System and method for controlling drill motor rotational speed

a technology of rotating speed and drill shaft, which is applied in the direction of drilling rods, drilling pipes, drilling holes/well accessories, etc., can solve the problems of excessive wear of the rotor and/or other components of the drill string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

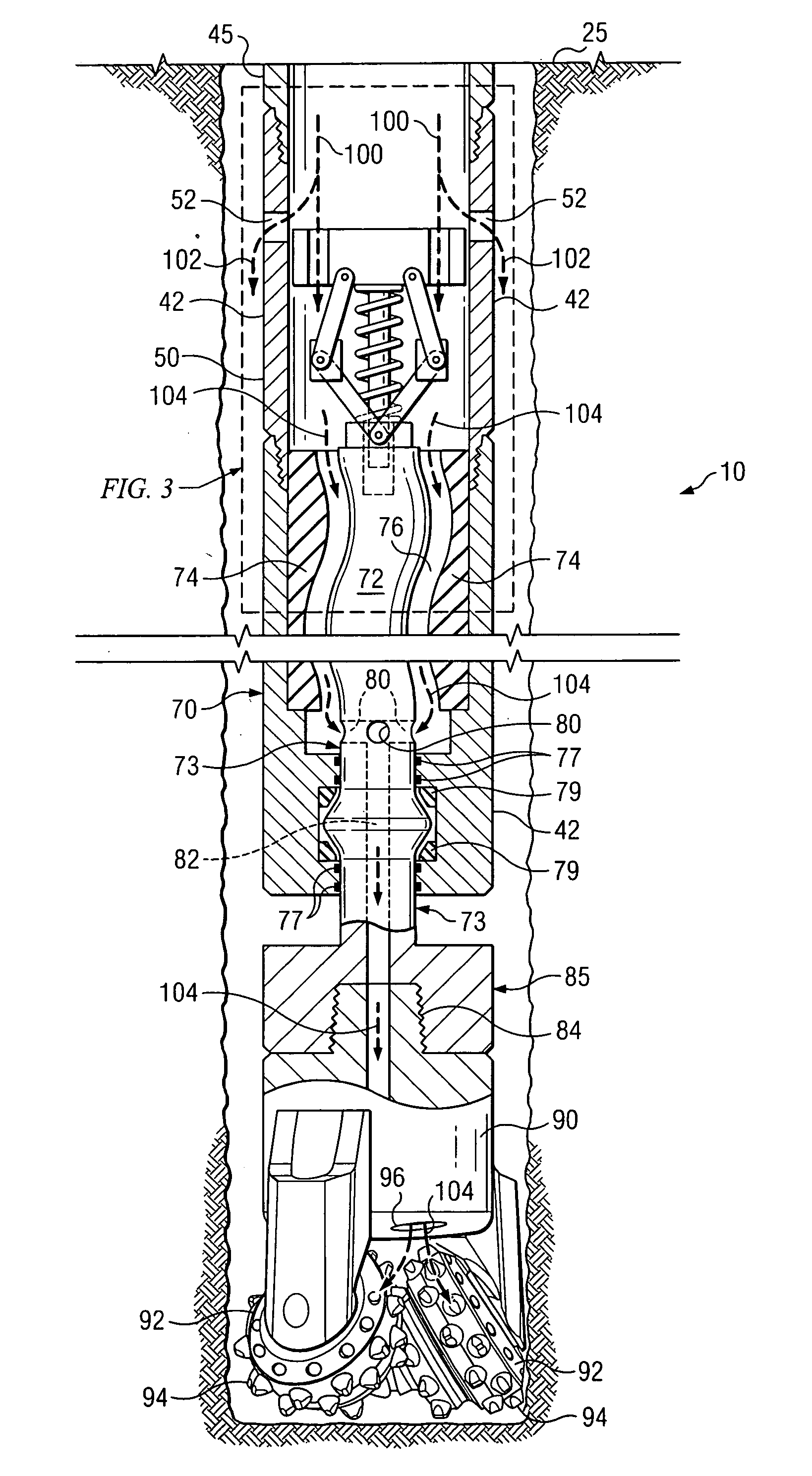

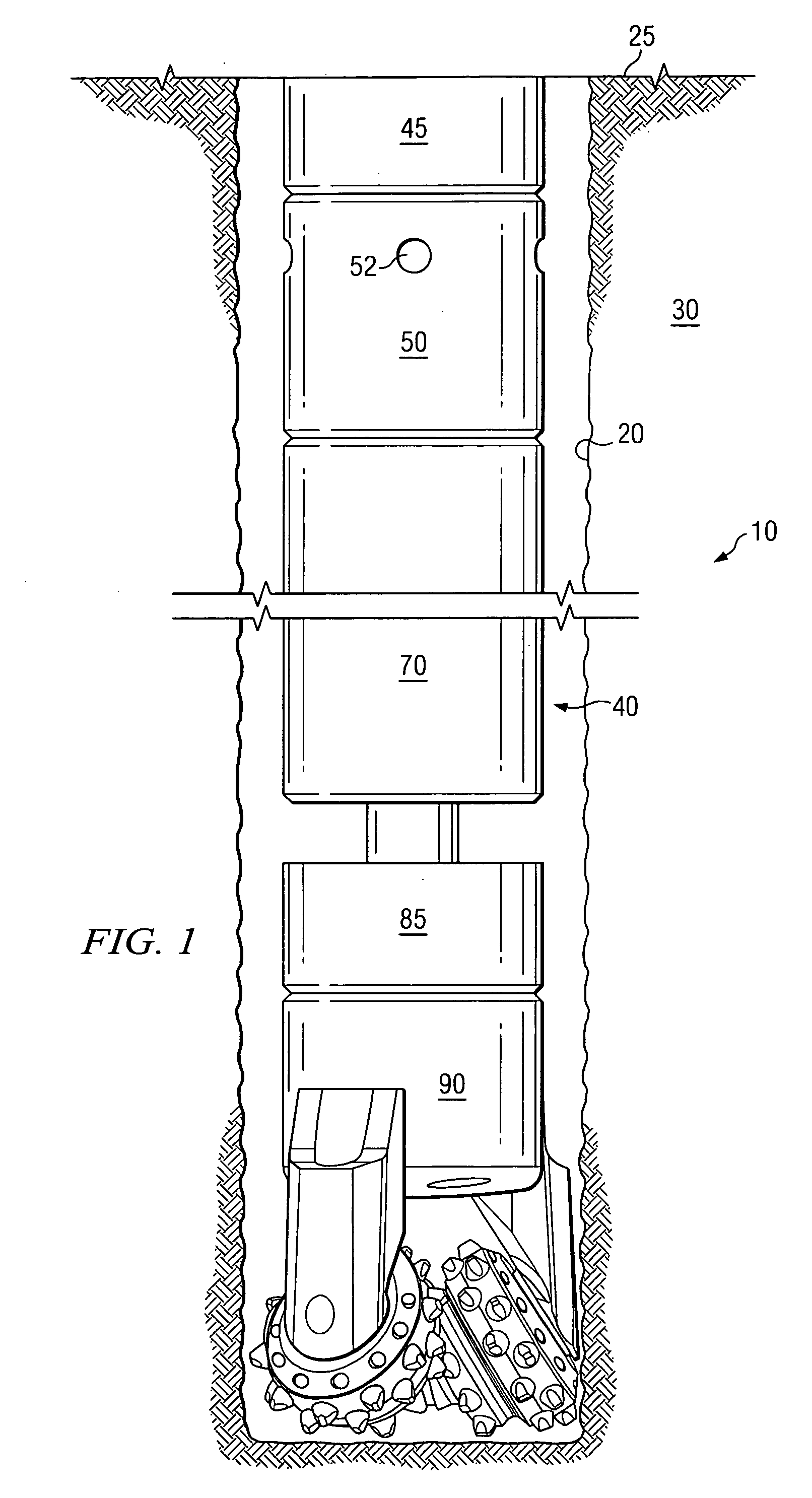

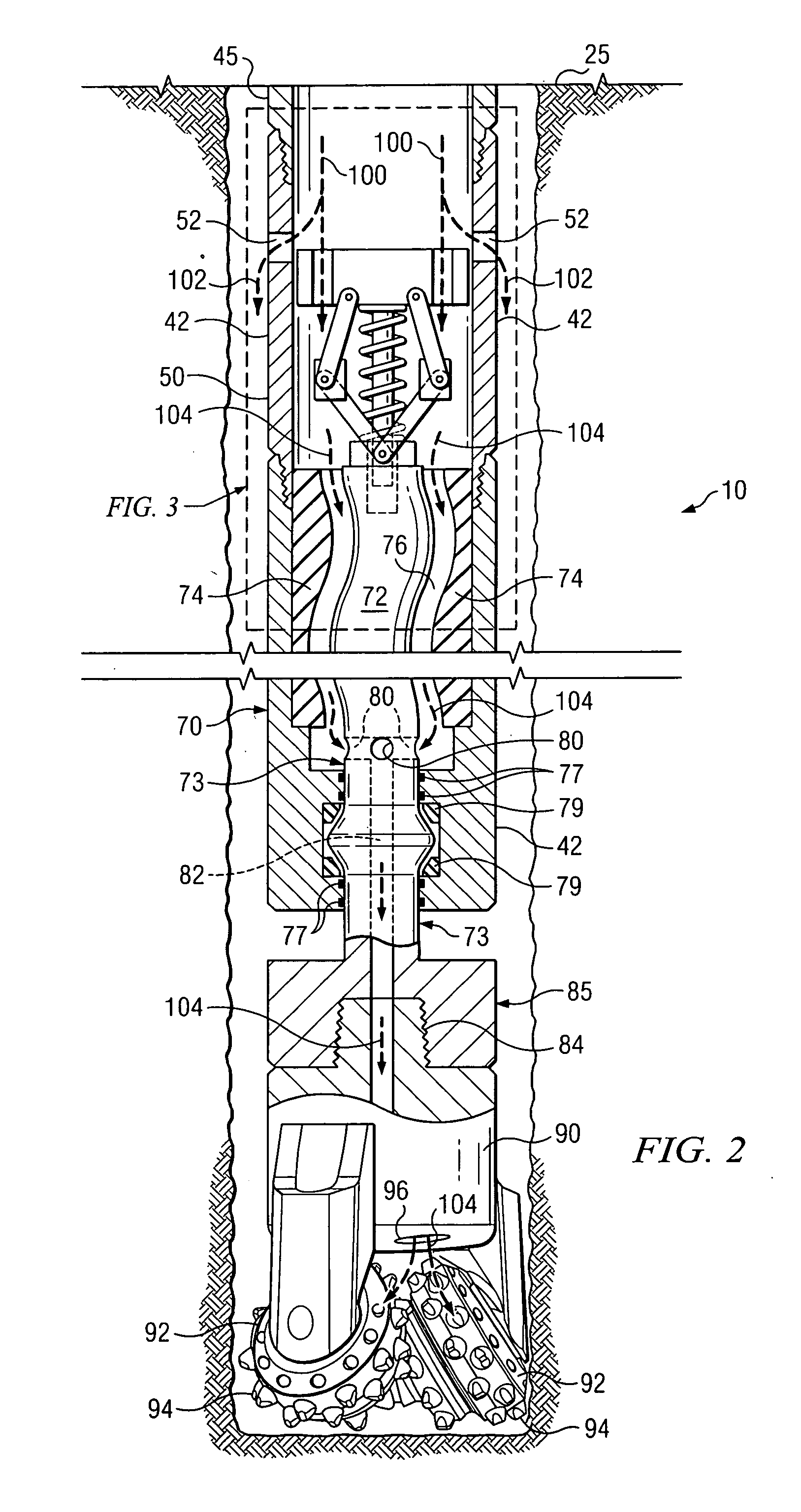

[0011]FIG. 1 illustrates an example system 10 for controlling drill motor rotational speed. In certain embodiments, system 10 may be used in a well bore 20 extending from surface 25 to penetrate a subterranean zone 30. Although FIG. 1 illustrates a substantially vertical well bore 20, system 10 may be implemented in articulated wells, slant wells, or any other types of wells or well systems. Subterranean zone 30 may comprise an oil or gas reservoir, a coal seam, or any other appropriate subterranean zone. Subterranean zone 30 may be accessed to remove and / or produce water, hydrocarbons, and other fluids in subterranean zone 30, to treat minerals in subterranean zone 30 prior to mining operations, or for any other suitable purpose.

[0012] System 10 includes a drill string 40 used to form well bore 20. In certain embodiments, drill string 40 includes a drill pipe 45, a motor governor 50, a downhole motor 70, a bit box 85, and a drill bit 90. Drill pipe 45 couples to motor governor 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com