Motor-mounted internal gear pump and electronic device

a technology of internal gear pump and motor, which is applied in the direction of piston pump, positive displacement liquid engine, instrument, etc., can solve the problems of increasing cost and reliability, increasing the size of the entire pump, and deteriorating reliability, and achieves small size and less cost. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0031] A motor-mounted internal gear pump and electronic device according to the invention will be explained with reference to FIGS. 1 to 4.

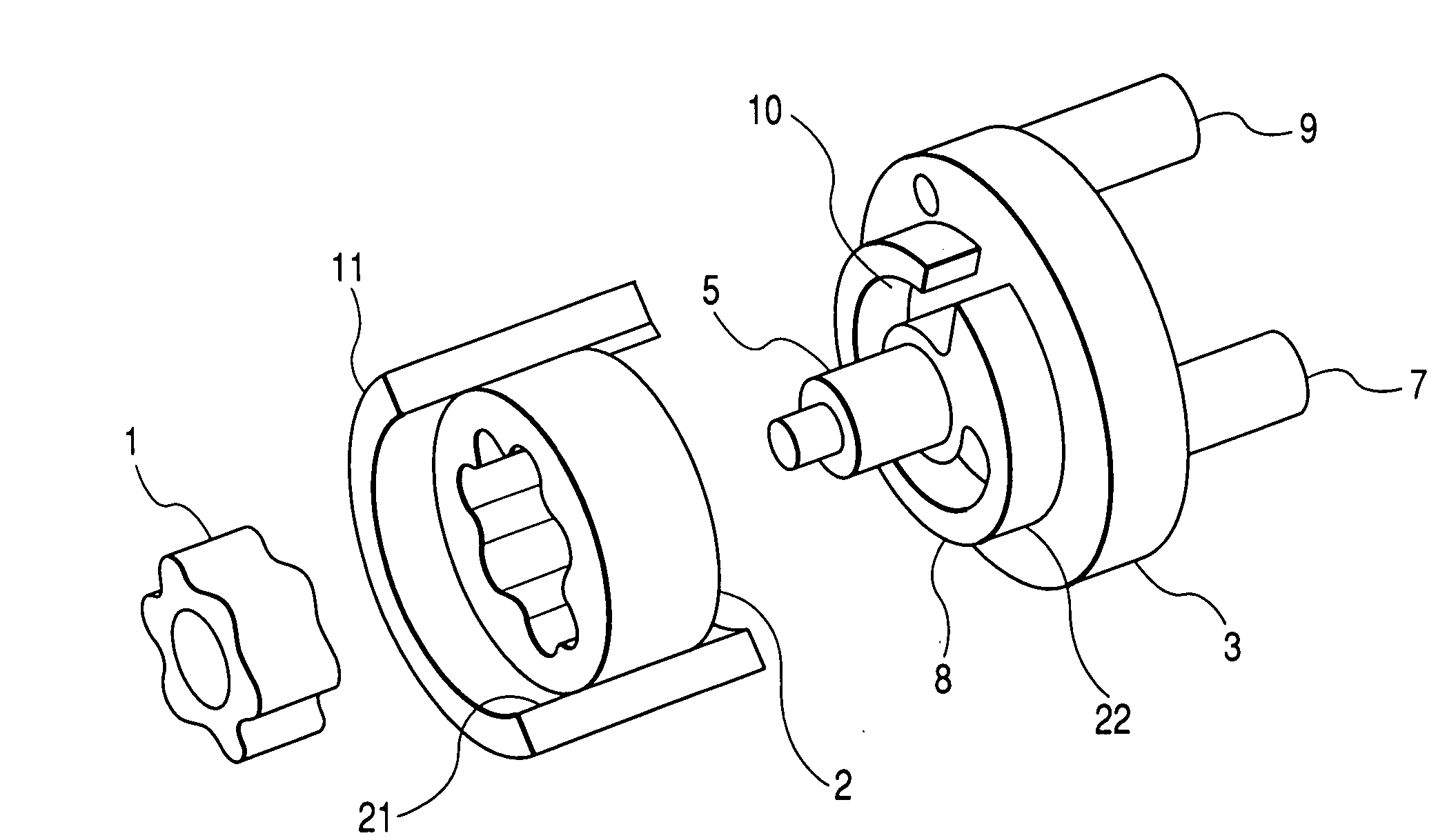

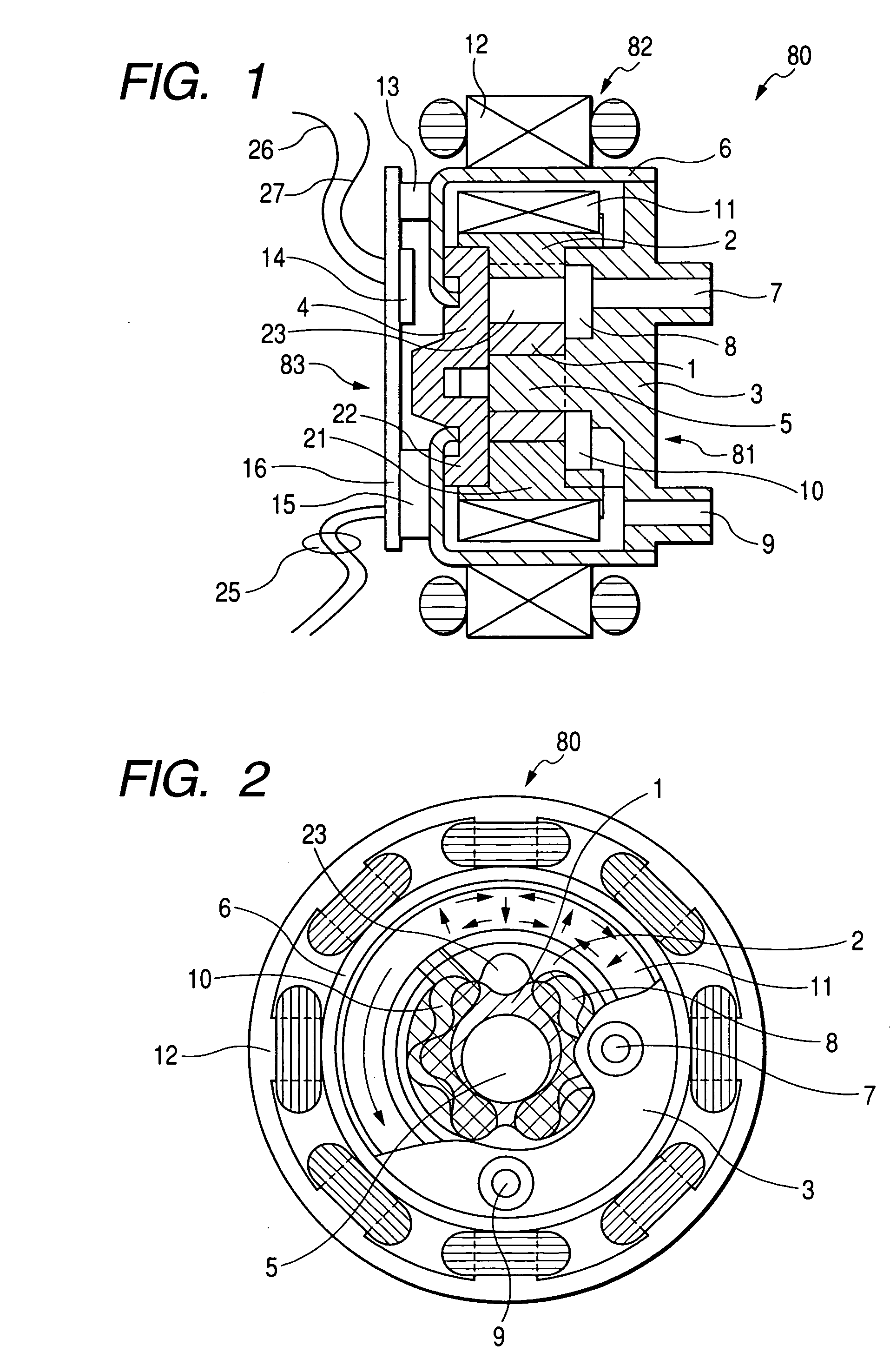

[0032] Firstly, the entire structure of the motor-mounted internal gear pump of this embodiment will be explained by using FIGS. 1 and 2. FIG. 1 is a longitudinal sectional view of the motor-mounted internal gear pump according to the first embodiment of the present invention, while FIG. 2 is a cross-sectional view of the motor-mounted internal gear pump of FIG. 1.

[0033] A pump 80 is a motor-mounted internal gear pump provided with a pump section 81, motor section 82 and control section 83. The pump 80 is formed into a thin-sized shape wherein the size in the diameter direction is greater than the size in the widthwise direction.

[0034] The pump section 81 is provided with an internal rotor 1, external rotor 2, front plate 3, back plate 4, internal shaft 5 and can 6.

[0035] The internal rotor 1 has a shape similar to a spur gear, wherein teeth ...

