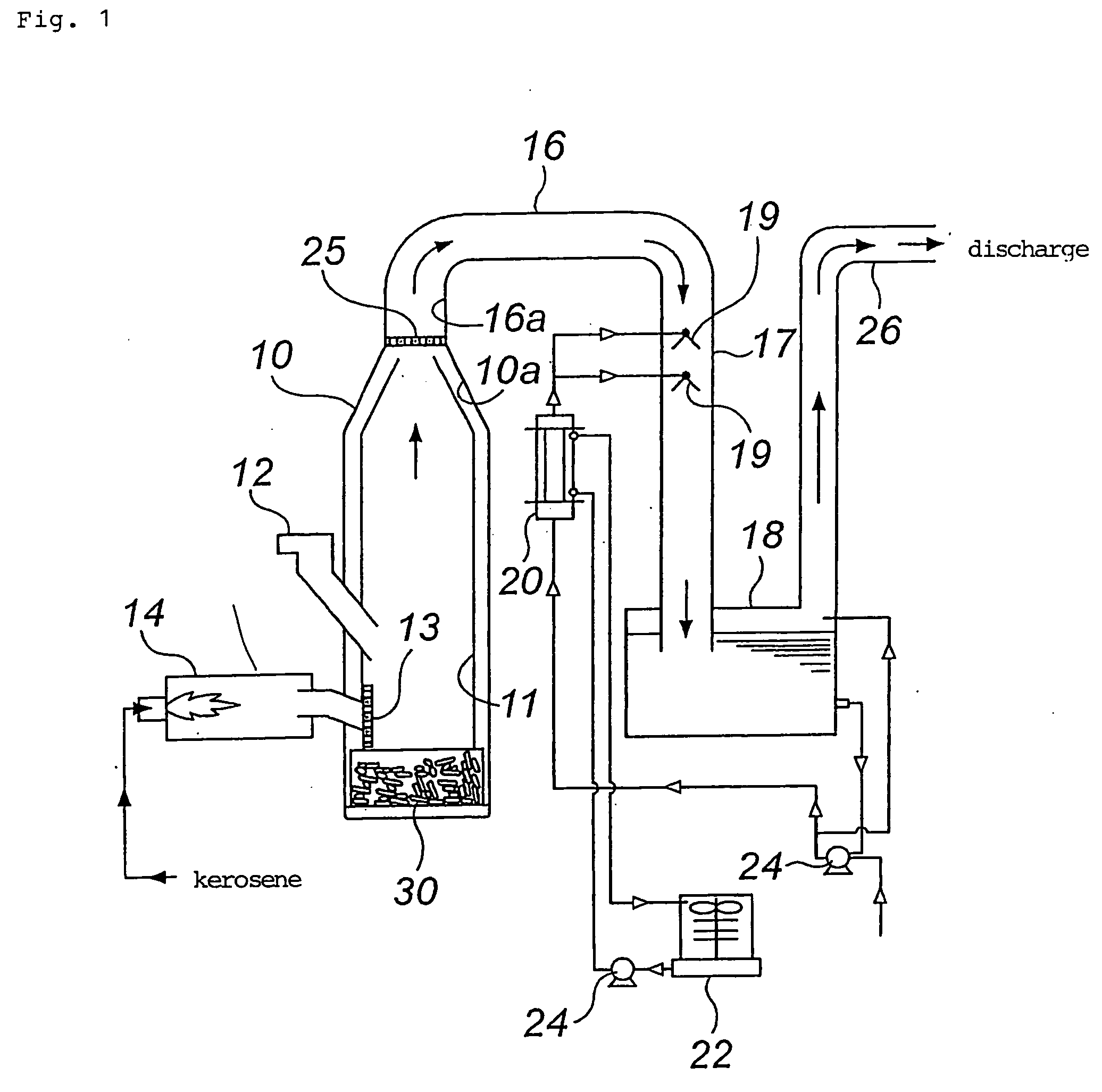

[0023] A high temperature treating method of the present invention will be explained for each of steps below. However, as long as the object of the present invention can be achieved, the respective steps can be properly changed in the order thereof, an ordinary modification conducted by those skilled in the art can be applied to the steps. Accordingly, symbols attached to respective steps are for convenience of explanation and they are not limited to the order of the steps.

(A) Step

[0024] A treatment in a step of cutting and removing wire harnesses connected for inflator activation is performed. The treatment in (A) step is conducted before (E) step of conducting heating treatment.

[0025] Inflators for an air bag which are treatment subjects in the present invention include failure products produced in the manufacturing process as described above and the like, and these inflators include ones with various shapes, sizes and materials mixedly, but all the inflators a...

embodiment 2

(2) Embodiment 2

[0053] A metal recovering method of the present invention will be explained below for each step. The metal recovering method is a treatment method for inflators, which is conducted subsequent to the high temperature treating method for inflators explained in the Embodiment 1.

(F) Step

[0054] After the treatments in (A) to (E) steps according to the high temperature treating method for inflators are terminated, a treatment in a step of cooling the interior of the thermally treating tower 10 to take out the inflators 30 and cutting the inflators 30 taken out is conducted.

[0055] As the inflators, there are ones whose outer shell containers have an apparently sealed structure (which is not a completely sealed structure and has a nearly sealed structure where a clearance(s) is fine) or ones which have a structure in which water is easily entered and stayed. Especially, when the inflators are considered in view of materials thereof, in inflators where a main metal consti...

example 1

(A), (B) Steps

[0063] Wire harnesses connected to igniters of respective inflators were removed. Incidentally, when wire harnesses were connected directly to inflators, the wire harnesses were cut from roots thereof by snips or a nipper, and when wire harnesses were connected to inflators via connectors, the connectors were pulled out by a pulling-off jig. Further, plastic parts equipped in the inflators were removed simultaneously therewith.

(C), (D) Steps

[0064] Recovered inflators were grouped according to respective main metals constituting outer shell containers (aluminum, iron and stainless steel) and shapes thereof.

(E) Step

[0065] A high temperature treatment was conducted on inflators for a driver's side (having a disk shape, a diameter of about 70 mm and a thickness of about 28 mm; a housing is made of stainless steel having a melting point of 1450 to 1650° C.; an amount of a gas generating material is 40 g and an ignition temperature thereof is 223° C.) of the inflator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com