Structure of fluid container and method and apparatus for producing the fluid container

a technology of fluid container and manufacturing apparatus, which is applied in the direction of paper/cardboard containers, envelope/bag making machinery, manufacturing tools, etc., can solve the problems of not being able to recycle styroform, soot is produced, flake or chip comes off, etc., to achieve high reliability, reduce the effect of production cost and maintaining the expansion of the fluid container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

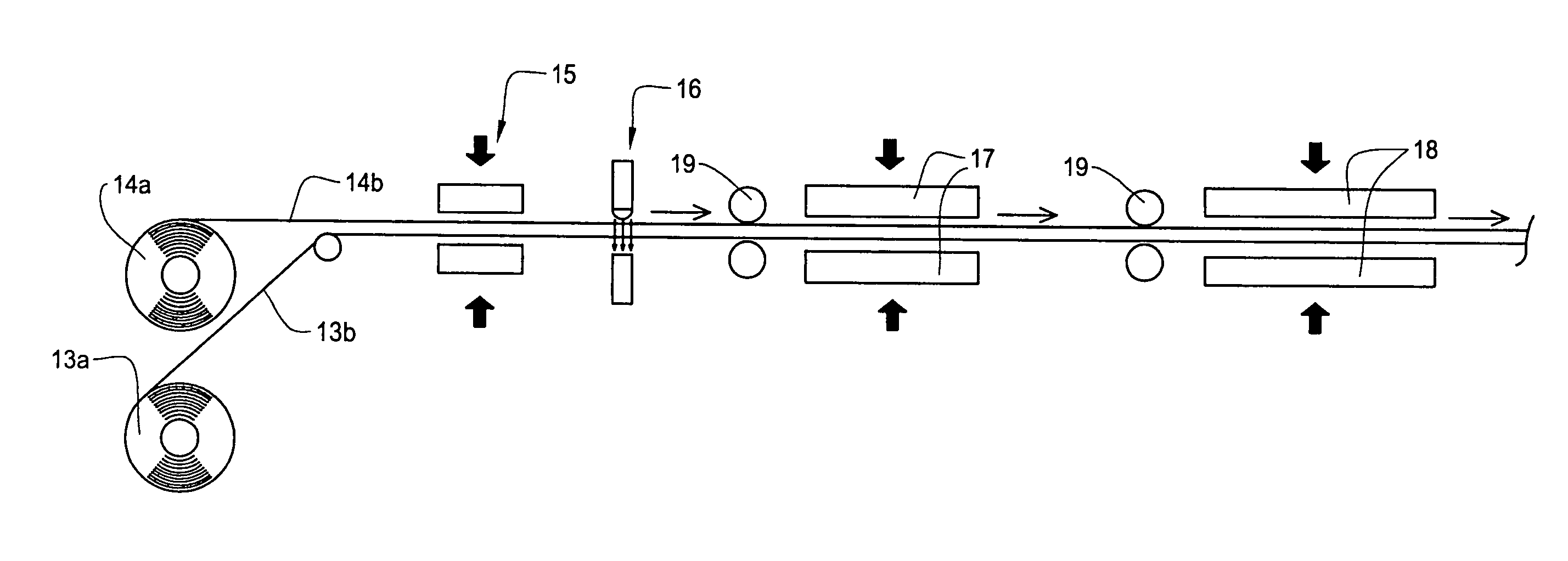

