Electrochemical cell cooling system

a technology of electrochemical cells and cooling systems, applied in the field of electrochemical cell cooling systems, can solve the problems of venturi inducing a negative pressure condition in the container and loop, and achieve the effect of efficient and cost-effective cooling and simple and efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

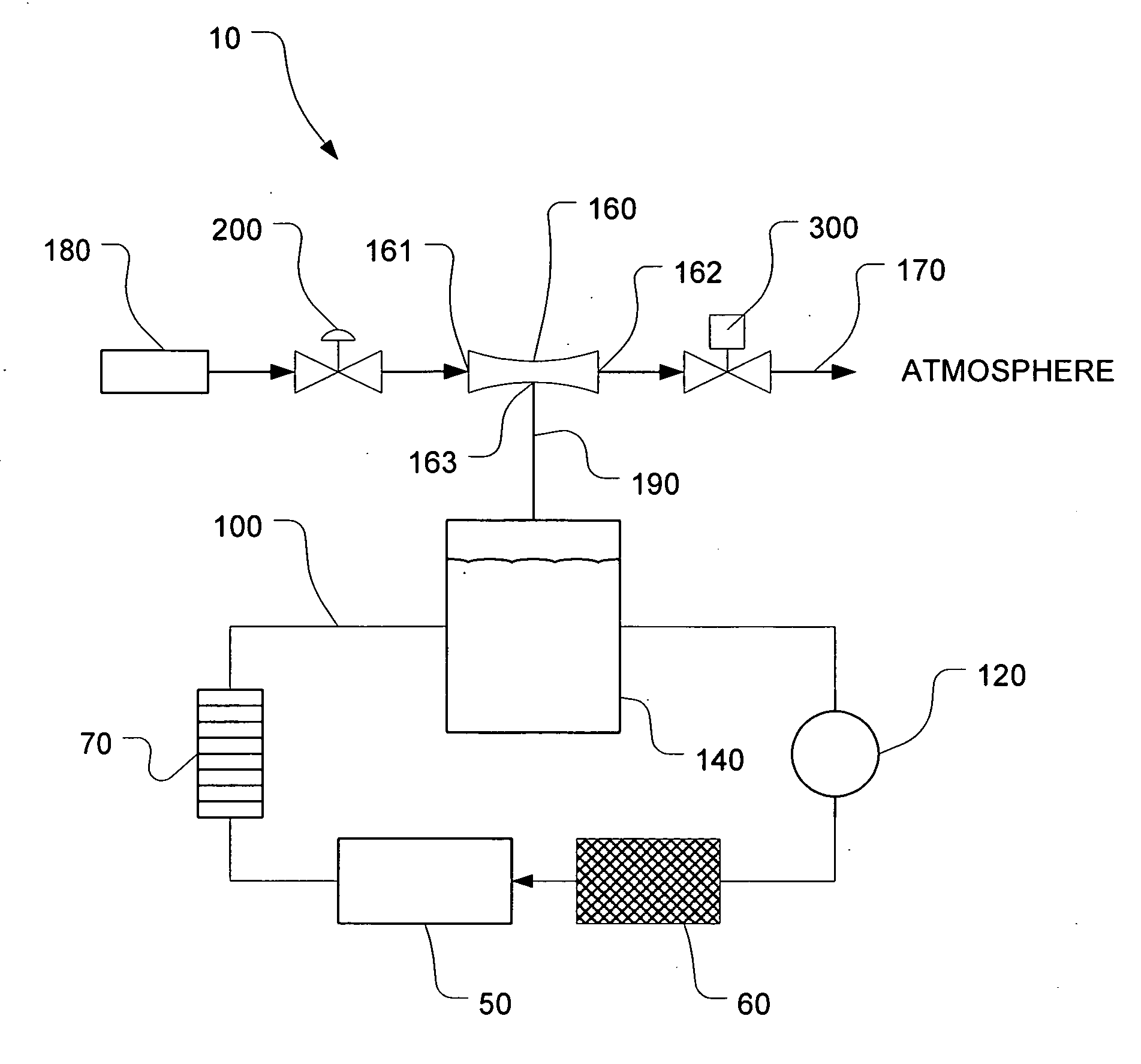

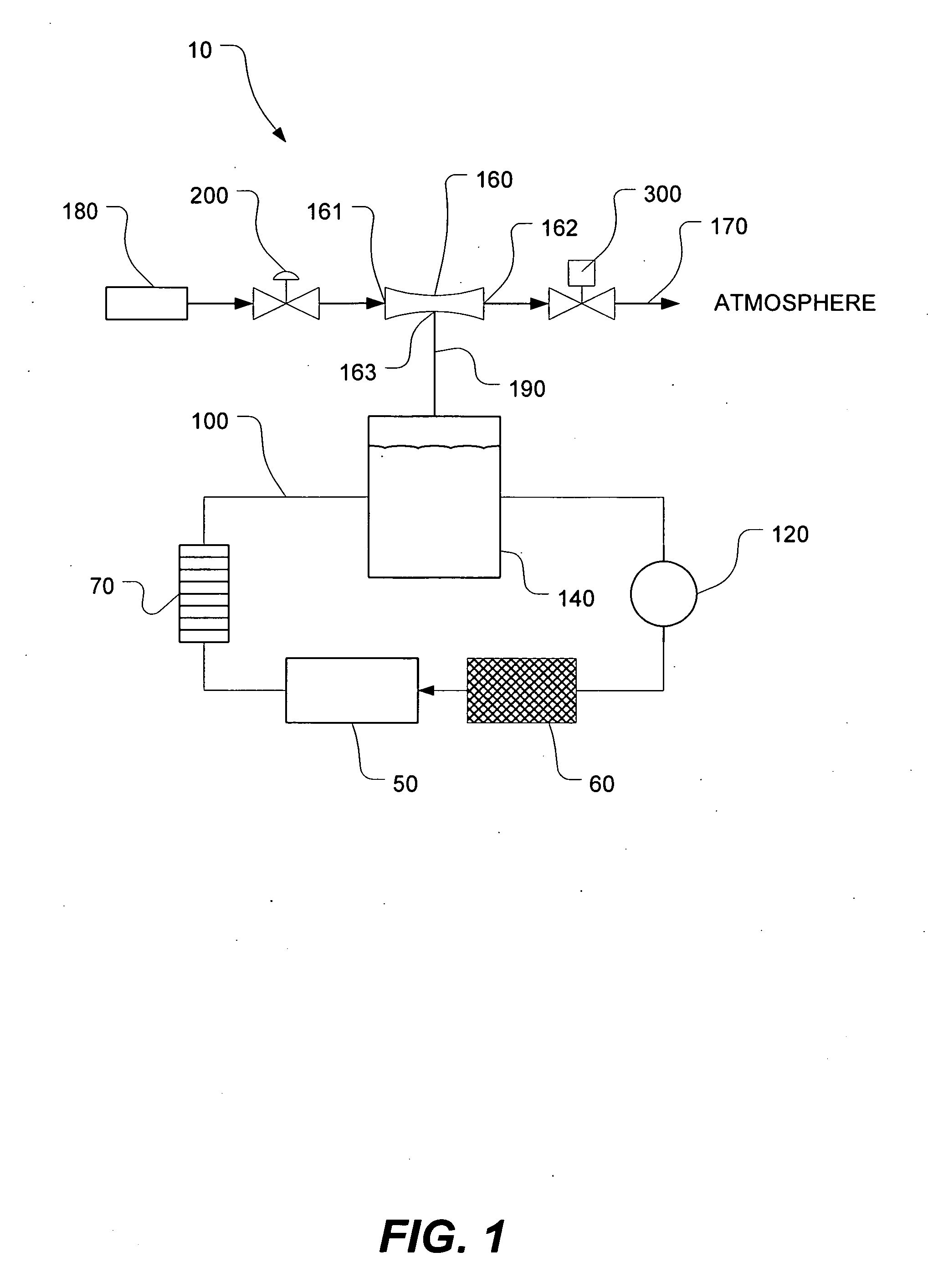

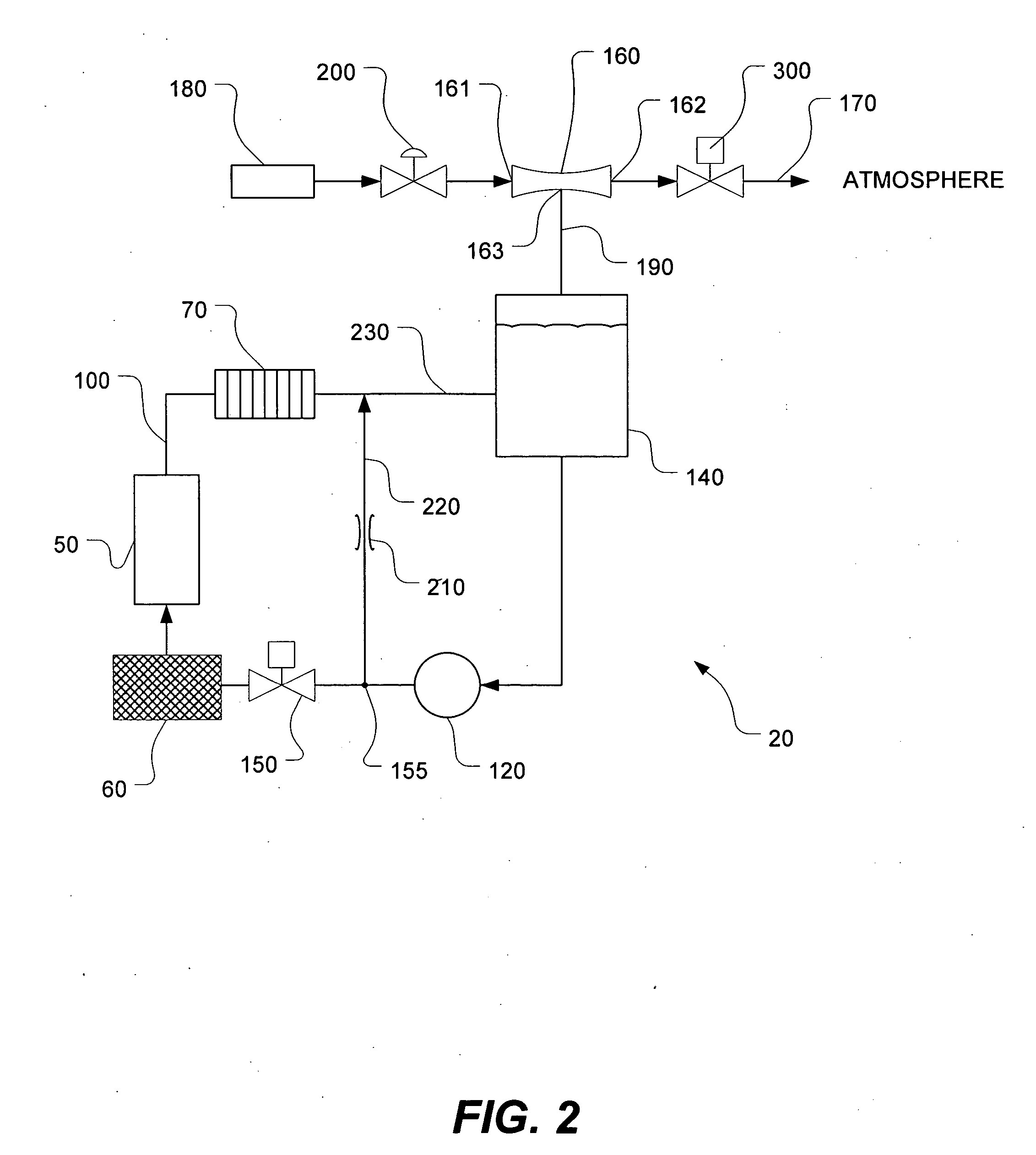

[0024]FIG. 1 shows, in schematic form, an electrochemical cell cooling system, generally designated by reference numeral 10, in accordance with a first embodiment of the present invention. Although the present invention can be used to efficiently cool fuel cell systems, it is not limited to application in fuel cell systems. Rather, it is applicable to any electrochemical cell system where liquid coolant is needed to control the operating temperature of the electrochemical cell.

[0025] As shown in FIG. 1, the cooling system 10 includes a coolant circulation loop 100 for circulating a coolant through or past an electrochemical cell 50 for absorbing heat from the exothermic reaction of a working electrochemical cell 50. The coolant circulation loop 100 includes a coolant container 140, which is also known as an overflow tank or storage tank. The coolant container 140 stores an excess volume of coolant at a nominal operating pressure, which can be adjusted in a manner to be described be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com