Level measurement for grease separators

a technology for level measurement and grease separators, which is applied in the direction of liquid displacement, separation process, instruments, etc., can solve the problems of not all manual interceptors are constructed of metal, not all are compatible with level measurement systems, and it is not practicable to design a custom level measurement system for each tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

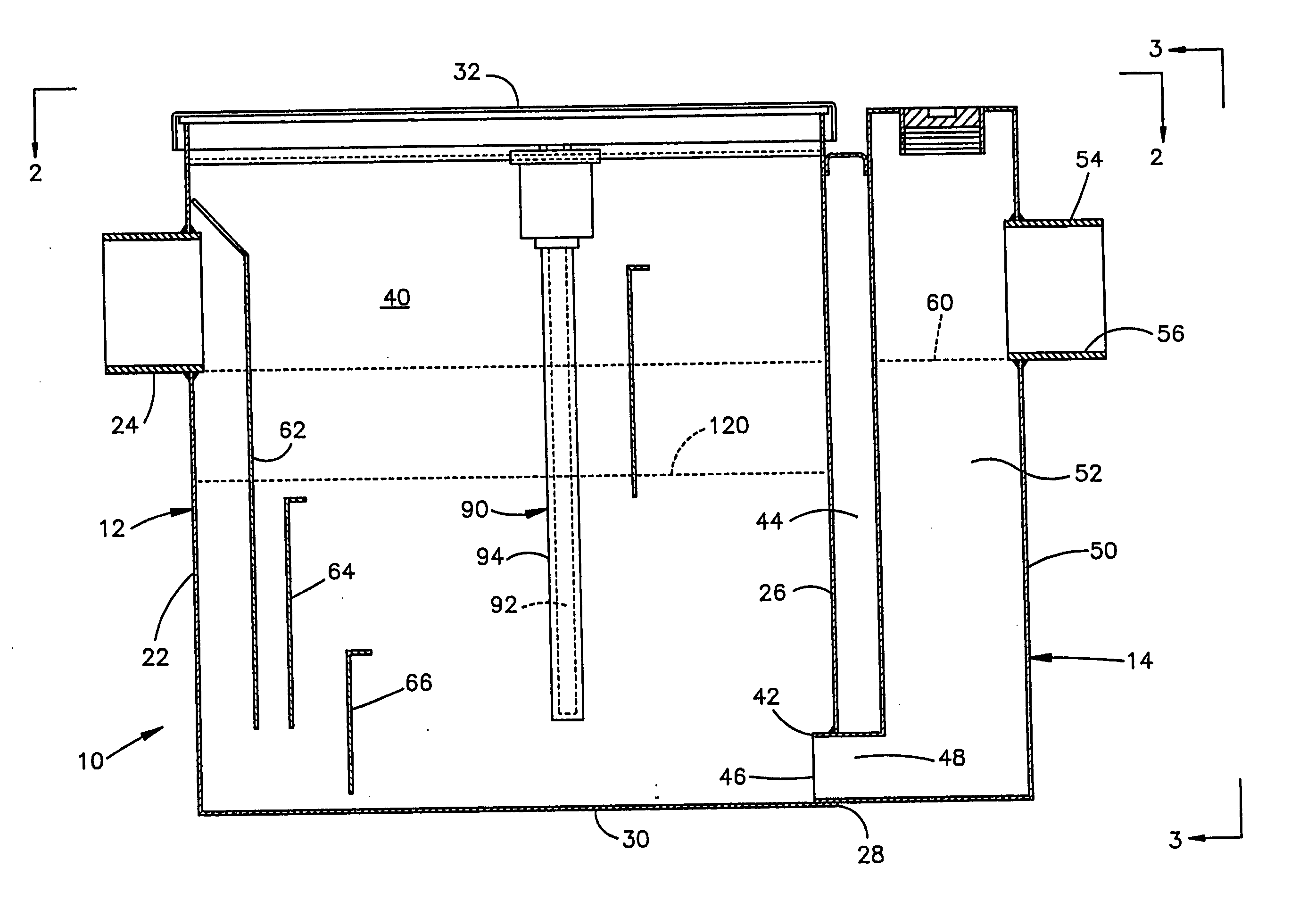

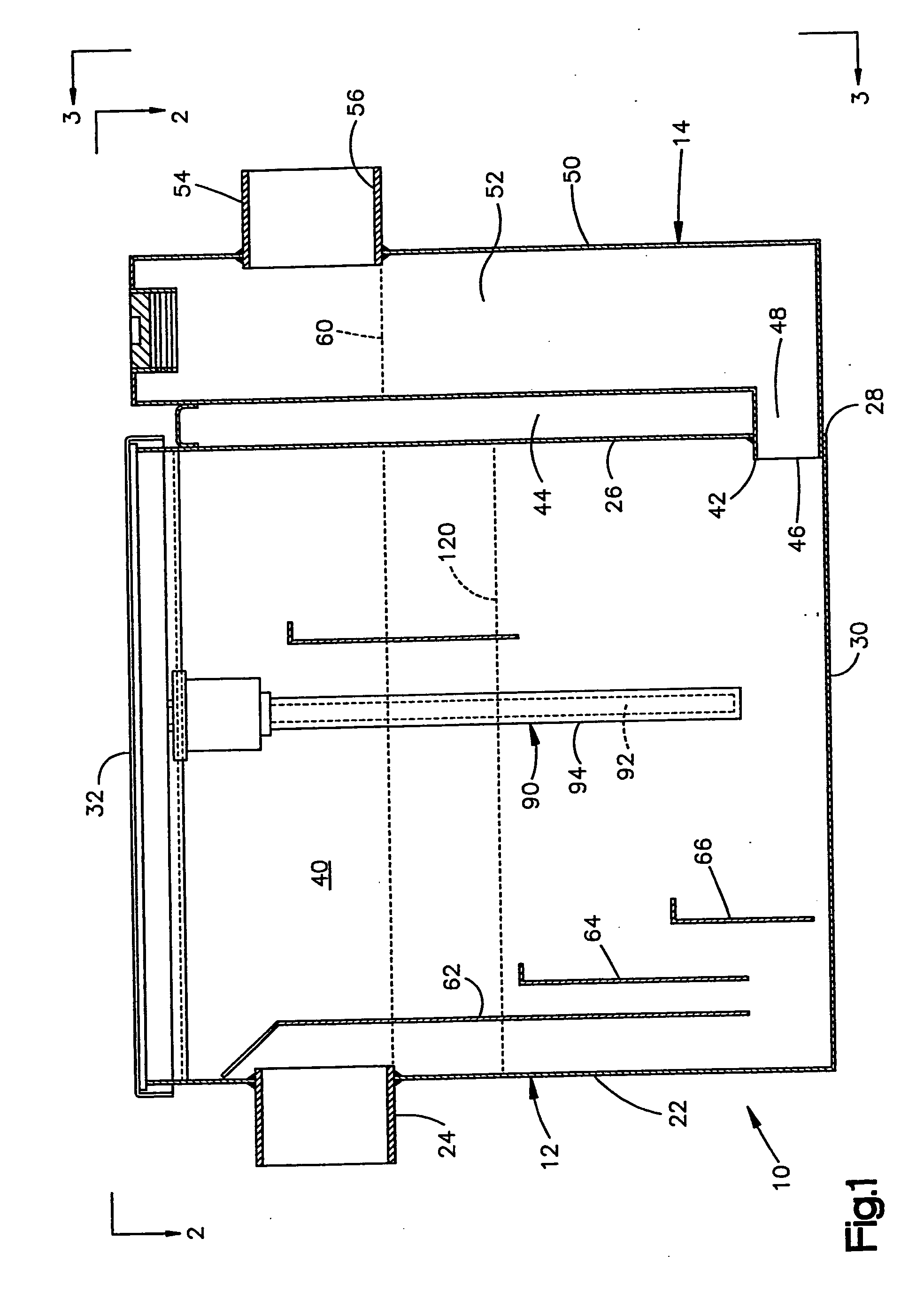

