Elongated element for the frame of a panel system comprising a flexible sheet material

a flexible sheet material and frame technology, applied in the field of frames, can solve the problems of difficult to ensure the effect of mutuality, frame cannot be used to stretch a sheet material, and the frame of this document is not much fit to be used with sheet materials of large size, etc., and achieve the effect of convenient fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

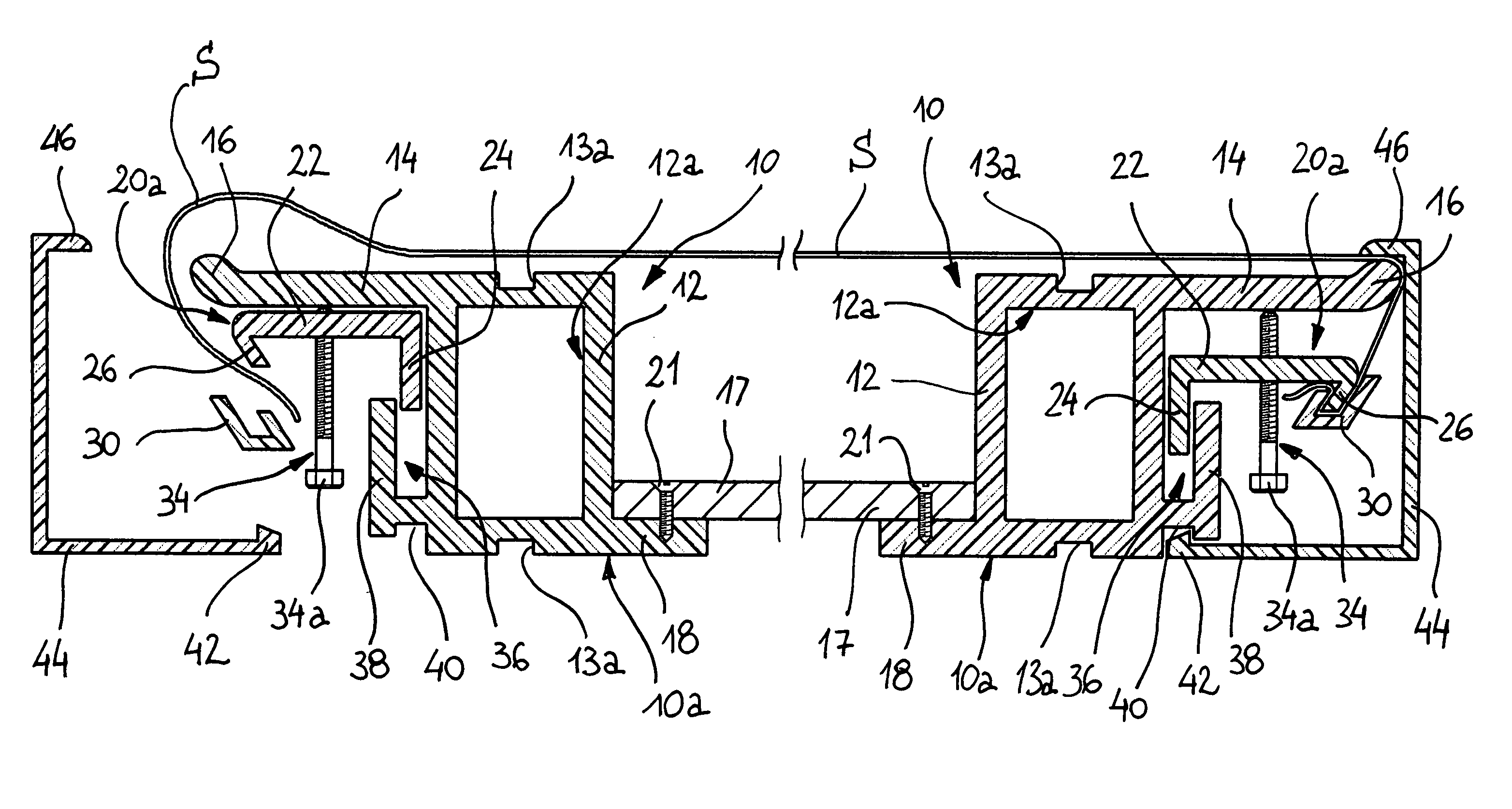

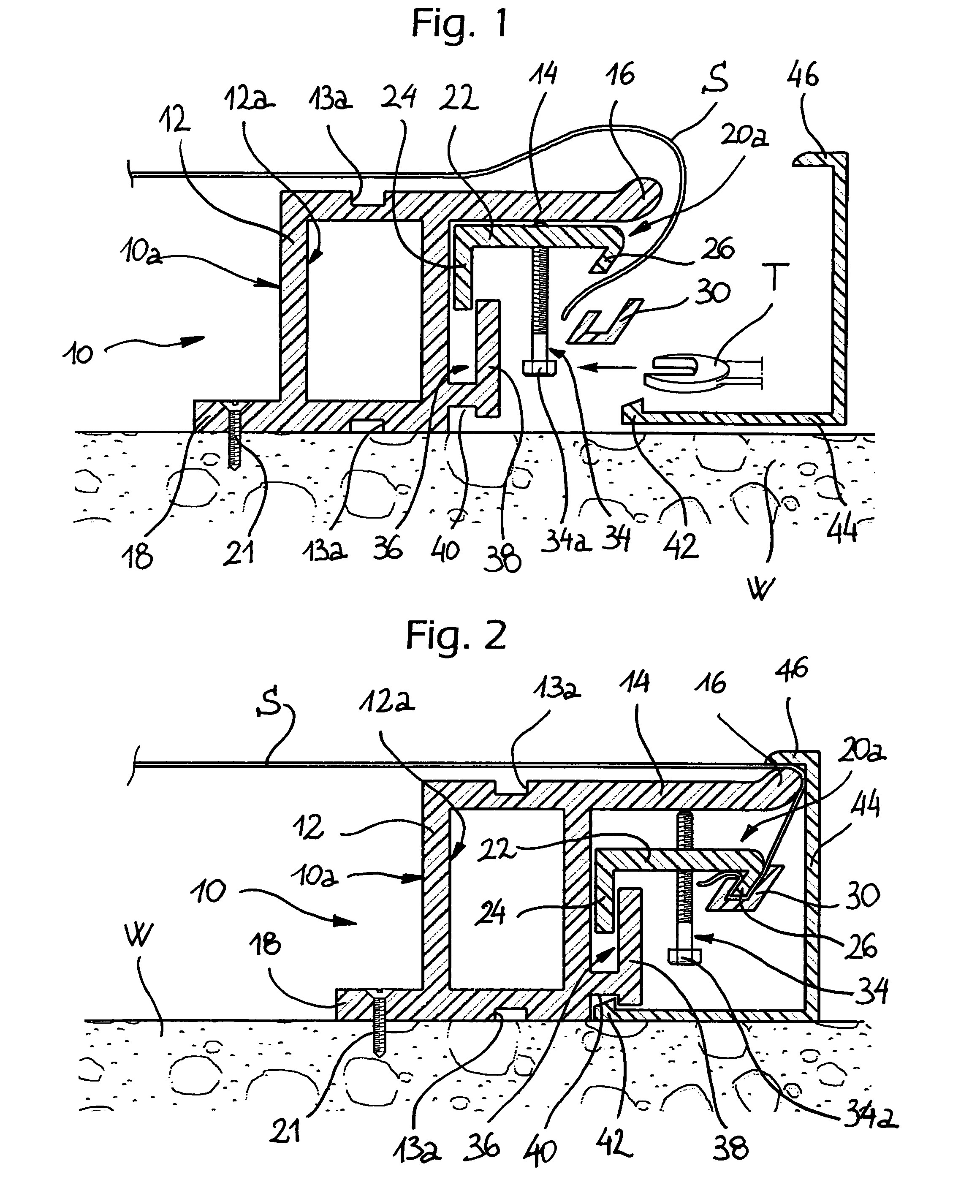

