Roll-forming machine for gutter cap and method for making same

a technology of gutter cap and rolling machine, which is applied in the direction of roof covering, roof construction, roofs, etc., can solve the problems of affecting the efficiency of rain gutters, affecting the flow of water, and accumulating along the wire mesh would then present an emergent obstacle, so as to increase the flow of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

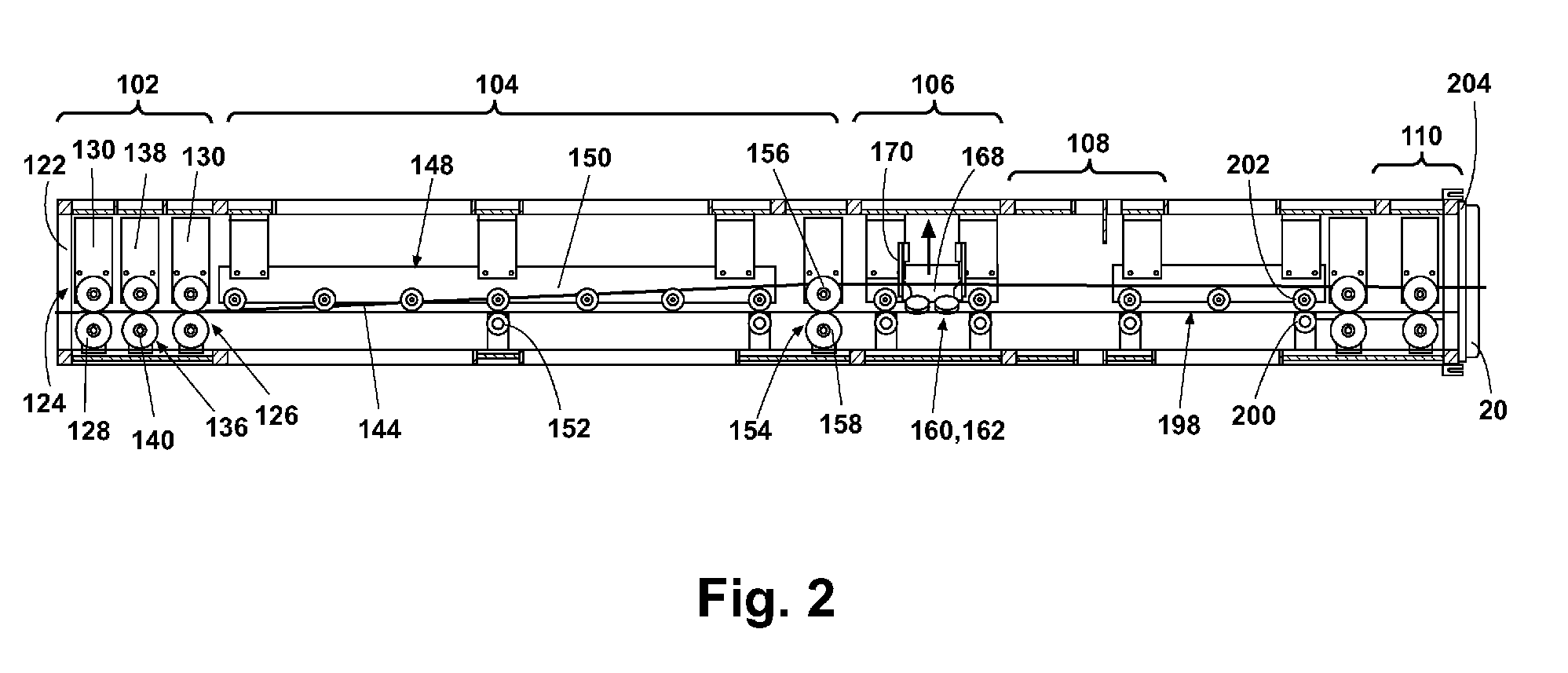

[0036] The instant invention include a novel cap for a rain gutter intended to exclude debris, yet capture water runoff from the roof structures of buildings and the like. In combination with the novel gutter cap is a novel and unique bracket used to mount a rain gutter to a fascia board of the structure. In addition, a unique method and machine are disclosed for making this inventive gutter cap.