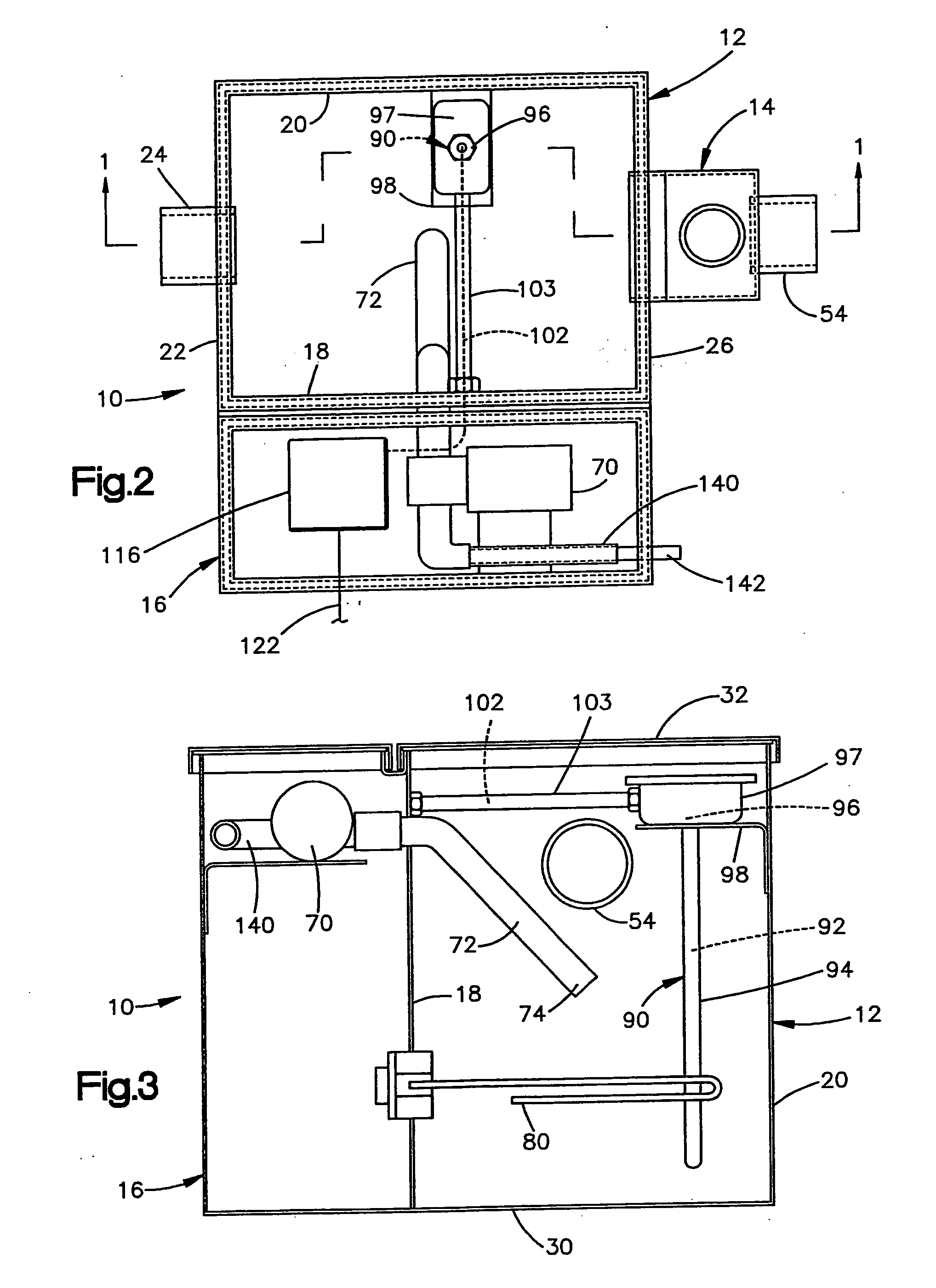

[0022] The present invention relates to apparatus for separating grease from effluent containing grease and water. The present invention is applicable to grease separators (interceptors) of various constructions, as shown and otherwise. As representative of the present invention, FIGS. 1-4 illustrate an interceptor 10 in accordance with a first embodiment of the invention. The interceptor 10 includes a separation tank 12 and a trap leg 14. An equipment cabinet 16 is connected to the separation tank 12.

[0023] The separation tank 12 is made from an electrically conductive material, such as metal, and includes a front wall 18 (FIG. 2) and an opposite back wall 20. An inlet wall 22 interconnects the front and back walls 18 and 20. An inlet 24 extends through the inlet wall 22. At its opposite end the separation tank 12 includes an end wall 26 (FIG. 2). The end wall 26 has a rectangular opening 28 into the trap leg 14.

[0024] The separation tank 12 also has a bottom wall 30 and a remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Lifetime stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com