Magnetic memory storage device

a magnetic memory and high density technology, applied in special recording techniques, instruments, nanoinformatics, etc., can solve the problems of asymmetry in the switching characteristics of bits, potential reduction of ar/r magnetoresistance resulting from angular displacement, reference layer to become unpinned and lose its set orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Before proceeding with the detailed description, it is to be appreciated that the present invention is not limited to use or application with a specific type of magnetic memory. Thus, although the present invention is, for the convenience of explanation, depicted described with respect to typical exemplary embodiments, it will be appreciated that this invention may be applied with other types of magnetic memory.

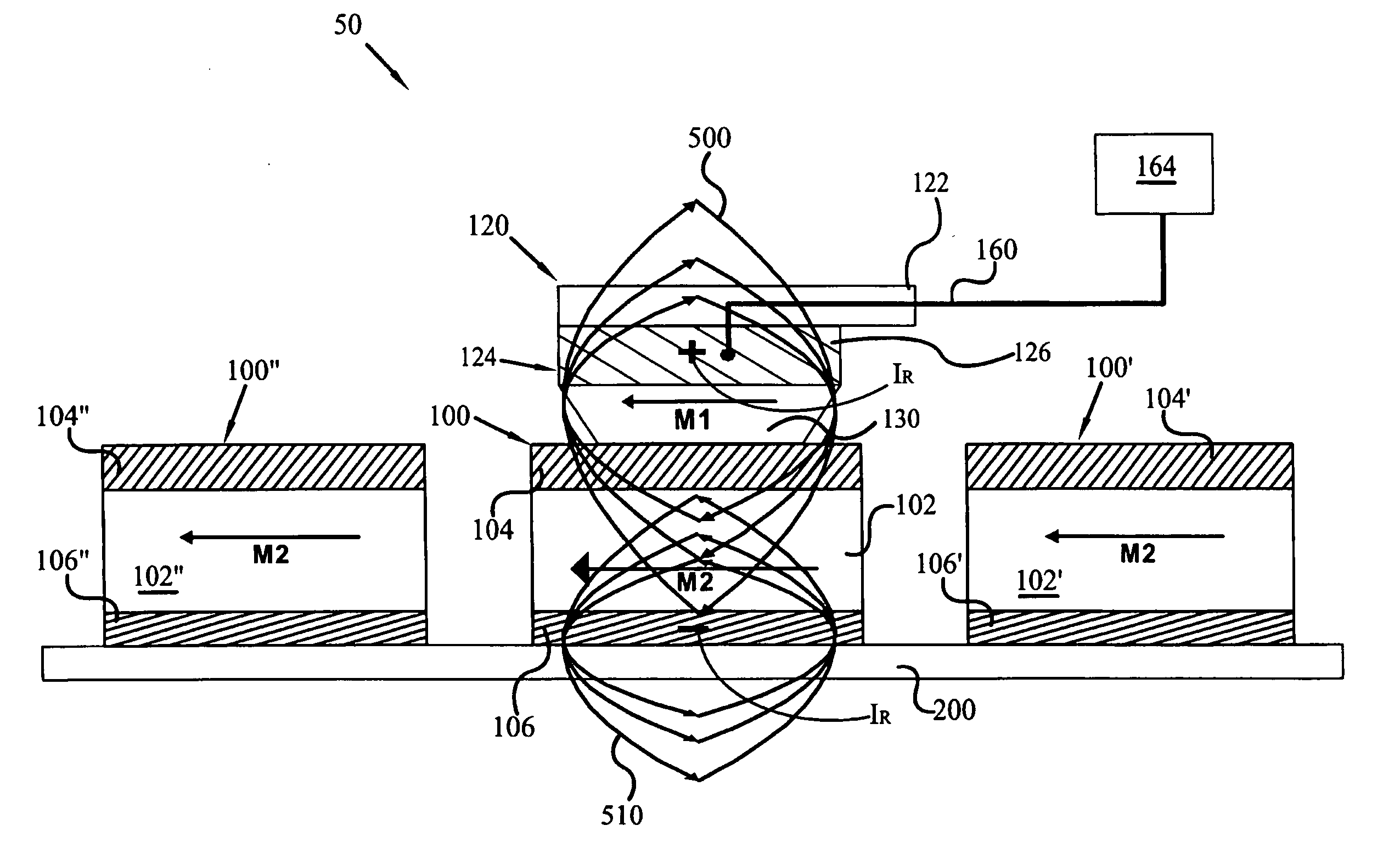

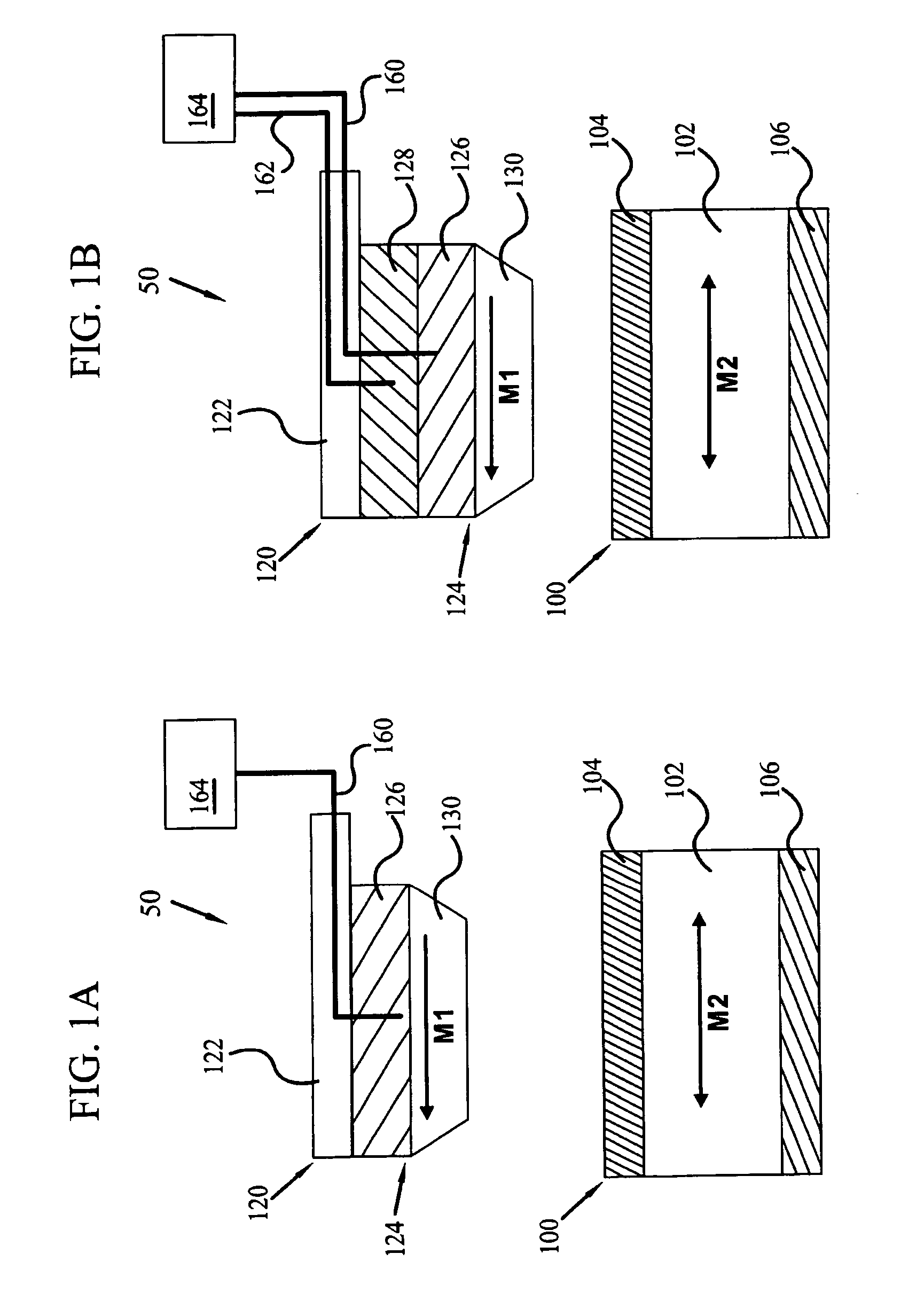

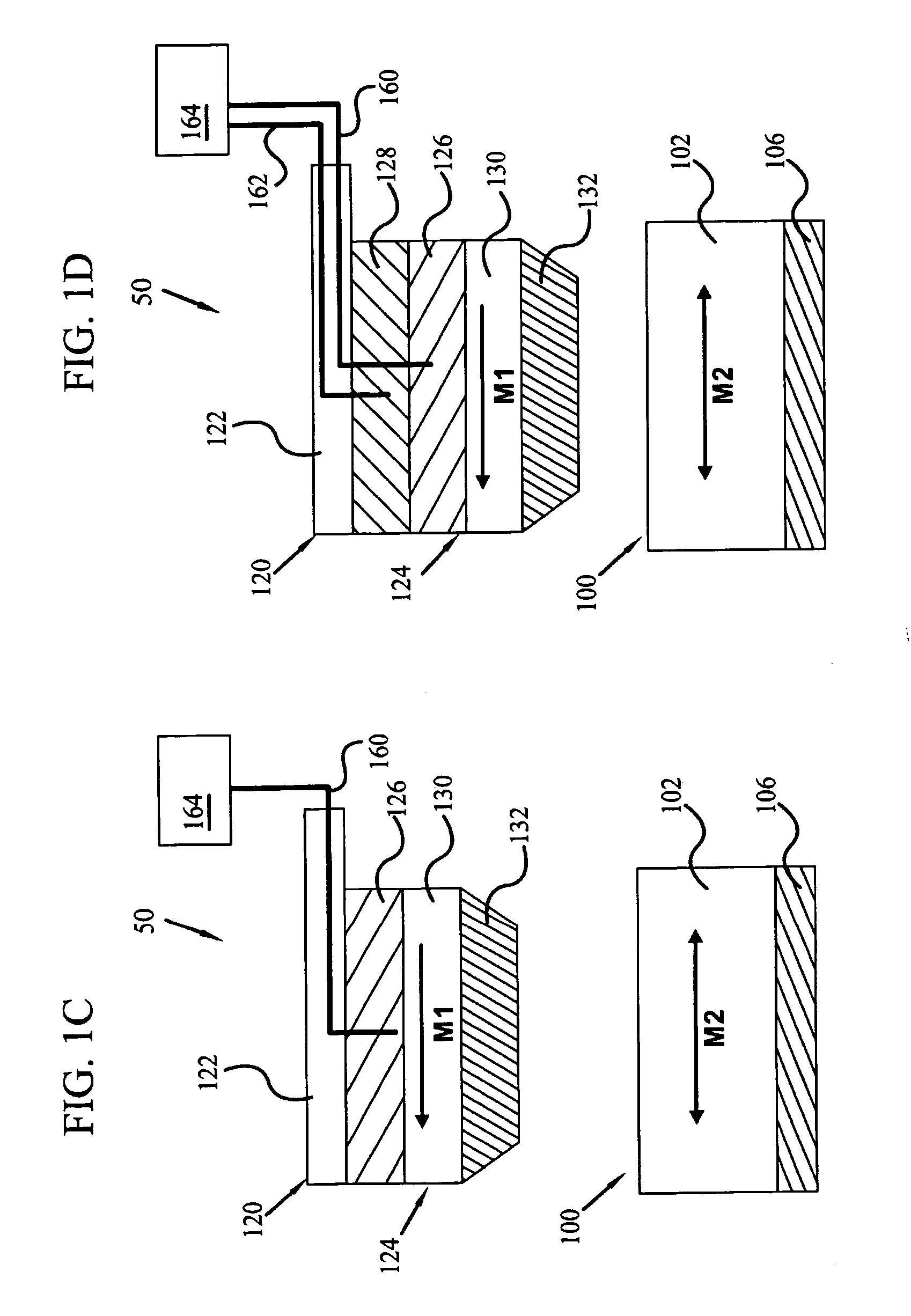

[0033] Referring now to the drawings, and more particularly to FIGS. 1A and 1B, there is shown a portion of a nanotip based magnetic memory with thermally assisted switching 50, having at least one magnetic memory cell 100 and movable probe 120 positioned proximate to the memory cell 100, according to an embodiment of the present invention. In at least one embodiment, the magnetic memory cell 100 may be a divided magnetic tunnel junction memory cell. Specifically, the magnetic memory cell 100 may have a ferromagnetic data layer 102, a intermediate layer 104 and a cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com