Lead free, composite polymer based bullet and cartridge case, and method of manufacturing

a composite polymer and bullet technology, applied in the field of bullets/projectiles, can solve the problems of not providing a specific range of ingredients, and not revealing the use of both nylon materials in the same bullet, and achieve the effect of superior strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention provides a cartridge case body strong enough to withstand gas pressures that equal or surpass the strength of brass cartridge cases under certain conditions. Furthermore, the present invention provides a lead free, composite polymer based bullet having a specific gravity high enough to perform as well as if not better than conventional lead based bullets.

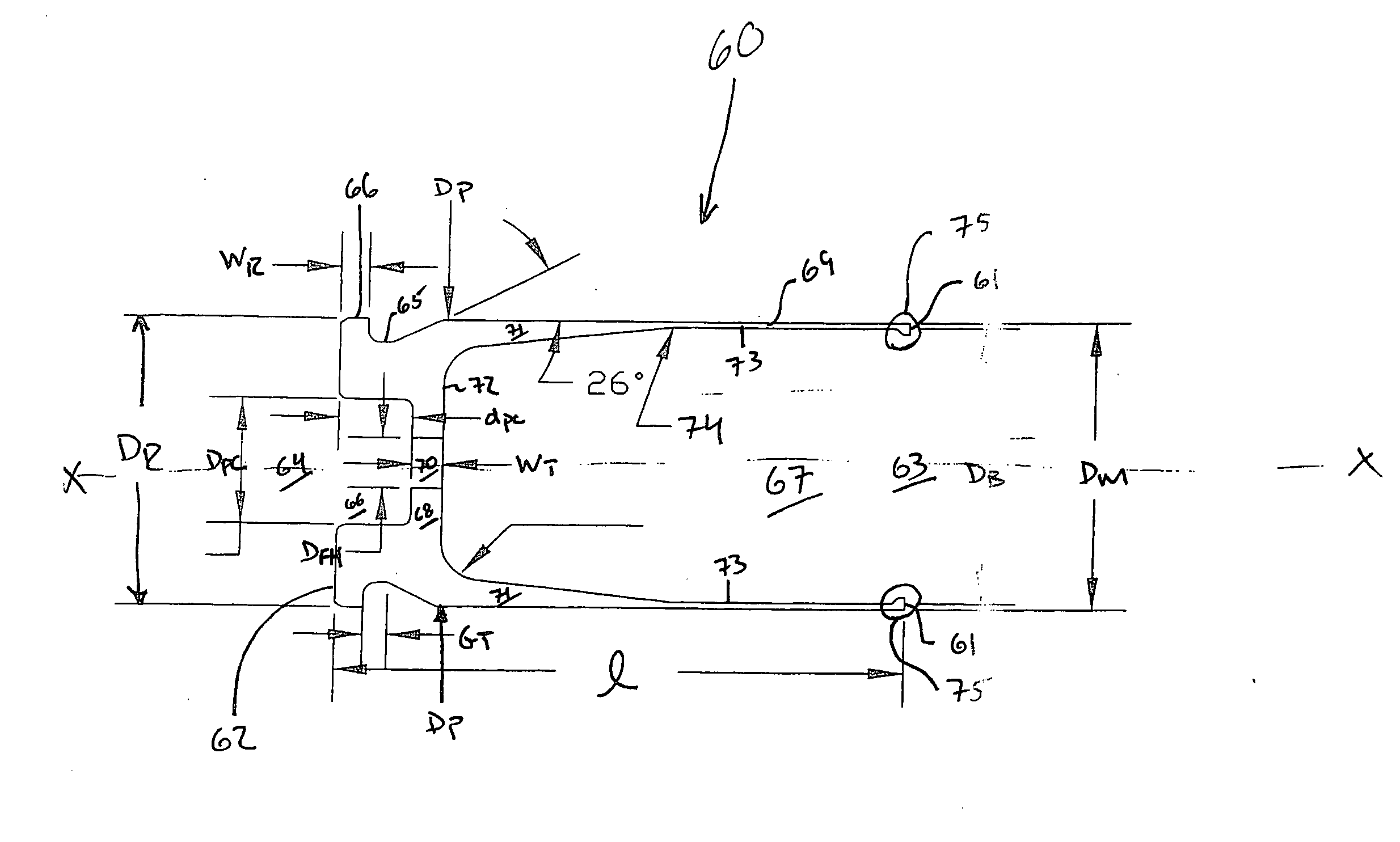

[0055]FIG. 6 illustrates a first embodiment of the invention. In particular, a cartridge case 60 for holding a 0.45 caliber bullet therein is shown. The cartridge case satisfies S.A.A.M.I. requirements for 0.45 caliber ammunition. It is understood to one skilled in the art that the dimensions of the present invention may be adjusted according to ammunition of varying size. Accordingly, the present invention, and the embodiments herein, can be adapted to smaller and larger ammunition.

[0056] For example, the cartridge case 60 has a front end that holds the bullet (not shown) and a rear end that holds the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com