Control valve for variable displacement compressor

a variable-discharge compressor and control valve technology, which is applied in the direction of pump control, positive-discharge liquid engine, machines/engines, etc., can solve the problems of inability to achieve sufficient improvement of compression efficiency, the flow rate of refrigerant circulating in the compressor cannot be reduced to a limited degree, and the compression efficiency is reduced. , to achieve the effect of improving compression efficiency and stable controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be described in detail with reference to the accompanying drawings showing preferred embodiments thereof.

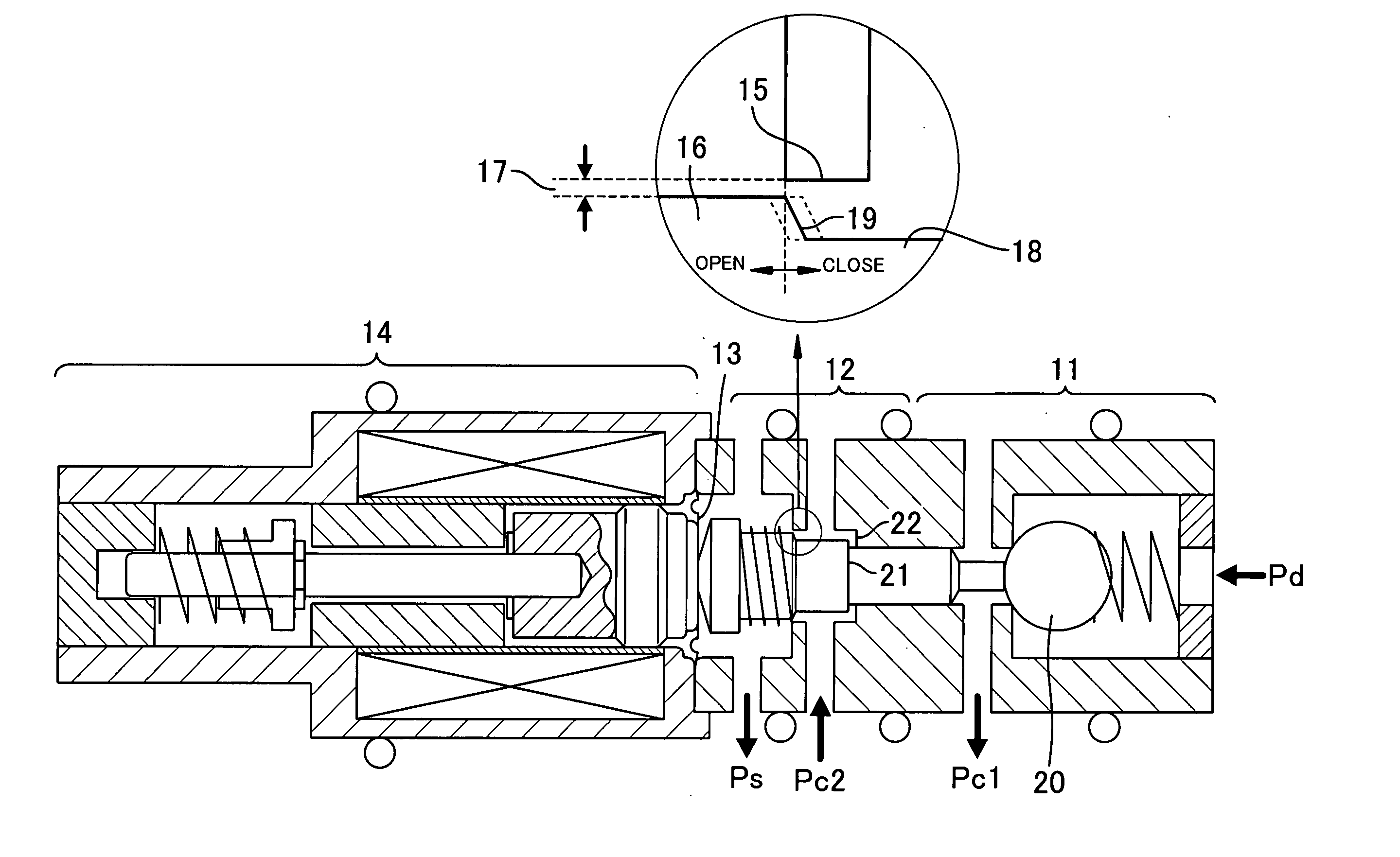

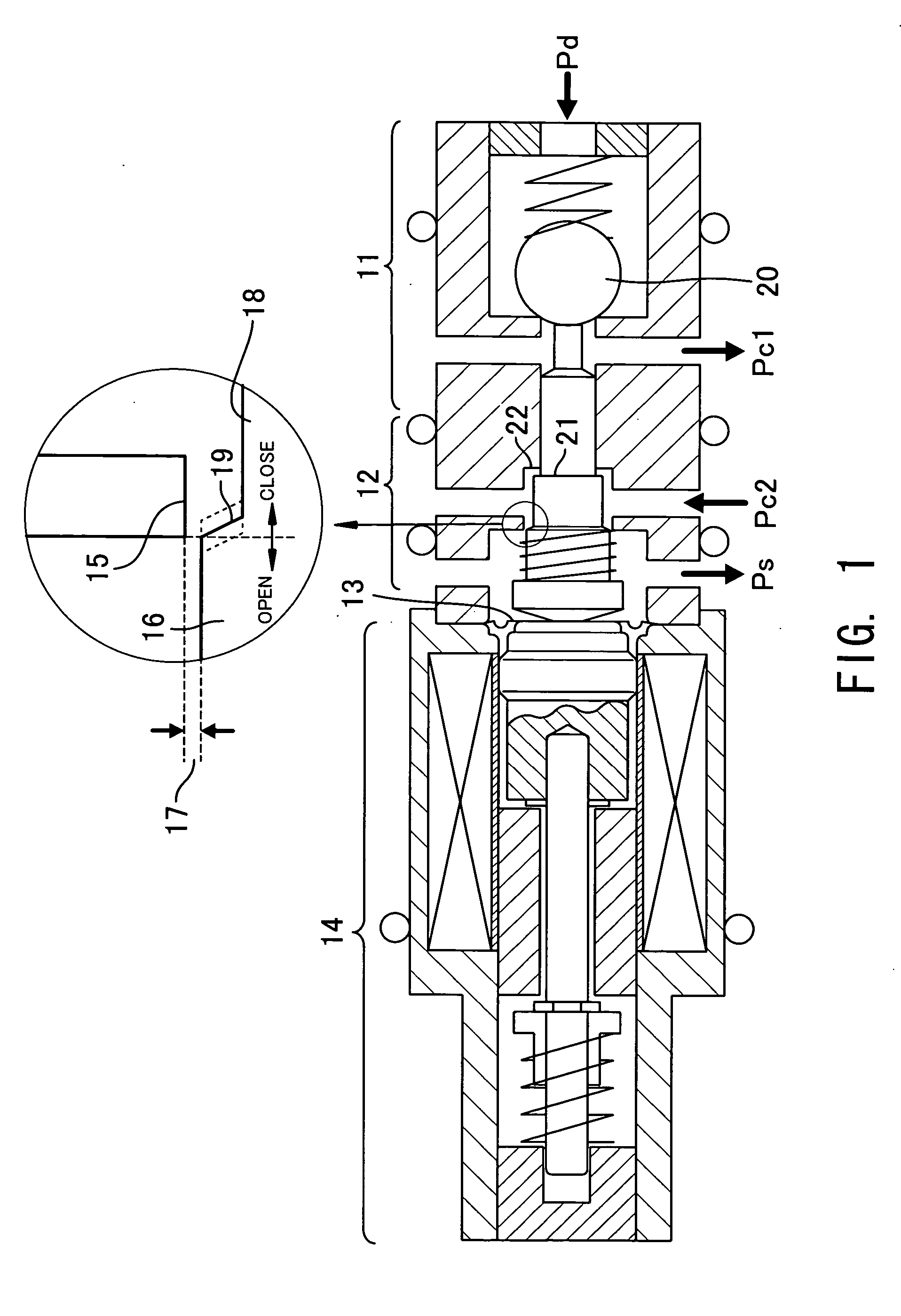

[0031]FIG. 1 is a conceptual view showing the arrangement of a control valve for a variable displacement compressor, according to the present invention.

