Method and system for supplying carbon dioxide to a semiconductor tool having variable flow requirement

a technology of carbon dioxide and semiconductor tools, applied in the direction of container discharge methods, vessel construction details, cleaning using liquids, etc., can solve the problems of not providing a means of controlling the release of pressure in the buffer vessel, and the selection of temperature in the buffer volume is not recognized in the related art, so as to eliminate the time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

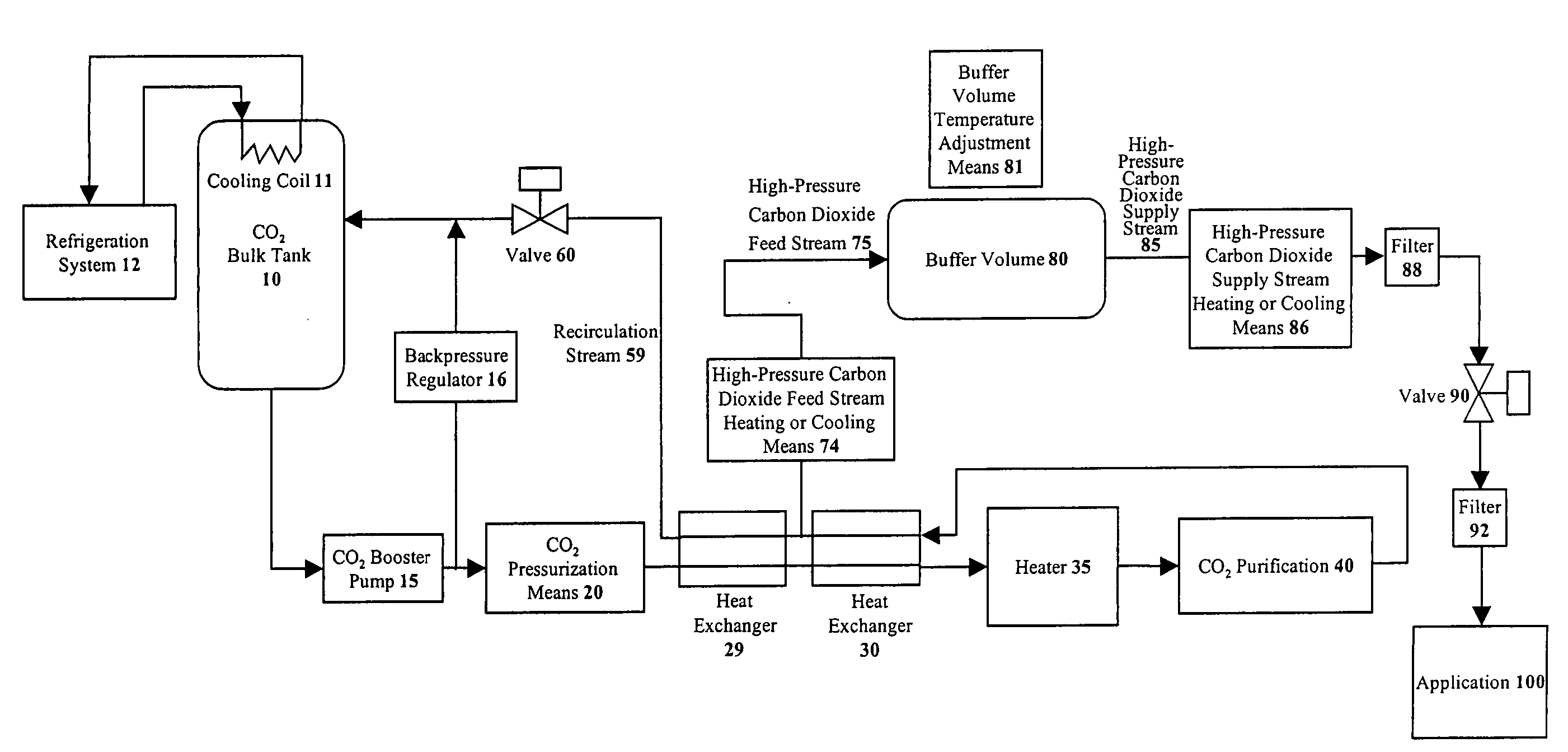

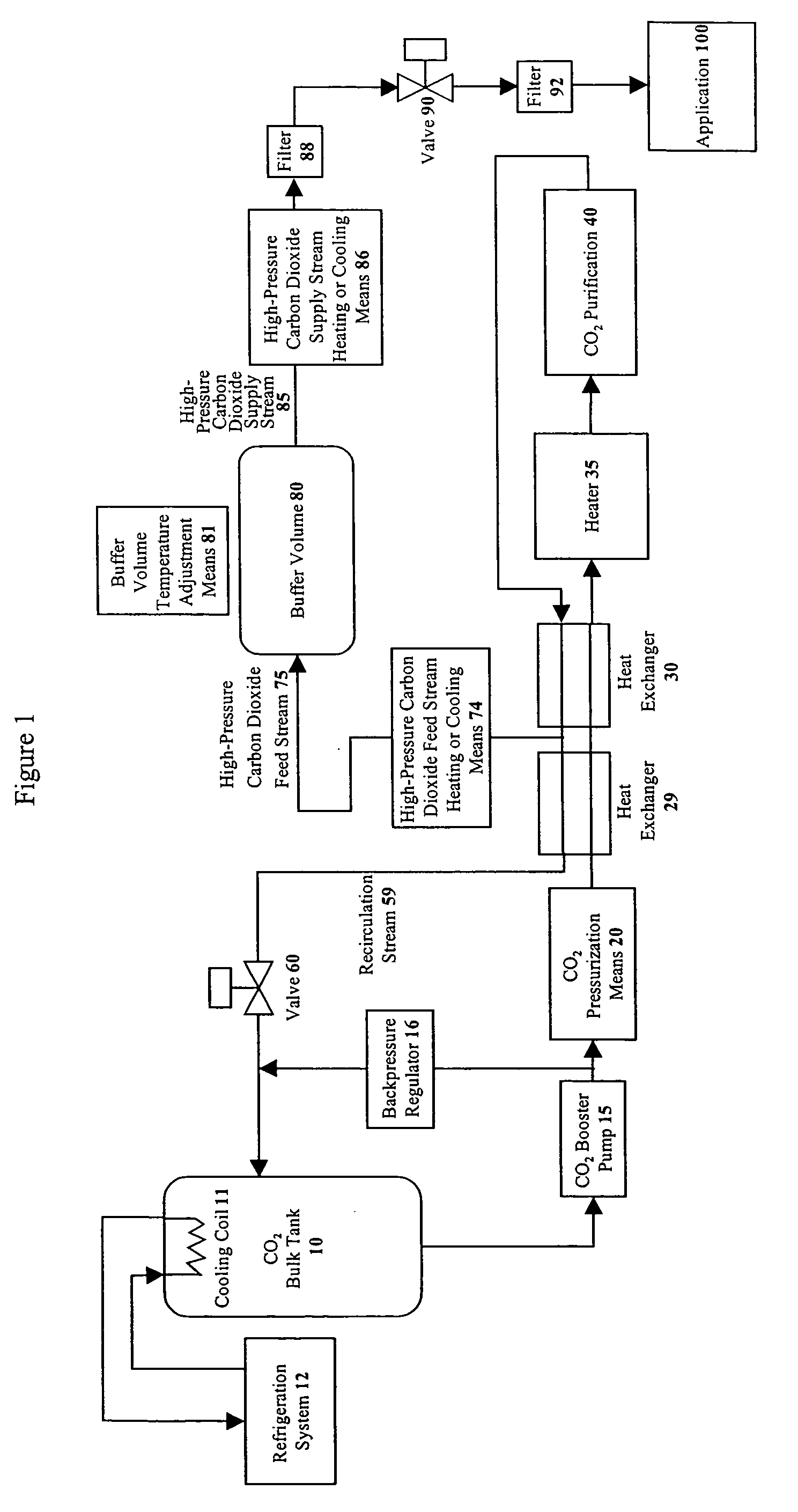

[0027] The manufacturing of integrated circuit devices requires numerous complicated steps necessary to form various features onto the wafer substrate. Some of the steps include cleaning the substrate with high-pressure carbon dioxide. As utilized herein the term “high-pressure carbon dioxide” refers to carbon dioxide at a pressure greater than its critical pressure of 1060 psig. In the event that the temperature associated with the carbon dioxide is below its critical temperature of 88° F. and is at high pressure it will be understood that the fluid is in liquid phase. On the other hand, if the temperature associated with the carbon dioxide is greater than 88° F., the fluid will be in supercritical phase. Therefore, at above 1060 psig, the carbon dioxide is in one phase only, whether it be liquid or supercritical (i.e. no discontinuous phase transition).

