Lateral boring system

a technology of lateral boring and lateral borehole, which is applied in the direction of drilling pipes, drilling rods, directional drilling, etc., can solve the problems of low drill bit power, unable to allow the flexible shaft to extend deeper, and the blade to penetrate through, etc., to achieve the effect of simple and effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

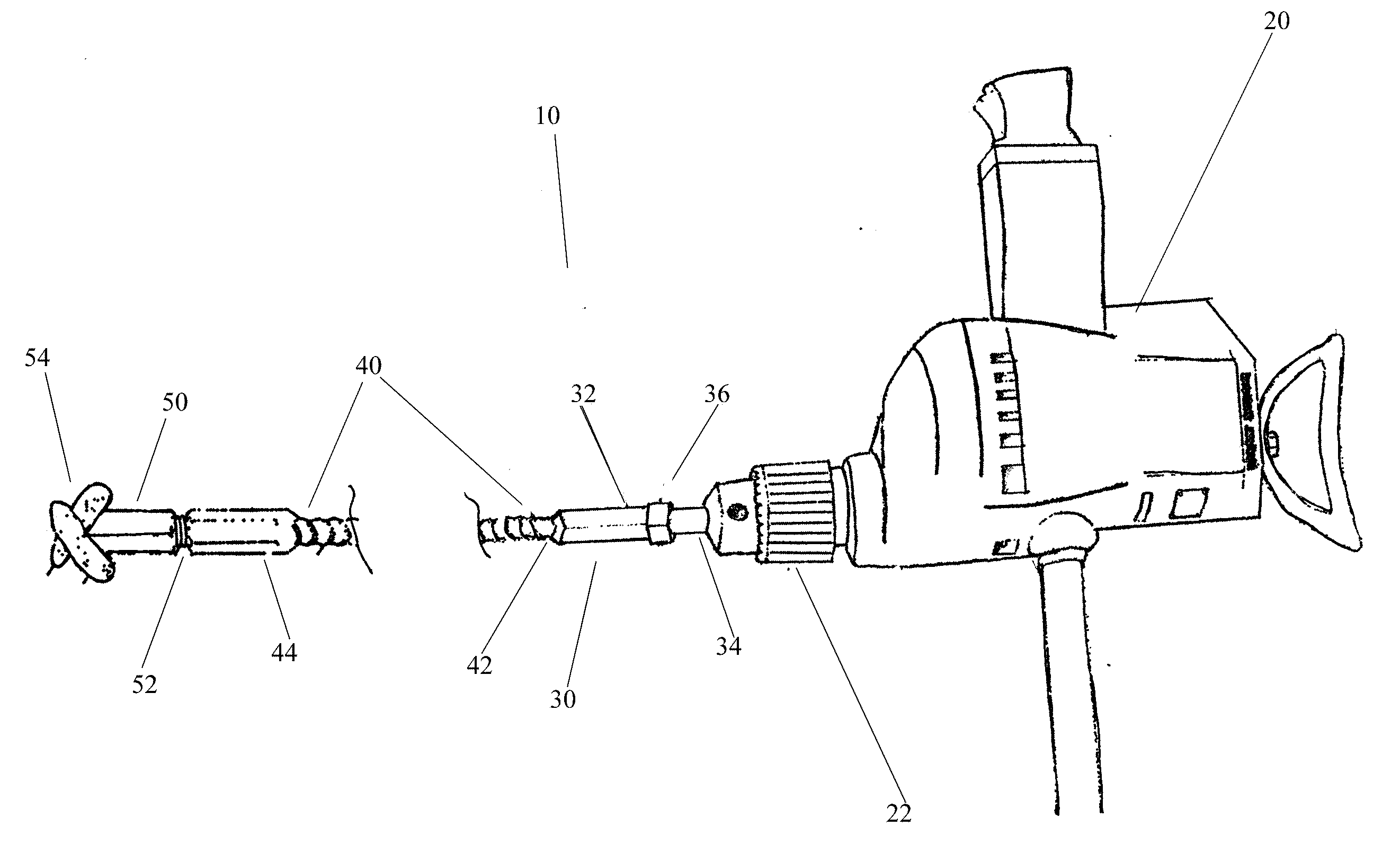

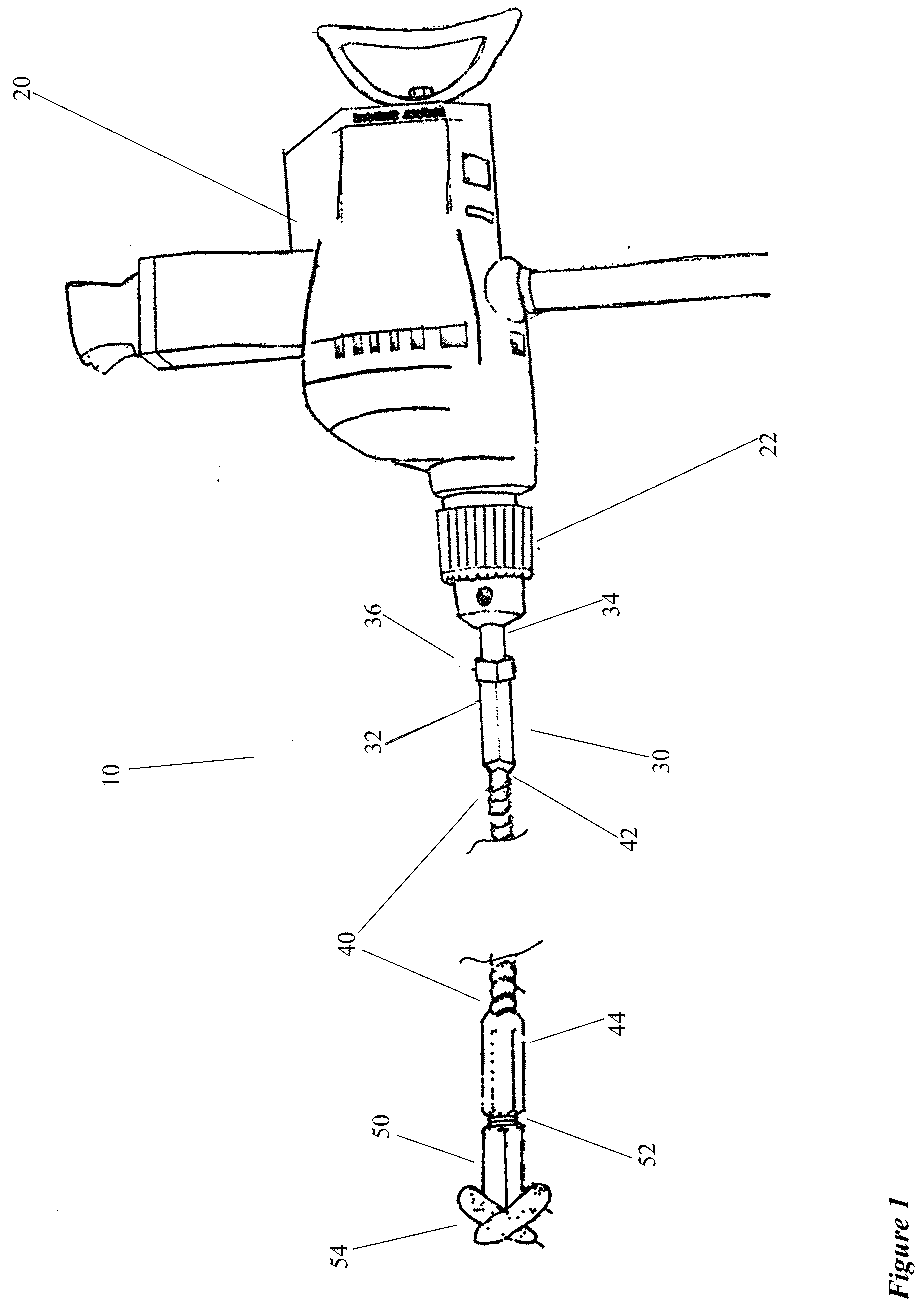

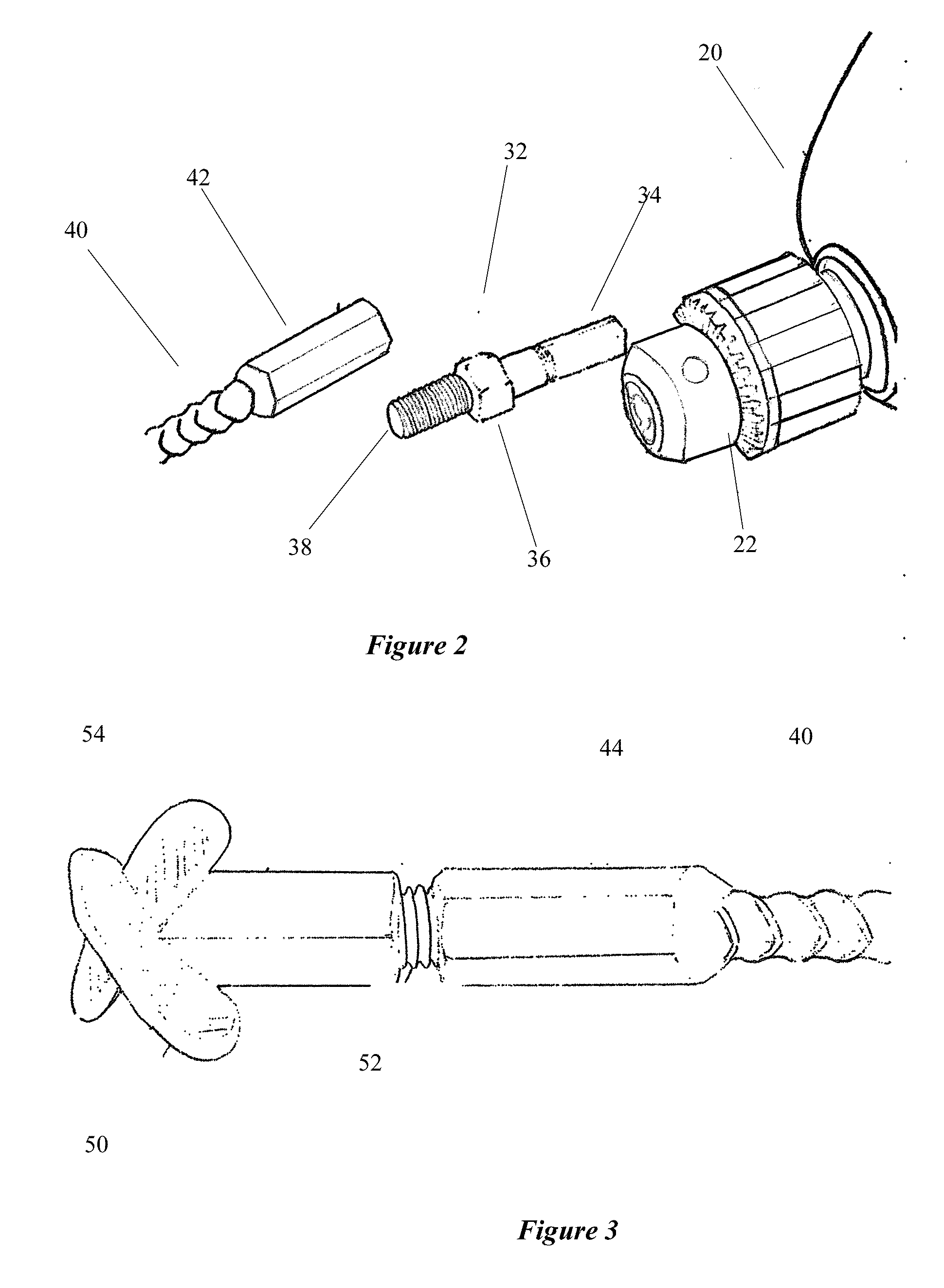

[0015] The present invention provides a tool capable of laterally boring for the placement of underground cables, wires, pipe and other equipment. Referring in more detail to the drawings, as shown in FIGS. 1-5, a preferred embodiment of the present invention is described. It is to be expressly understood that this exemplary embodiment is provided for descriptive purposes only and is not meant to unduly limit the scope of the present inventive concept. Other embodiments, and variations of the hand-held drive assembly or flexible shaft of the present invention are considered within the present inventive concept as set forth in the claims herein. For explanatory purposes only, the apparatus of the preferred embodiments are discussed primarily for the purposes of understanding the method of underground boring. It is to be expressly understood that other boring equipment are contemplated for use with the present invention as well.

[0016] A preferred embodiment of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com