Shock absorbing lanyards

a technology of applied in safety belts, weaving, sport apparatus, etc., can solve the problems of manual relative length adjustment of webbings, and increased risk of falling and injury of workers and other personnel who have occupations which require them to be at elevated positions, etc., to improve shock absorption and lanyards, the effect of improving the shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention provides new lanyards. The present invention particularly provides new shock absorbing lanyards which can stop a person or object from falling and reduce shock to the person or object. One new shock absorbing lanyard according to the present invention has a shock absorbing member or web woven with a load bearing web. The present invention, however, can be practiced in many different embodiments.

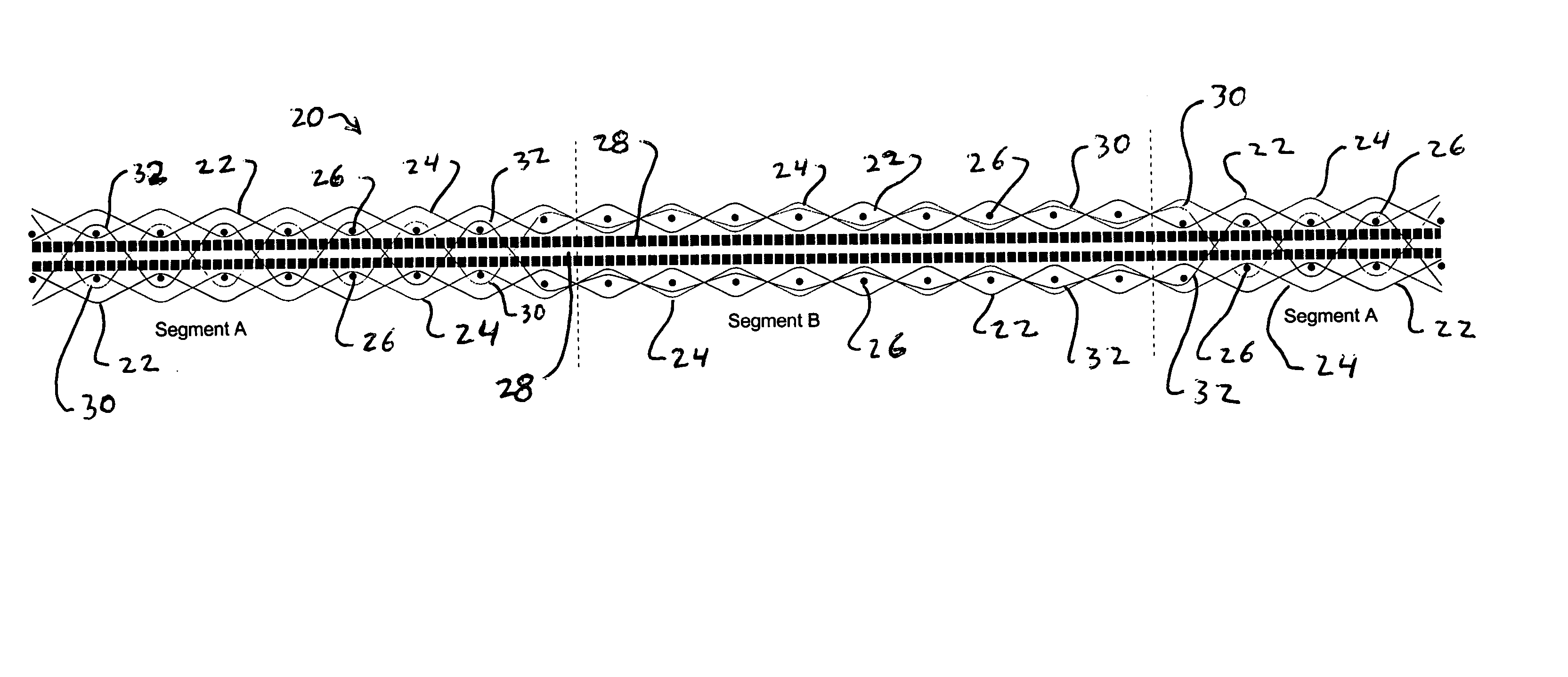

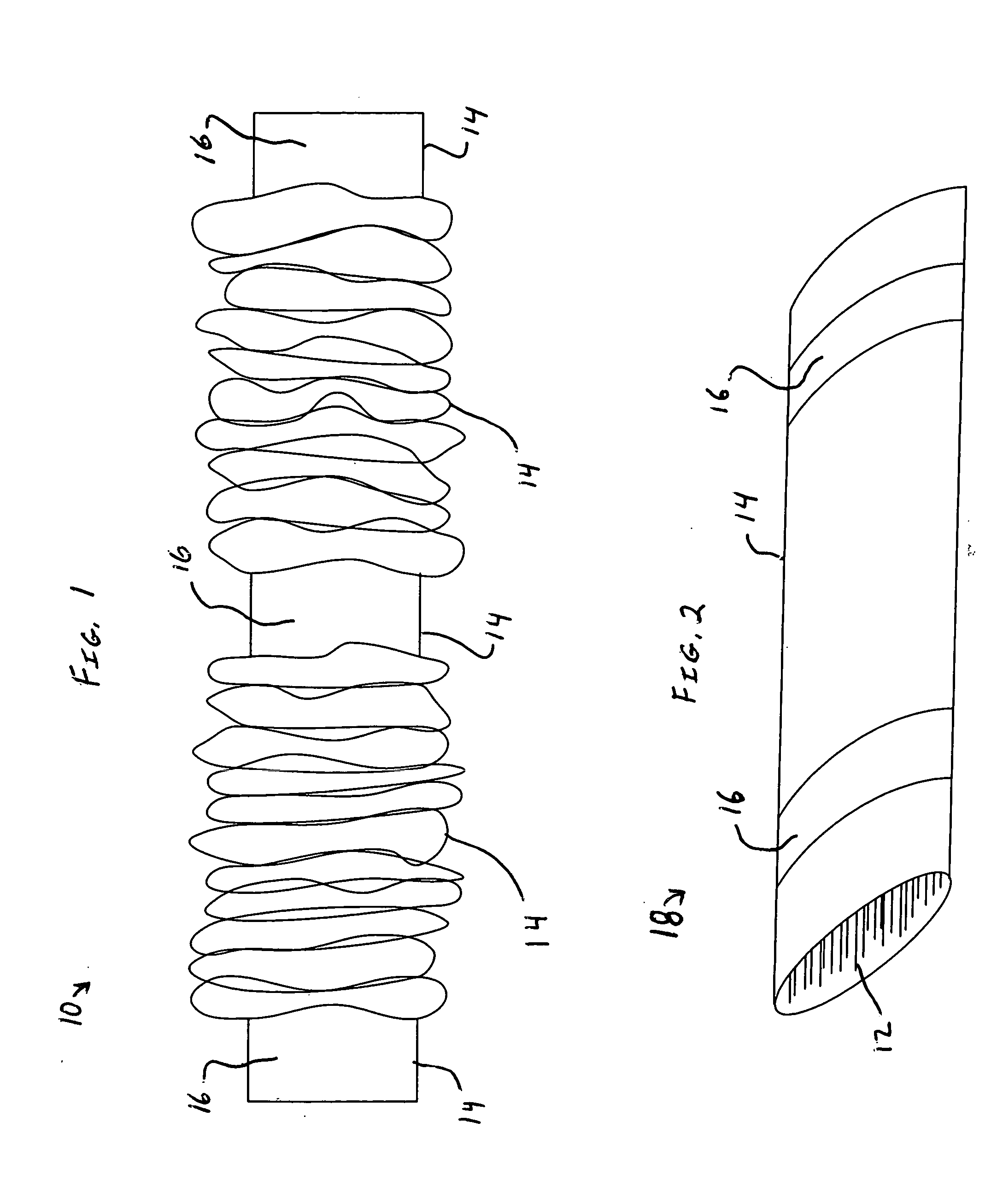

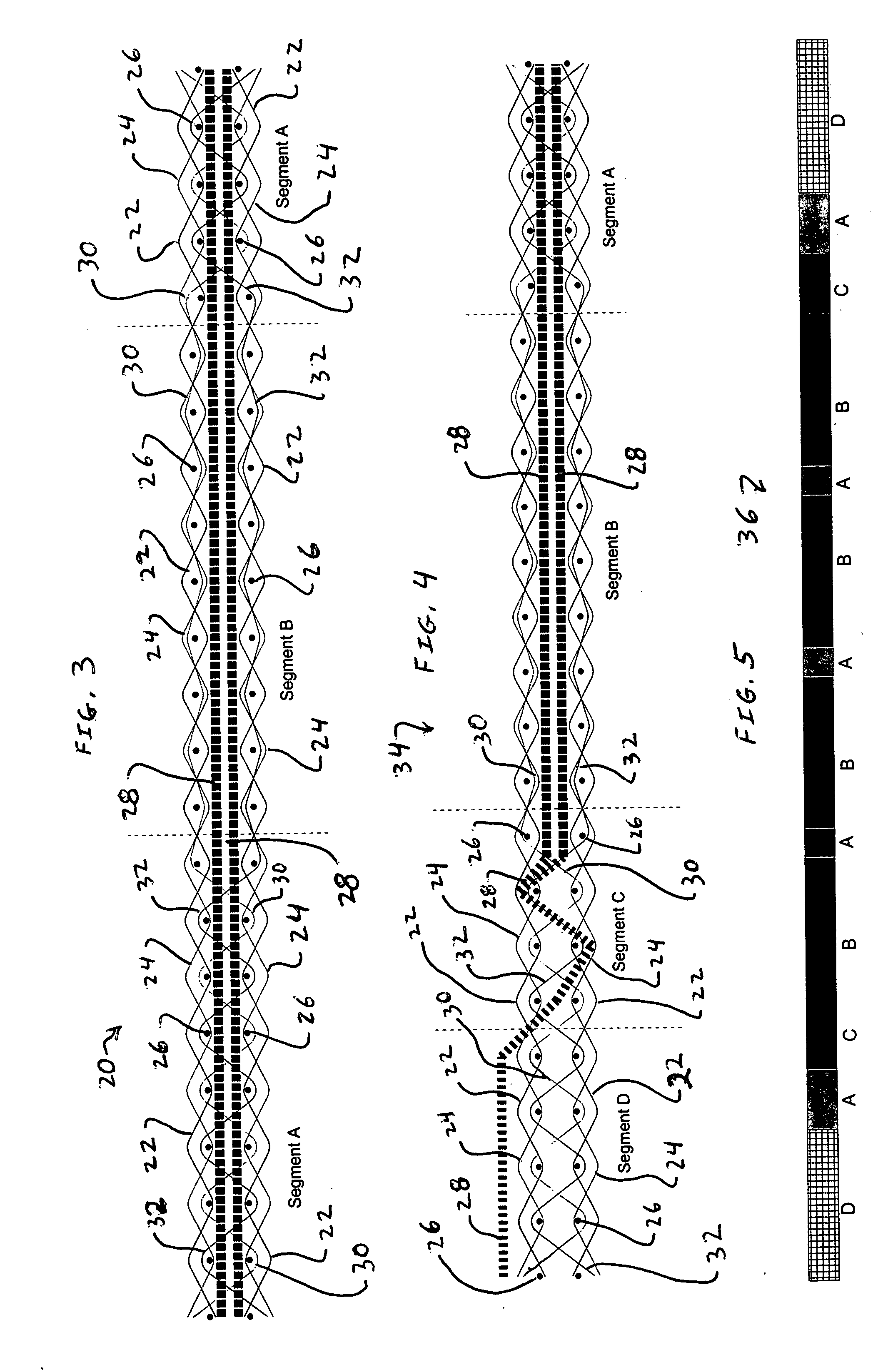

[0043] An example of the present invention is shown in FIG. 1 which shows a shock absorbing lanyard 10. The shock absorbing lanyard 10 is a woven webbing having high elongation yarns 12 (see FIG. 2) inside of a woven outer sheath or shell 14 of high strength yarn. The high elongation yarns 12 are highly extensible and significantly stretch when placed under a suitable tensile load. The high elongation yarns 12 can have any desired configuration, such as woven together or non-woven, for example. The high elongation yarns 12 are one example of shock absorbing membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com