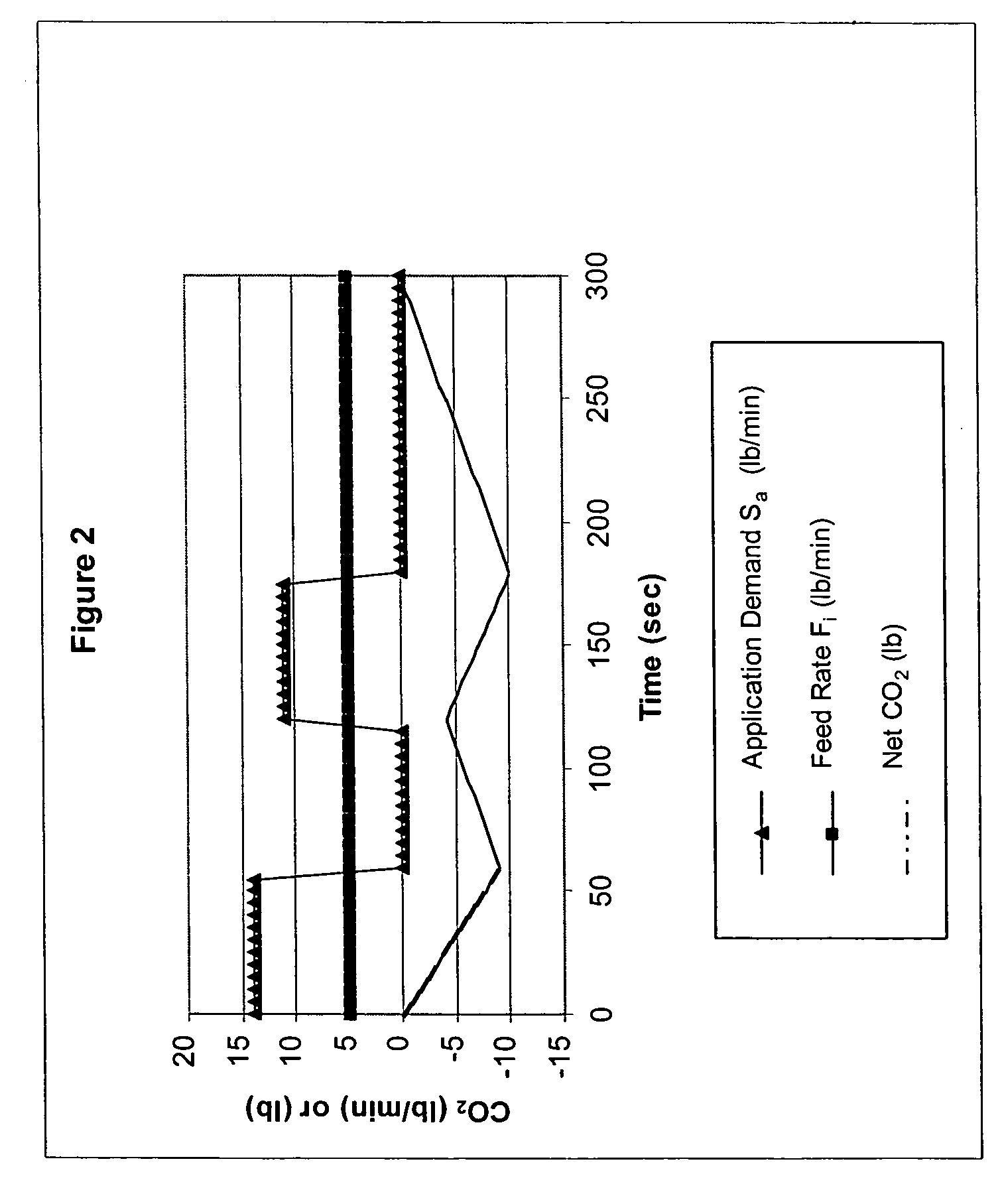

[0028] The semiconductor cleaning process of the present invention provide an effective means of supplying high-pressure carbon d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical pressure | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com