second embodiment

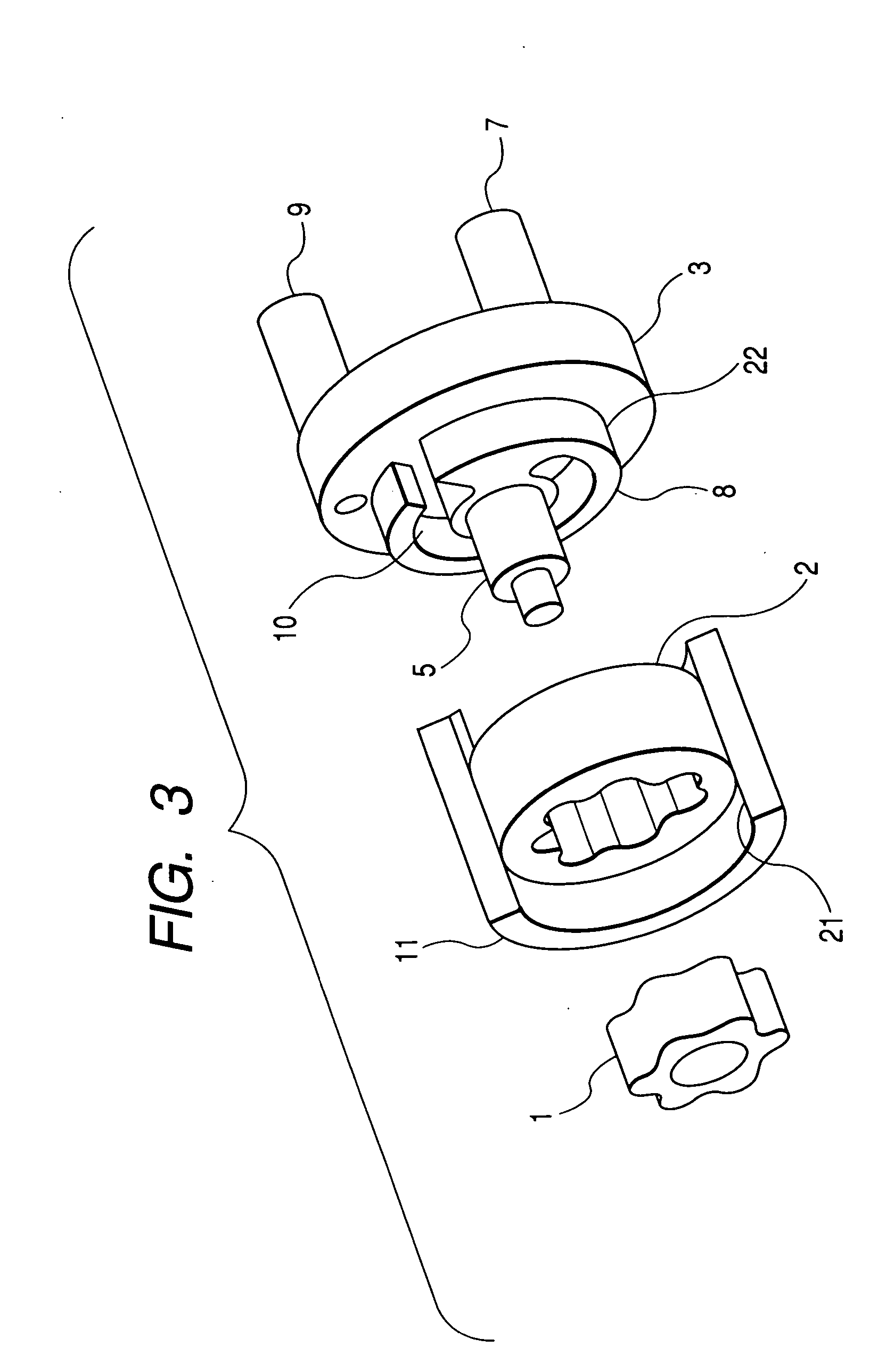

[0072] In this second embodiment, the permanent magnet 11 and the stator 12 are arranged so as to be close to one side in the shaft direction with respect to the internal and external rotors 1 and 2. The bracket section 21 is provided so as to project at only one side of the outer peripheral section of the external rotor 2. The permanent magnet 11 is arranged at the outside of the bracket section 21, and the stator 12 is arranged at the outside of the permanent magnet 11. The external rotor 2 is supported only by the shoulder section 22 of the front plate 3 via the bracket section 21. The internal rotor 1 is supported by the shaft 5 embedded into (i.e., integrally molded with) the front plate 3.

[0073] The can 6 is composed of the flange section 6a, cylindrical section 6b and bottom section 6c, wherein the bottom section 6c serves as the back plate 4 in the first embodiment. Accordingly, the pump casing is composed of two components, i.e., the front plate 3 and the can 6. Further, a ...

third embodiment

[0078] As described above, the structure of the third embodiment is that the internal rotor 31 is integrally supported by the shaft 35 at both ends and the external rotor 32 has the outer periphery and end face serving as a slide bearing. This structure is popular in a conventional internal gear pump, having long-period achievements and high reliability.

[0079] A partition plate 36 has a plane shape with a central opening. The driving shaft 35 penetrates through this central opening. The partition plate 36 covers the end face at one side of both rotors 31 and 32, and its peripheral section is fixed so as to be in close contact with the front plate 33. Formed at the partition hole 36 are a discharge port 36a that is a through-hole having a predetermined outline shape and also a flow channel communicating with the discharge opening 9.

[0080] The permanent magnet 11 is fixedly provided at the outer periphery of the driving shaft 35, where the diameter is increased, at the side opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com