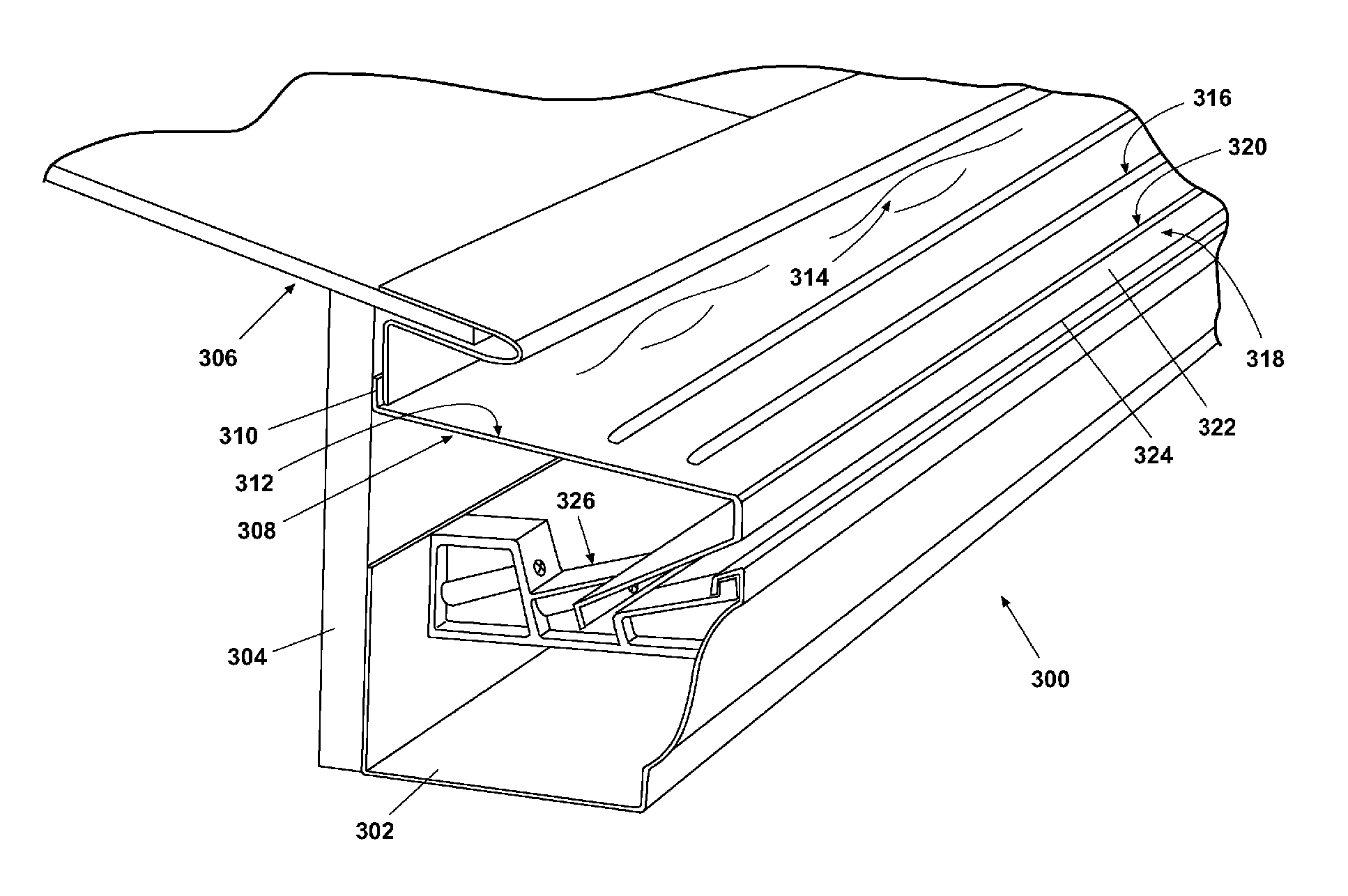

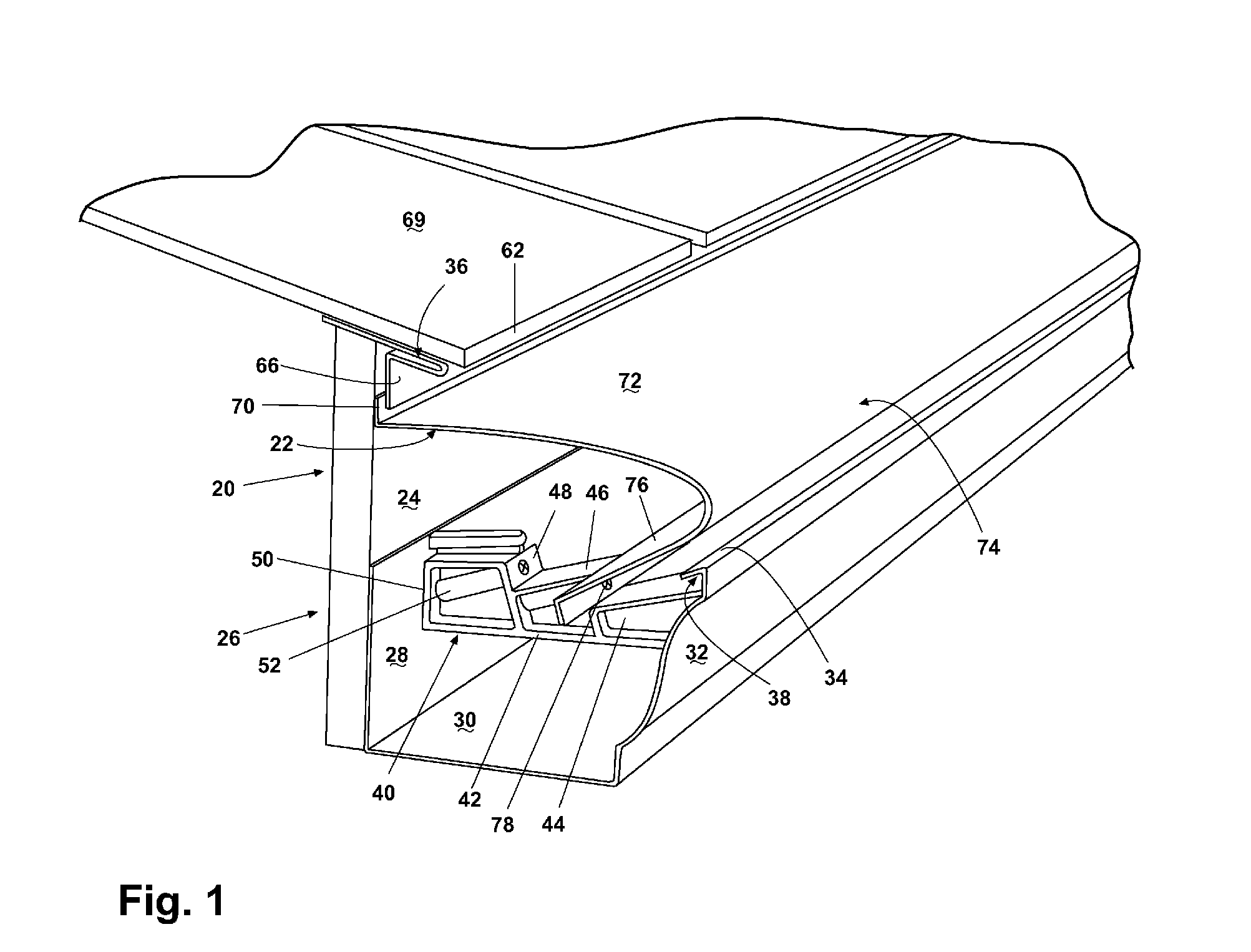

[0037]FIG. 1 generally illustrates an embodiment of a rain gutter assembly 20 including a rain gutter 22 having a predetermined profile and mounted to a fascia board 24 of a structure or building 26. In this particular case, the rain gutter 22 includes an inside vertical flange 28 integral with a bottom flange 30 extending generally perpendicular there from. Extending upward from the distal edge of the flange 30 is an outer flange 32 often shaped into a decorative profile. In the rain gutter 22 shown, the outer flange 32 terminates with a capture surface 34 inclined in towards the interior ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com