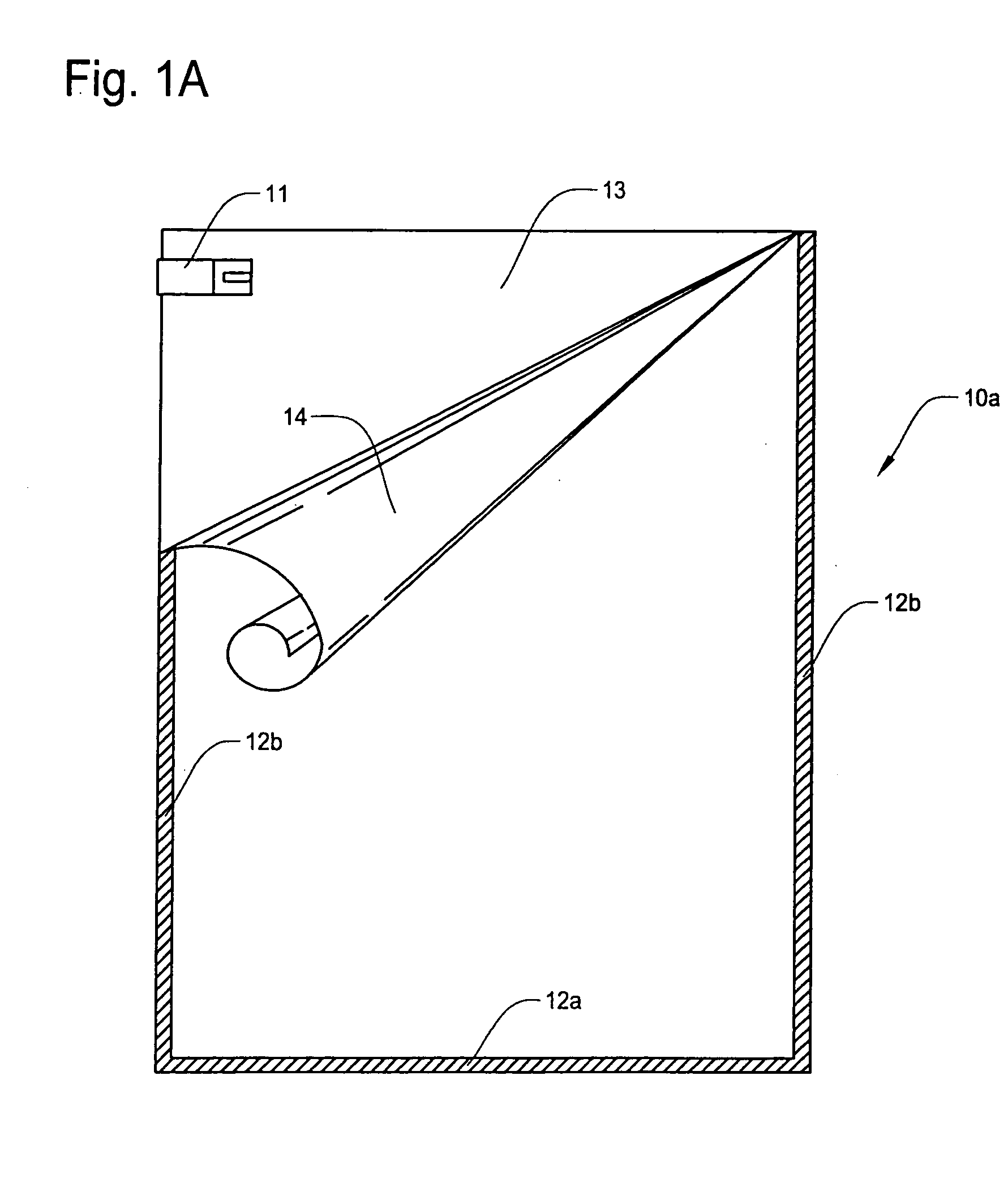

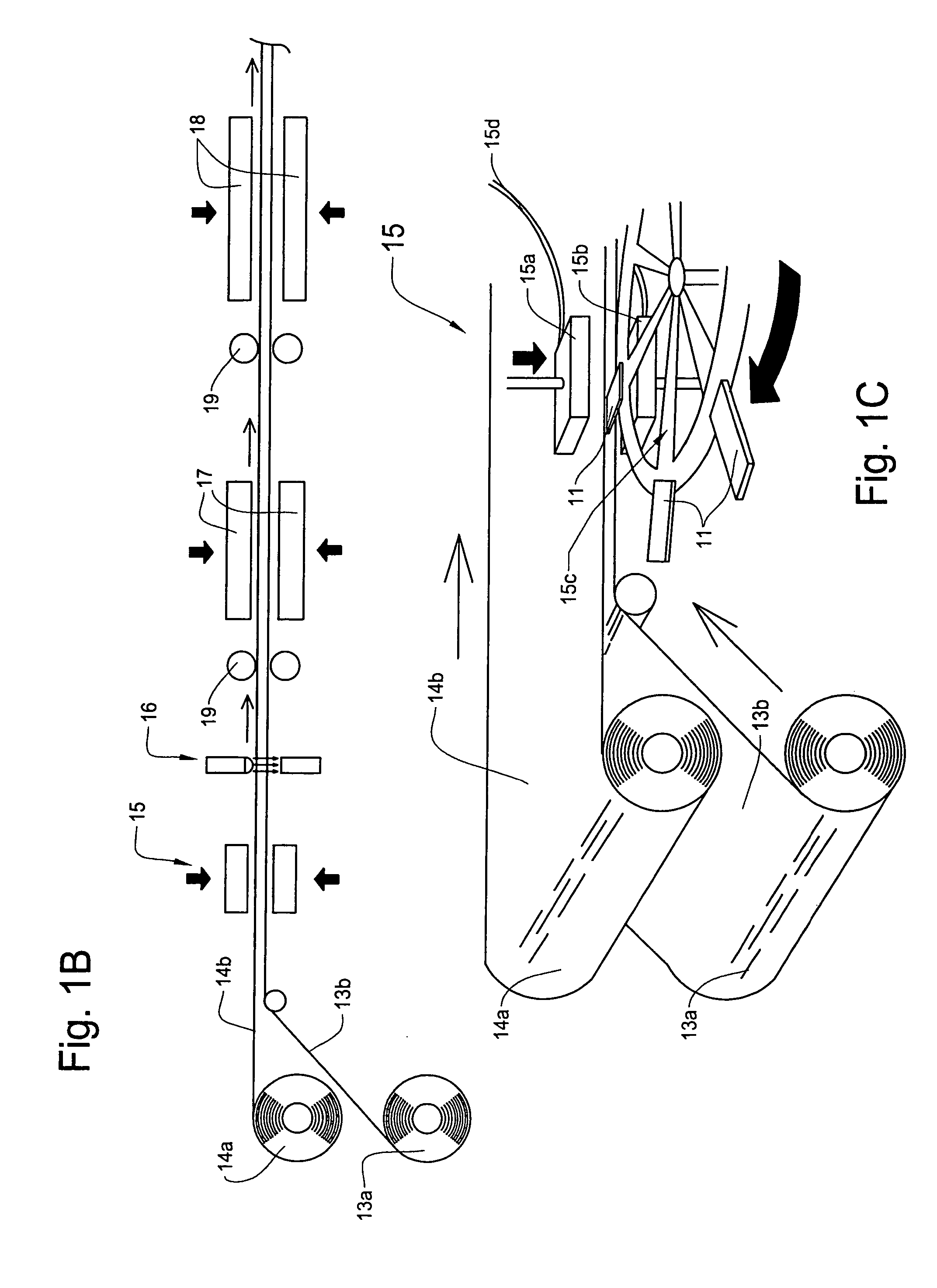

[0034] The present invention provides a method and apparatus for producing a fluid container with a reliable structure of check valve. As mentioned in the background of the invention, the check valves for the fluid container in the conventional technology are not reliable when the container is inflated. As shown in FIG. 2D, the sealed portions of the check valve are pressed inwardly and the check valve body becomes wavy. As a result, the fluid pipe in the check valve to prevent the reverse flow is easily opened, thereby causing the leakage. Also, the check valve needs to be attached more accurately to the fluid container.

[0035] A check valve in the present invention is designed to solve these problems. To avoid the check valve wavy, the check valve is not bonded to both container plastic films, but to only one of the container plastic films. Also, to increase the accuracy of attaching the check valve to the container members, a check valve having a special structure is used for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| feed length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com