Dimensionally stable balloons

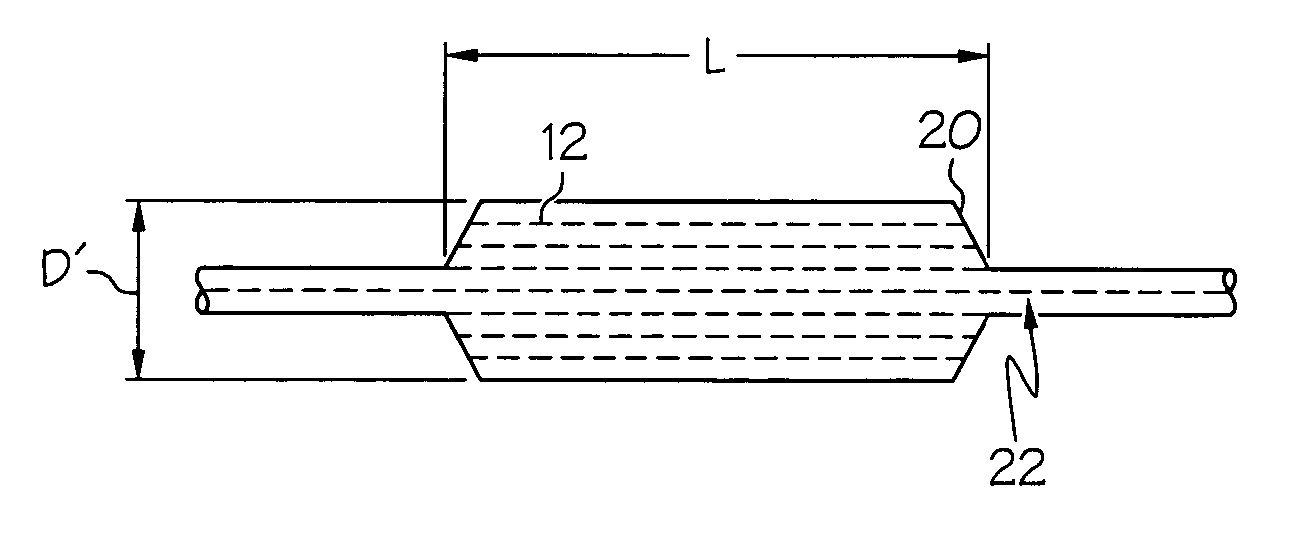

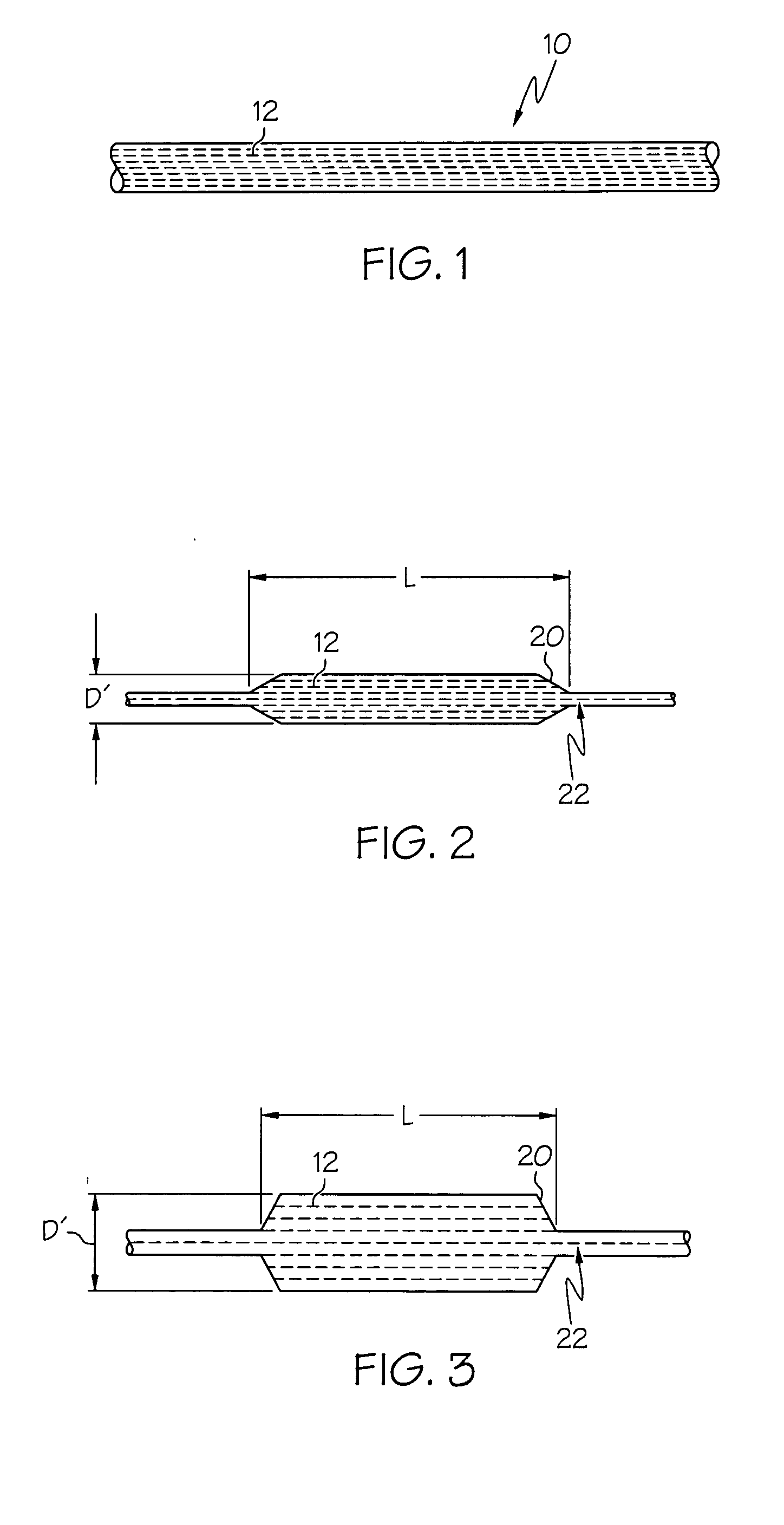

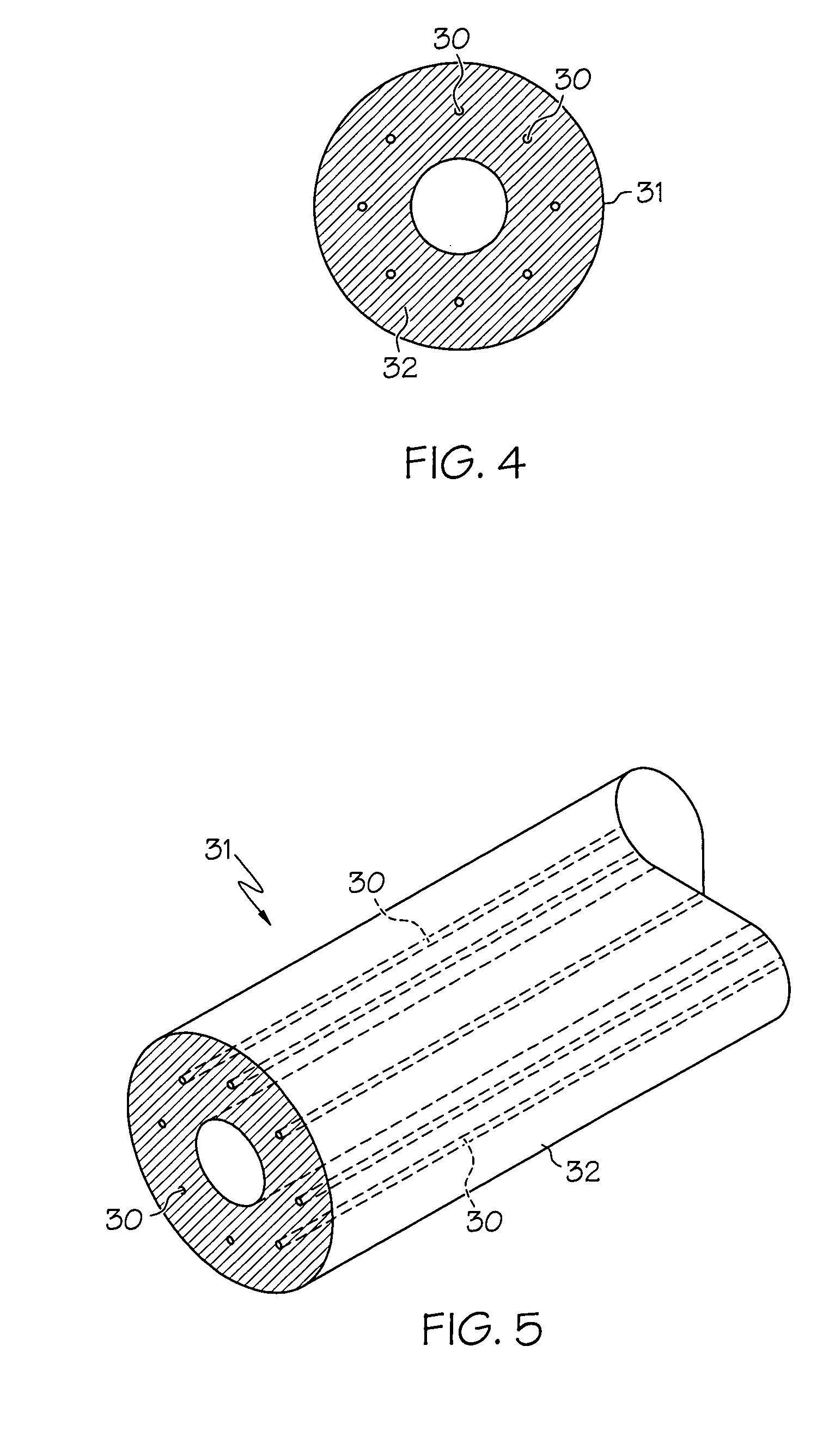

a balloon and stable technology, applied in the field of balloons with stable dimensions, can solve the problems of balloons expanding longitudinally, stent edges pushing against the vessel wall to a greater extent, improper delivery of medical devices, etc., and achieves the effect of minimal longitudinal expansion and minimal radial growth during expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0035] a matrix component of Pebax 7033 was mixed with a fibril component of LCP VECTRA LKX 1107 at the ratio of 95% to 5% respectively by weight. The mixture was extruded at a rate of 110 feet / minute line speed into tubing of 0.039 (outer diameter)×0.027 (inner diameter) inch. A 3.5 mm balloon was formed from the resulting tubing by radial expansion at 110 degrees Celsius with blowing pressure of 350 psi. The balloon with double wall thickness of 0.0014 inch was inflated from 4 atm to 13 atm at 1 atm increment and no measurable balloon length change was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com