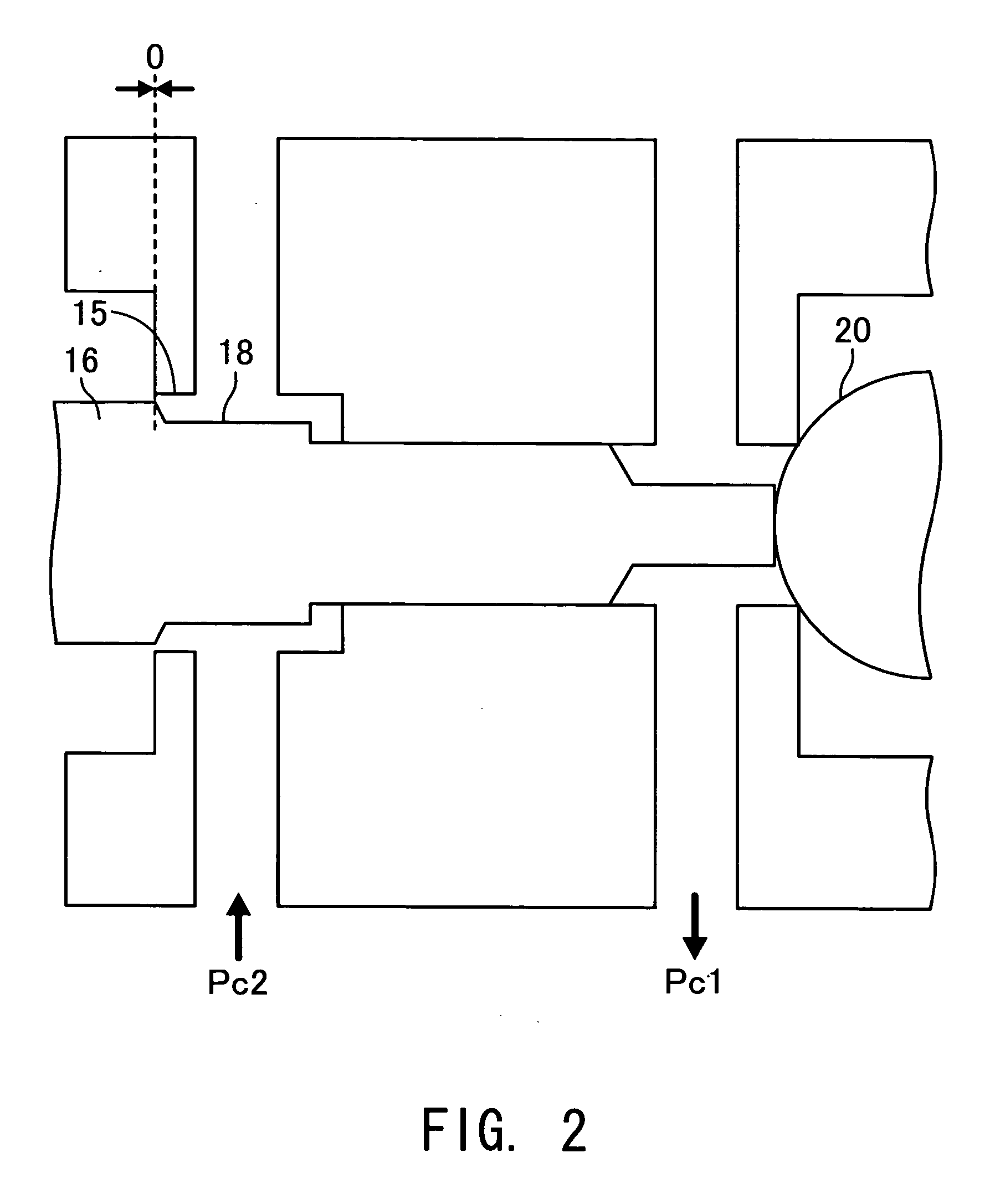

[0032] The control valve for a variable displacement compressor, according to the present invention has a ball valve 11 forming a first valve, a spool valve 12 forming a second valve, a diaphragm 13 forming a pressure-sensing section, and a solenoid 14 forming a pressure-setting section, which are arranged in the mentioned order.

[0033] The ball valve 11 introduces refrigerant discharged at discharge pressure Pd from a discharge chamber of the variable displacement compressor, and controls the flow rate of the introduced refrigerant to supply the refrigerant at pressure Pc1 to a crankcase. The spool valve 12 introduces refrigerant delivered at pressure Pc2 from the crankcase, and controls th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com