Cutting structure for single roller cone drill bit

a cutting structure and drill bit technology, applied in drill bits, cutting machines, earthwork drilling and mining, etc., can solve the problems of more and less wear on the cutting element on the single cone bi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

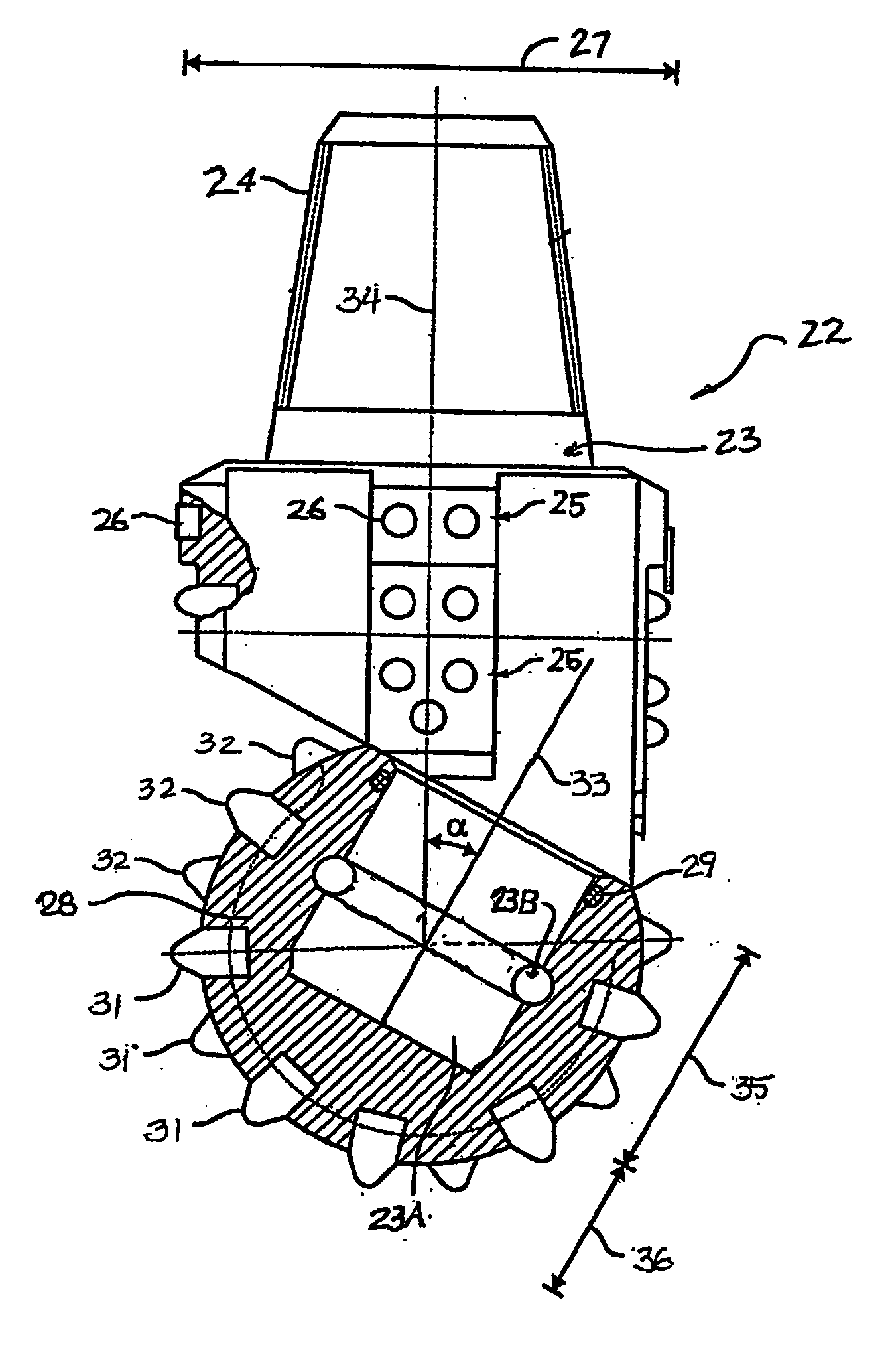

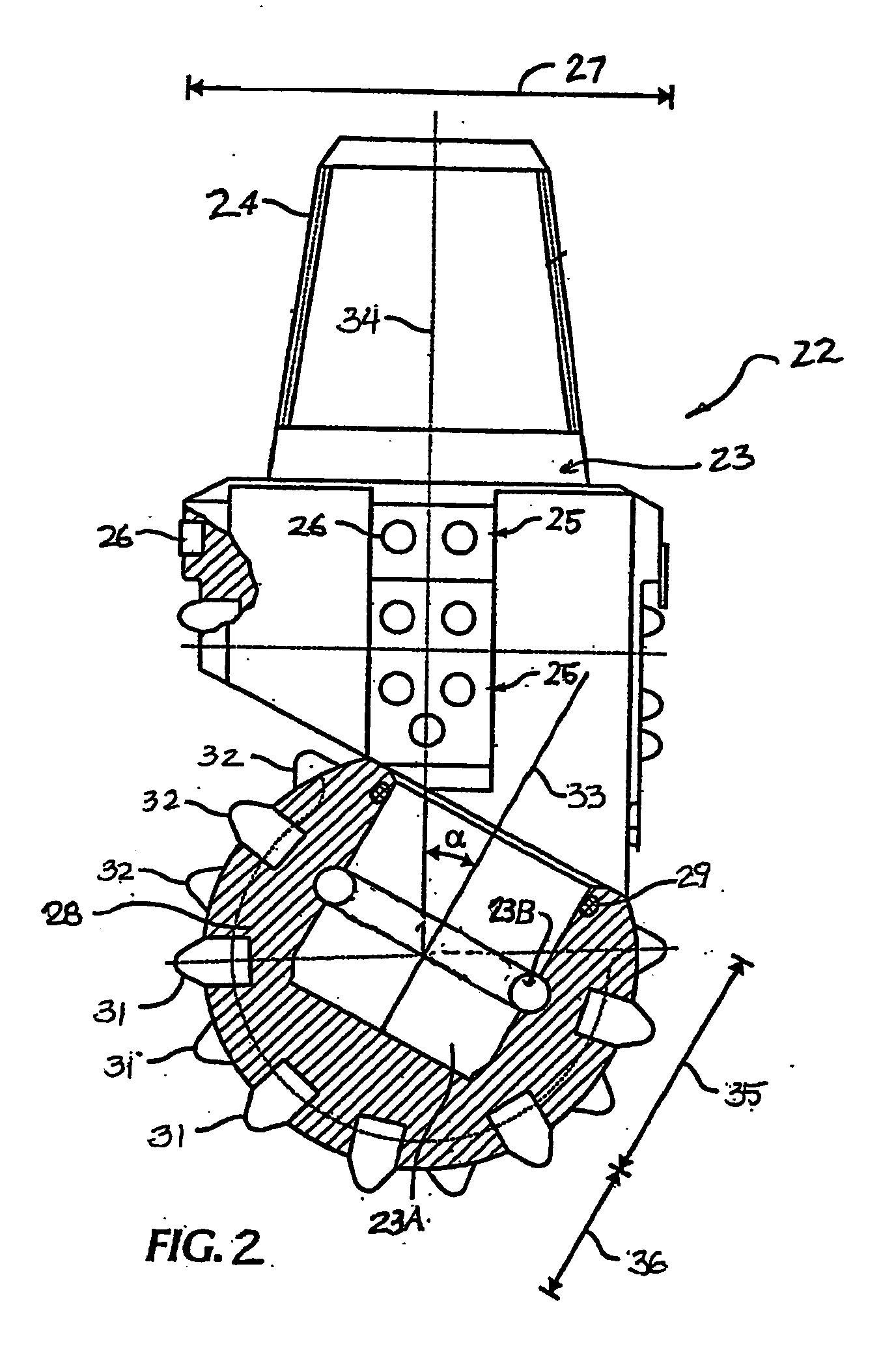

[0025] A general structure for a single cone roller cone drill bit which can be made according to various embodiments of the invention is shown in a cut away view in FIG. 2. The bit 22 includes a body 23 made of steel or other high strength material. The body 23 includes a coupling 24 at one end adapted to join the bit body 23 to a drill string (not shown) for rotating the bit 22 during drilling. The bit body 23 may also include gage protection pads 25 at circumferentially spaced apart positions about the bit body 23. The gage protection pads 25 may include gage protection inserts 26 in some embodiments. The gage protection pads 25 if used, extend to a drill diameter 27 of the bit 22.

[0026] Another end of the bit body 23 includes a bearing journal 23A to which a single roller cone 28 is rotatably mounted. In some embodiments, the cone 28 may be locked onto the journal 23A by locking balls 23B disposed in the corresponding grooves on the outer surface of the journal 23A and the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com