Radiation-curable high gloss overprint varnish compositions

a technology of overprint varnish and composition, which is applied in the field of radiation curable overprint varnish, can solve the problems of less formulating options, and achieve the effects of less shrinkage, improved adhesion, and softer and flexibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

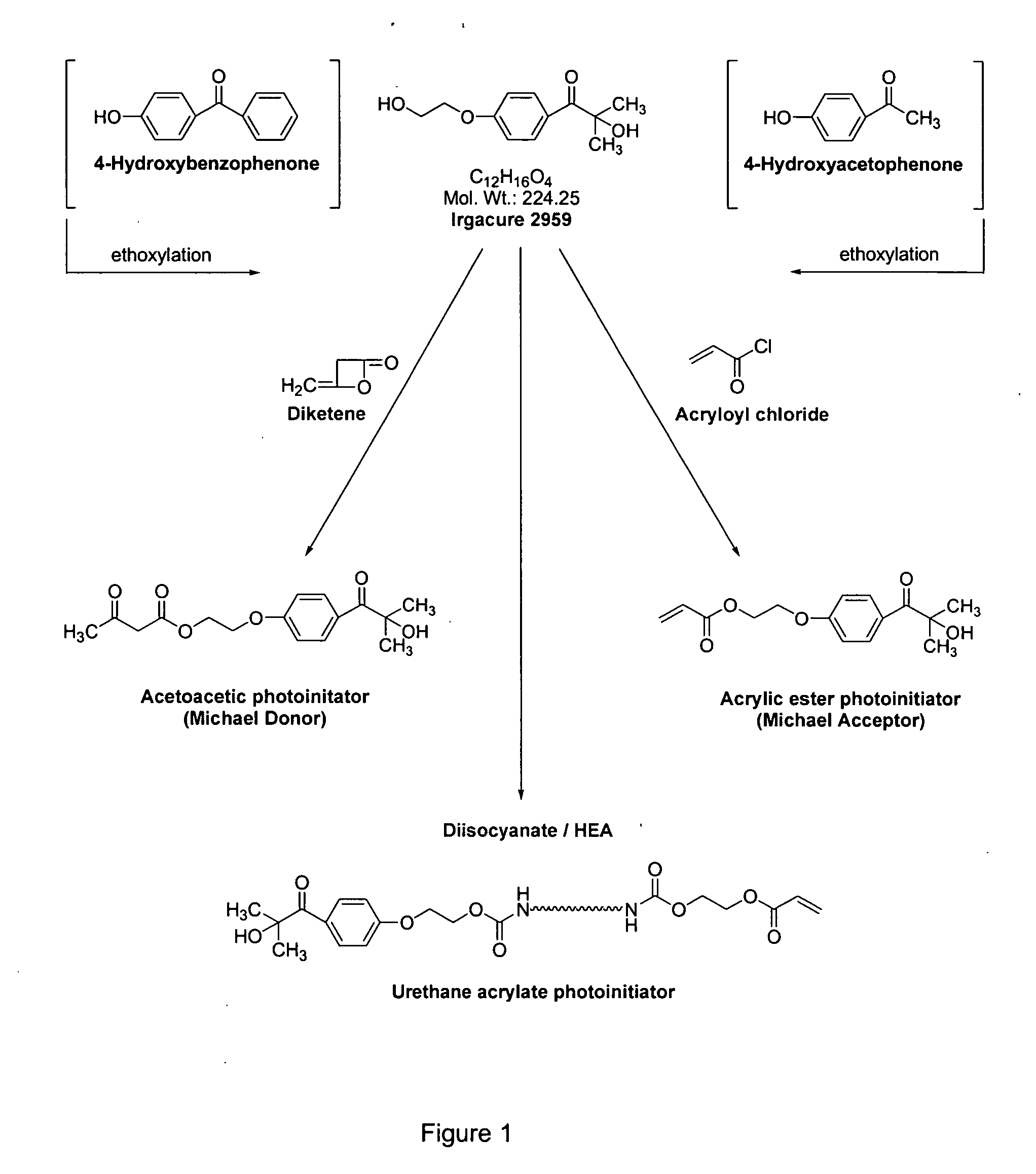

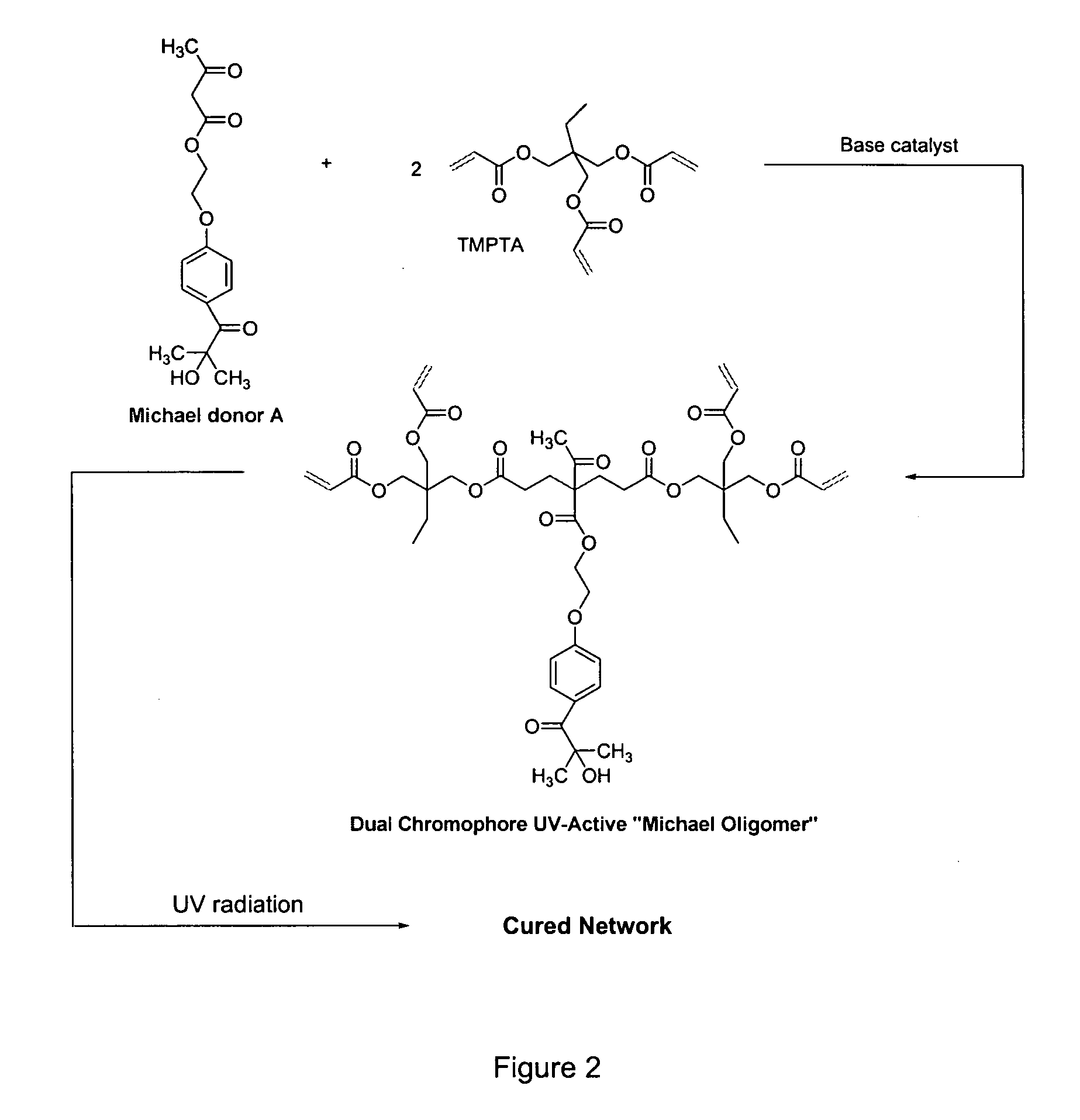

Method used

Image

Examples

example 1

OPV Formulation Based on FlexCure Resins

[0053] The final formulation (OPV-062503-01) is comprised of FlexCure resins and commercial raw materials, in parts by weight, as specified in Table 1A:

TABLE 1AFormulation (components in parts by weight).Raw MaterialDescriptionParts (w / w)7001-152Ashland self-initiating resin68.0TMPTAreactive diluent28.0Benzophenonephotoinitiator1.0MDEAamine synergist0.4HCPKphotoinitiator0.6TegoRad 2300siloxane-based flow agent2.0100.0

example 2

OPV Formulation Based on FlexCure Resins

[0054] The final formulation (OPV-102003-02) is comprised of FlexCure resins and commercial raw materials, in parts by weight, as specified in Table 2A:

TABLE 2AFormulation (components in parts by weight).Raw MaterialDescriptionParts (w / w)FlexCure Resin OPV120Ashland self-initiating resin60.0TMPTAreactive diluent36.0Benzophenonephotoinitiator1.0MDEAamine synergist0.4HCPKphotoinitiator0.6TegoRad 2300siloxane based flow agent2.0100.0

example 3

OPV Formulation Based on FlexCure Resins

[0055] The final formulation (OPV-070903-02) is comprised of FlexCure resins and commercial raw materials, in parts by weight, as specified in Table 3A:

TABLE 3AFormulation (components in parts by weight).Raw MaterialDescriptionParts (w / w)FlexCure OPV130Ashland self-initiating resin67.0TMPTAreactive diluent28.0Benzophenonephotoinitiator1.5MDEAamine synergist0.6HCPKphotoinitiator0.9TegoRad 2300siloxane based flow agent2.0100.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Dimensionless property | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com