Positive active material for rechargeable lithium battery and method of preparing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

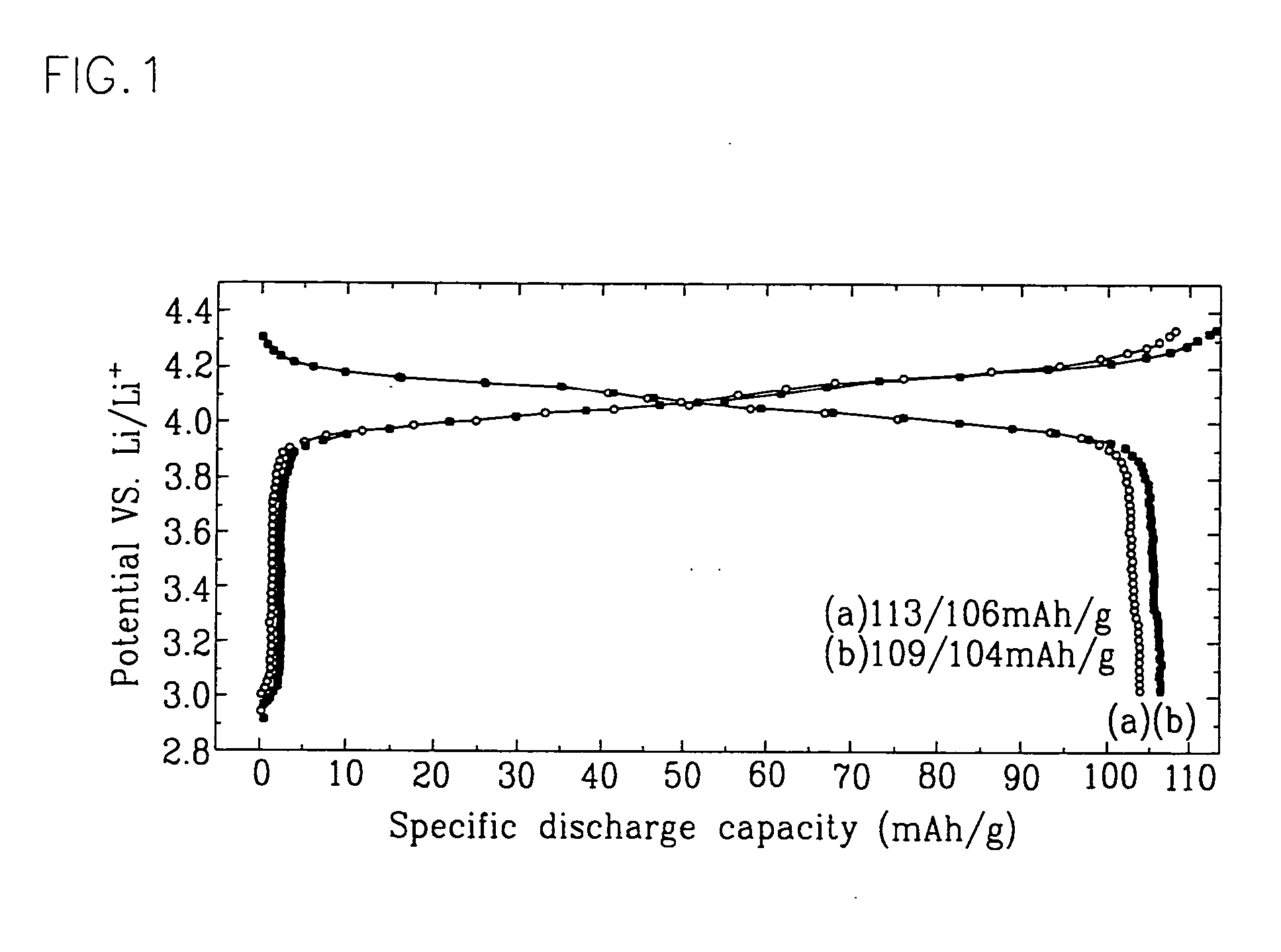

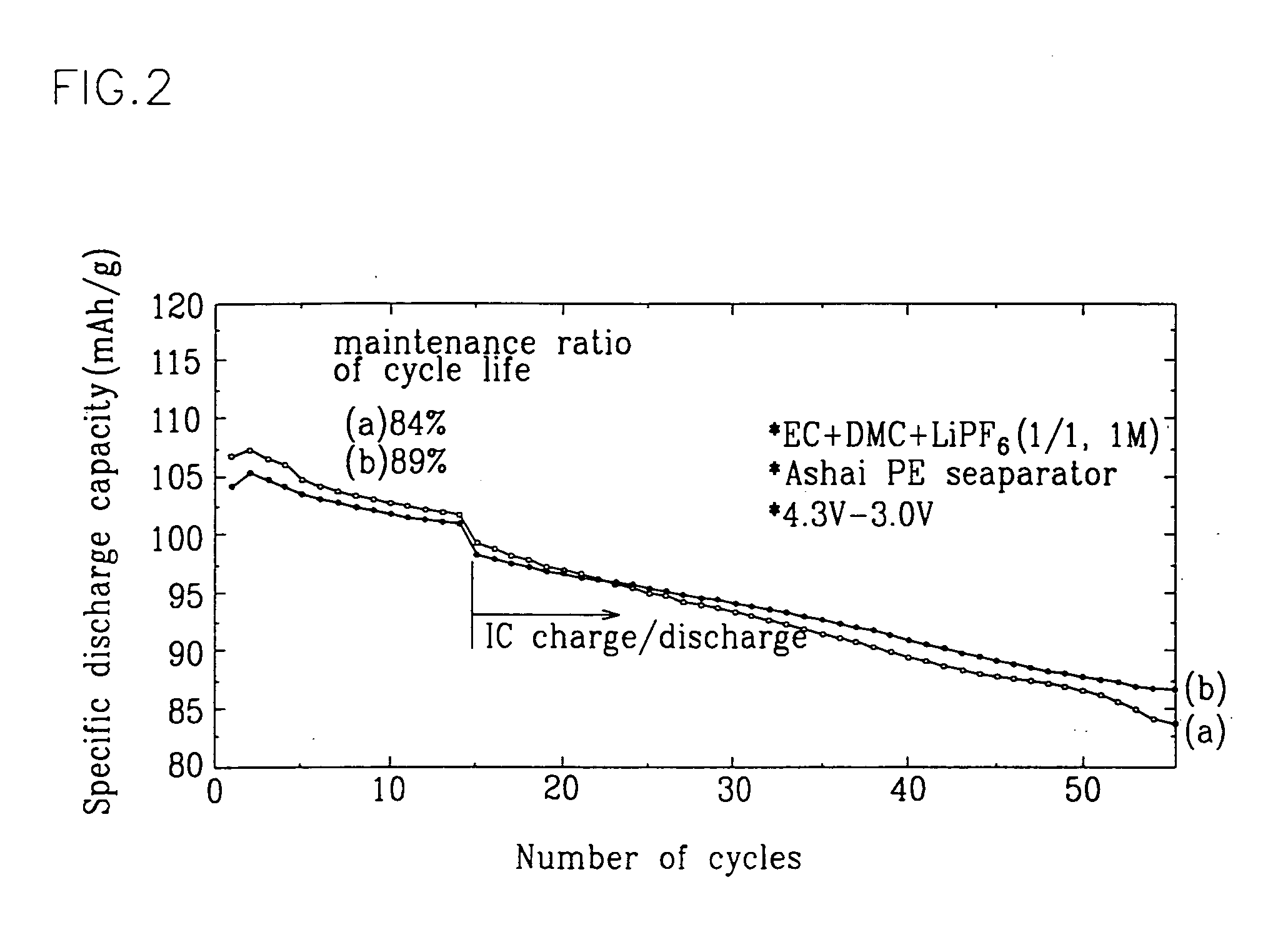

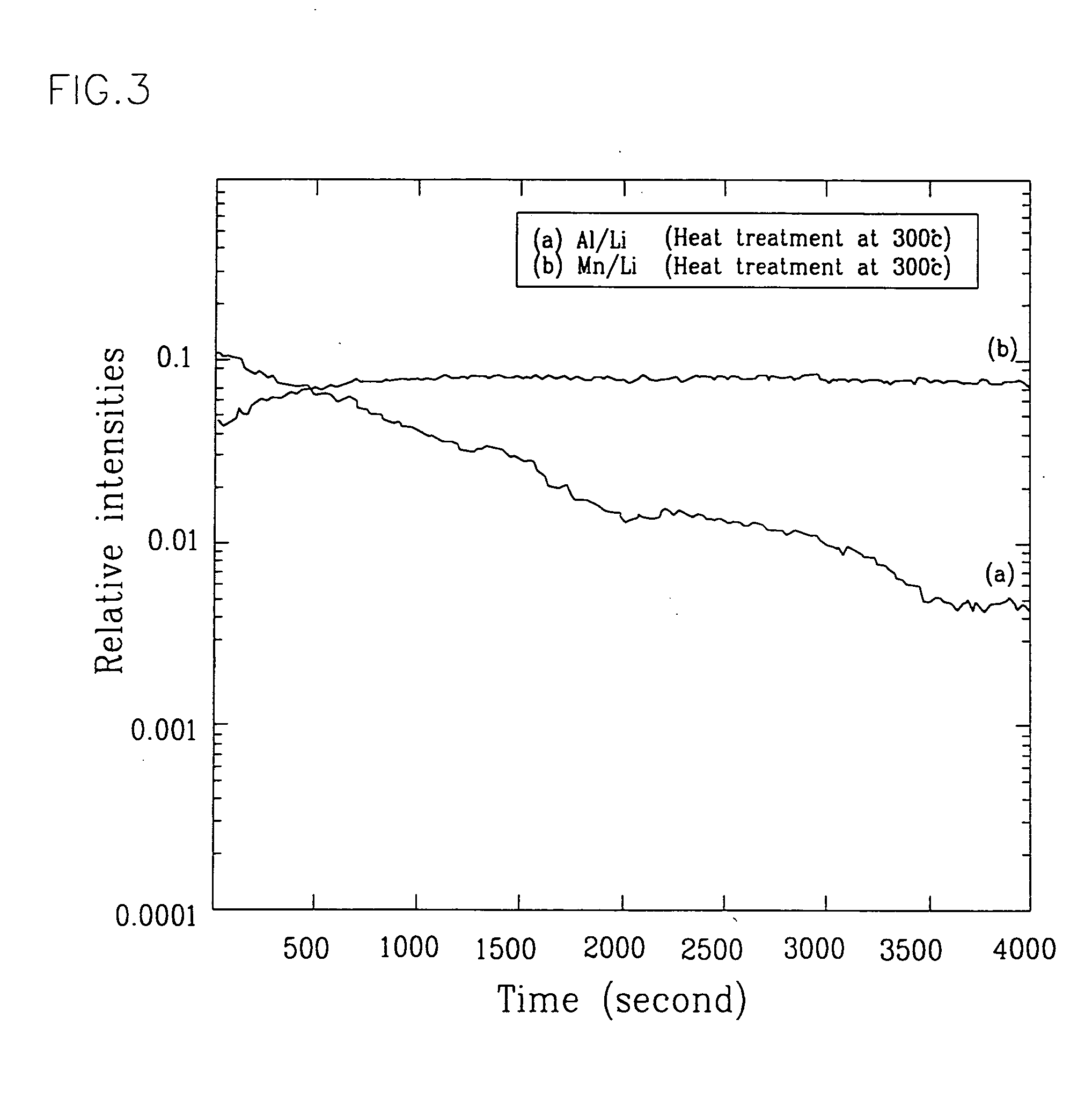

[0018] An aluminum isopropoxide solution having a 5 weight-percent concentration was prepared by refluxing an aluminum isopropoxide powder in ethanol at about 100° C. for about half an hour. The aluminum isopropoxide solution was then mixed with a powder of LixMn2-yAlyO4-zFz where 06 for a solute.

example 2

[0019] The positive electrode preparing procedure was performed in the same way as in Example 1 with the exception that the heat-treating temperature was heightened up to 900° C. A coin-type half cell was fabricated with the resulting positive electrode in combination with other components as described in Example 1.

example 3

[0020] An aluminum isopropoxide solution having a 5 weight-percent concentration was prepared by refluxing an aluminum isopropoxide powder in ethanol at about 100° C. for about half an hour. The aluminum isopropoxide solution was then mixed with a powder of LixMn2O4 where 0<x≦1.5 at an identical volume ratio in a moisture free dry room such that an overall surface of the power became wet sufficiently by the solution, and dried in the same room. Thereafter, the mixture was heat-treated at about 300° C. for about 10 hours under a dry air atmosphere to thereby prepare a metallic oxide-coated active material. The subsequent positive electrode processing steps were performed in the same way as in Example 1. A coin-type half cell was fabricated with the resulting positive electrode in combination with other components as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com