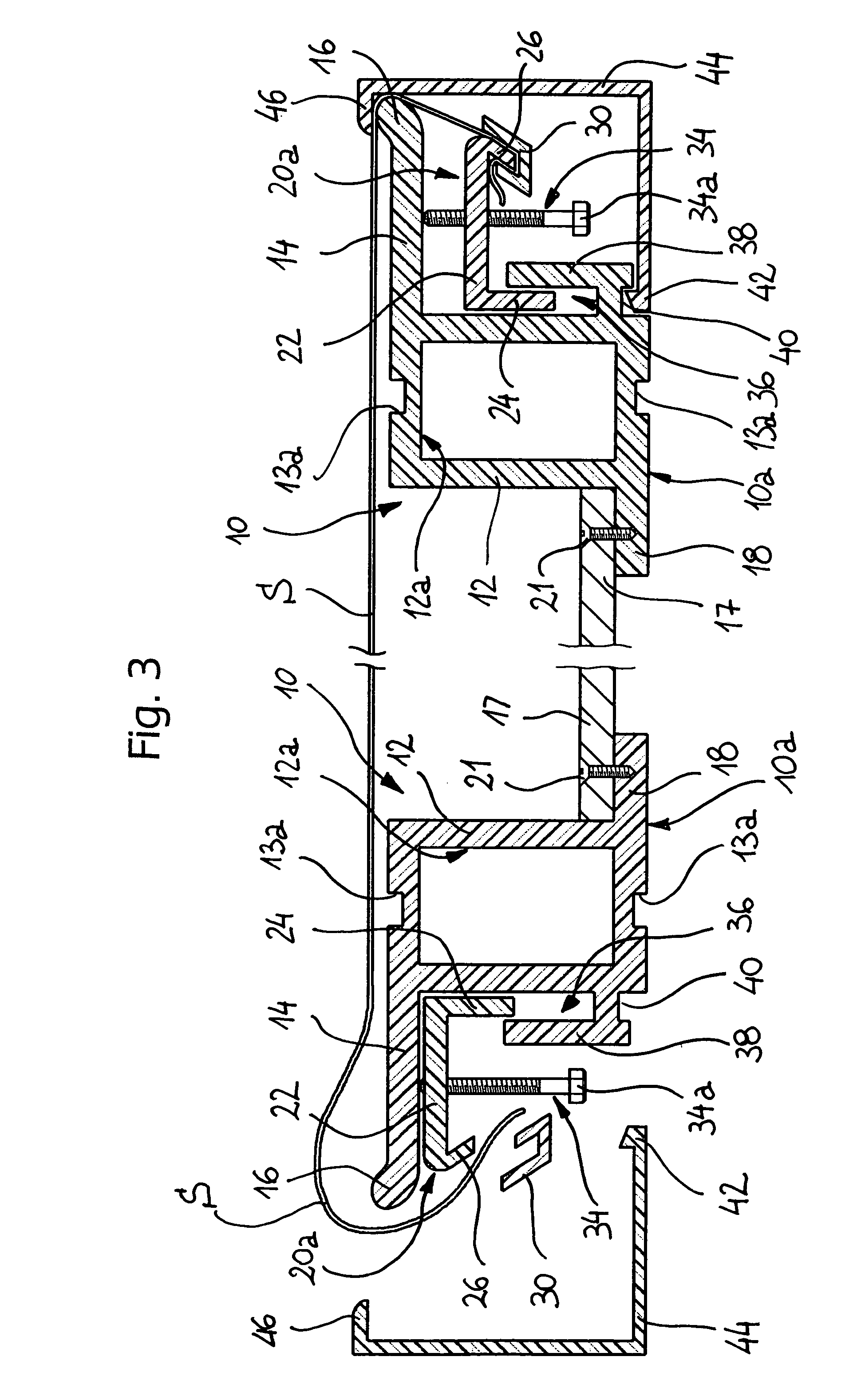

[0030] With initial reference to FIGS. 1 to 6, an elongated element according to a first embodiment of the invention is indicated 10 as a whole.

[0031] Each element 10 comprises a main profile 10a which includes a beam portion 12 having preferably an axial cavity 12a, and from which an elongated laminar appendage 14 extends, which is provided with a free winding end 16 having a rounded shape. The profile 10a is advantageously made in a single piece of plastic or composite material, or of a metal such as aluminium, preferably obtained as a result of an extrusion forming process.

[0032] Conveniently, the beam portion 12 has a polygonal section, for example rectangular, the appendage 14 being the prolongation of one of the sides of the portion 12. A connection portion adapted to allow the profile 10a to be fixed to a support surface, is associated to the beam portion 12. This connection portion may have whatever shape depending on the specific connection requirement, and it may consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com