Insulated pitched roof system and method of installing same

a pitched roof and insulation technology, applied in the field of pitched roof systems and methods, can solve the problems of affecting the fixing effect of nails, and unable to drive holes through the roof substrate and wood deck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

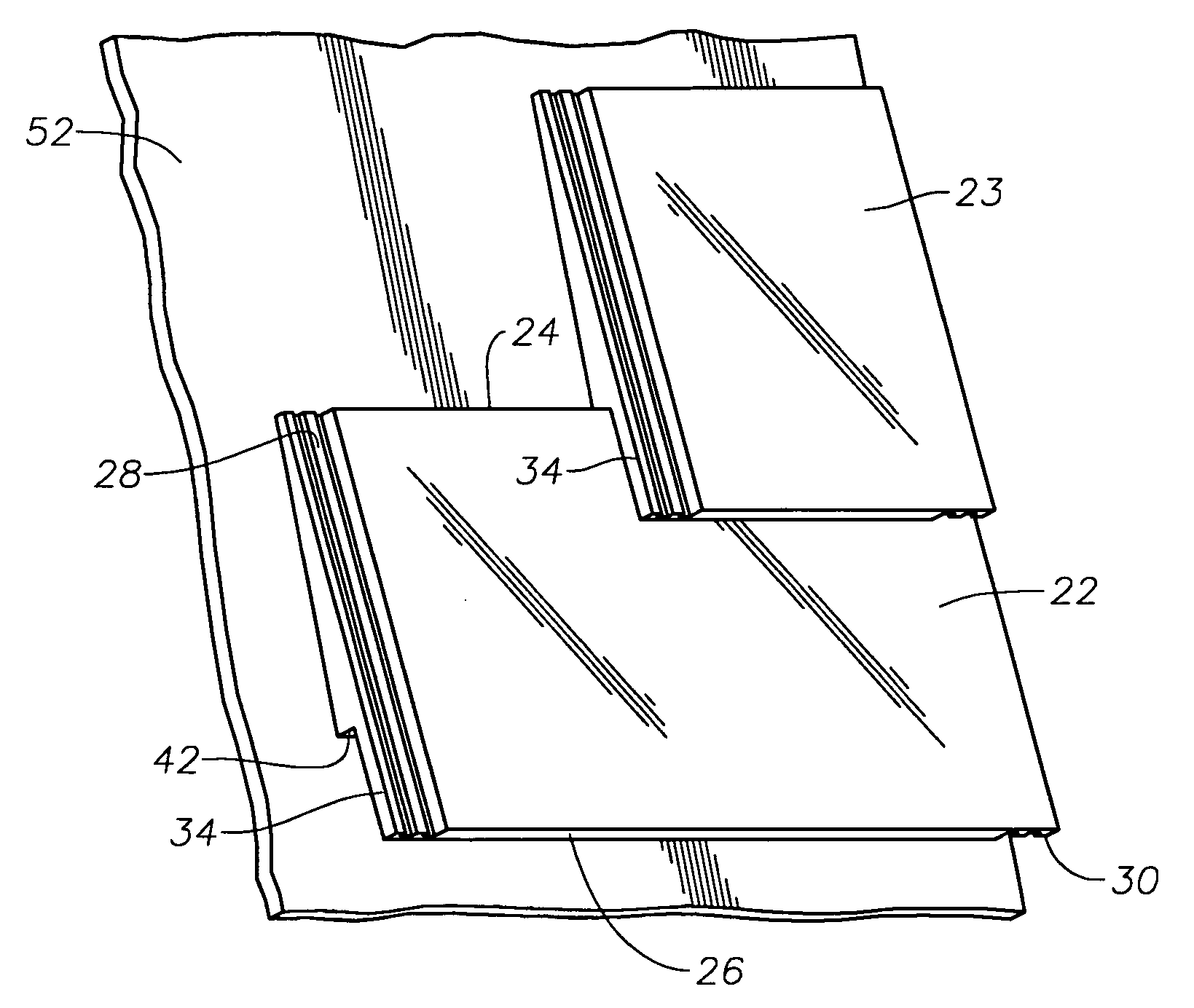

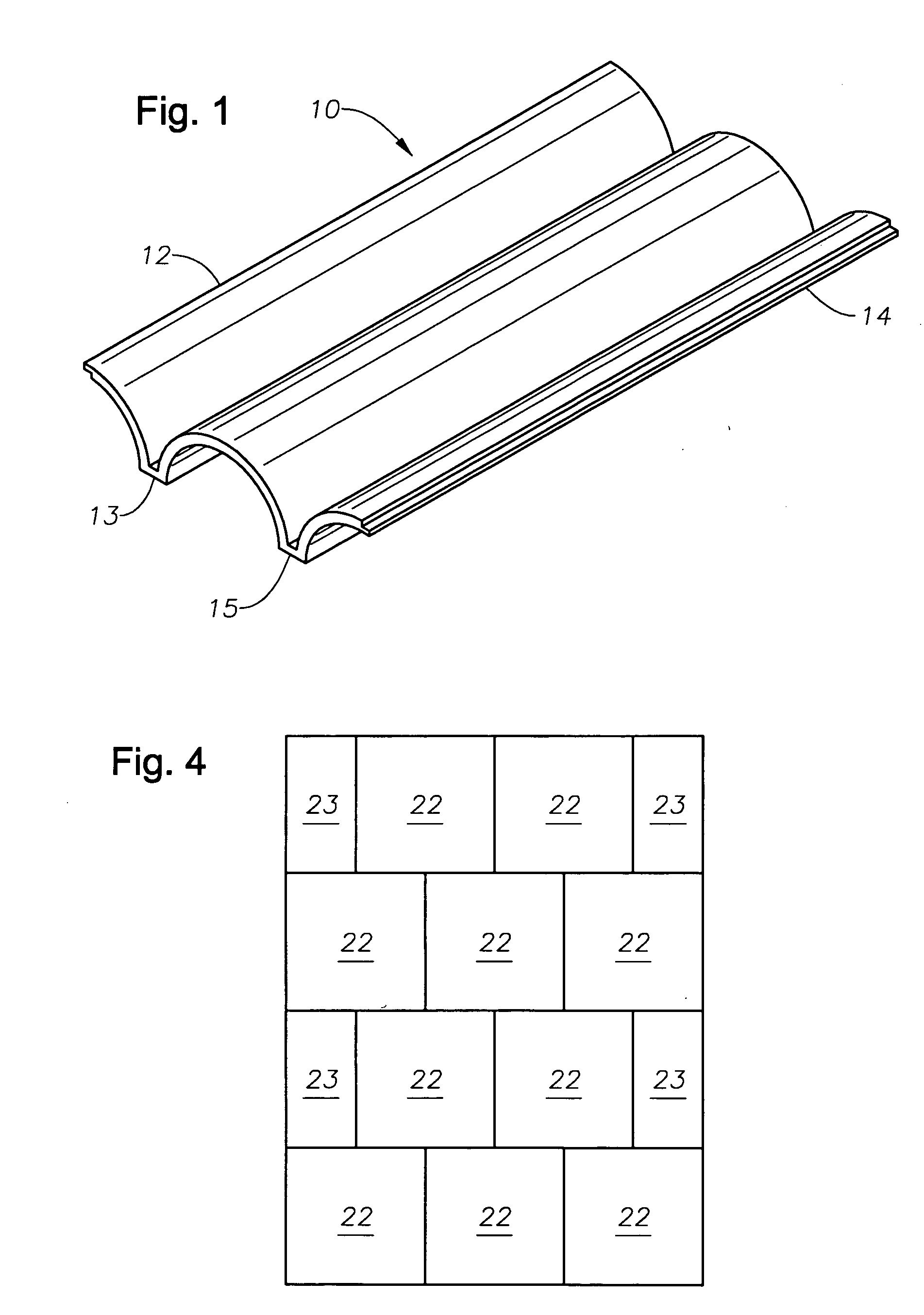

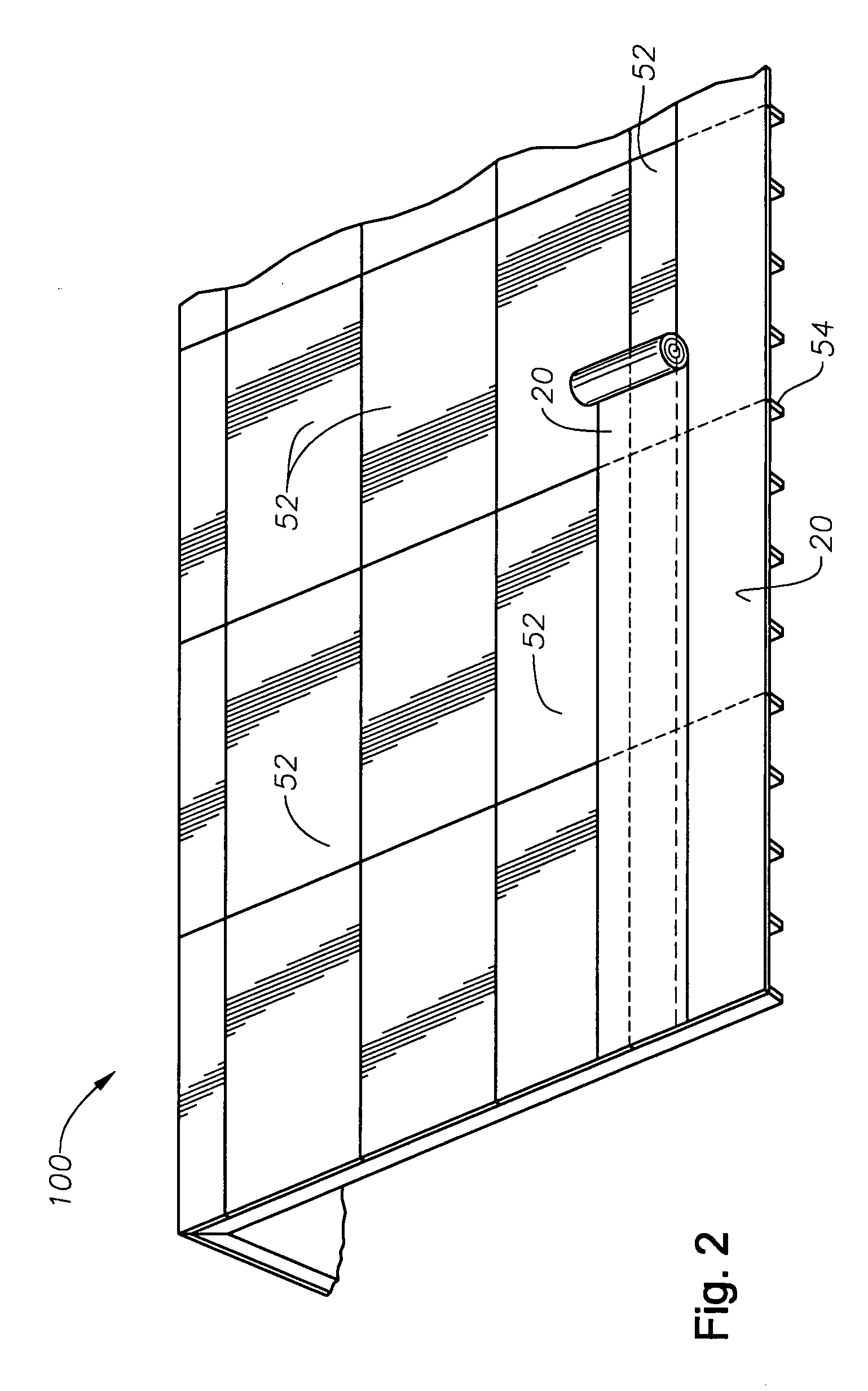

[0029] The insulated pitched roof system and method of installing same, generally designated as 100, will now be described in greater detail with specific reference to the drawings. Referring to FIG. 1, the pitched roof system 100 includes a roof component, designated generally as 10. The roof component 10 shown in perspective view in FIG. 1 is known as a semi-circular roof tile. It is to be understood that the system and method of the present invention 100 is not limited to semi-circular roof tiles. Rather, the system and method 100 can include roof components 10 of other types and configurations. For example, flat roof tiles and reverse curve roof tiles are just a few of the other types that can be used with the system and method 100. Typically, the tile components 10 are made from cementitious or clay materials. It is also to be understood that the system and method of the present invention 100 is not limited to clay or cementitious roof tiles 10 but is also applicable to roof co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com