Purification of impure oil by centrifugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

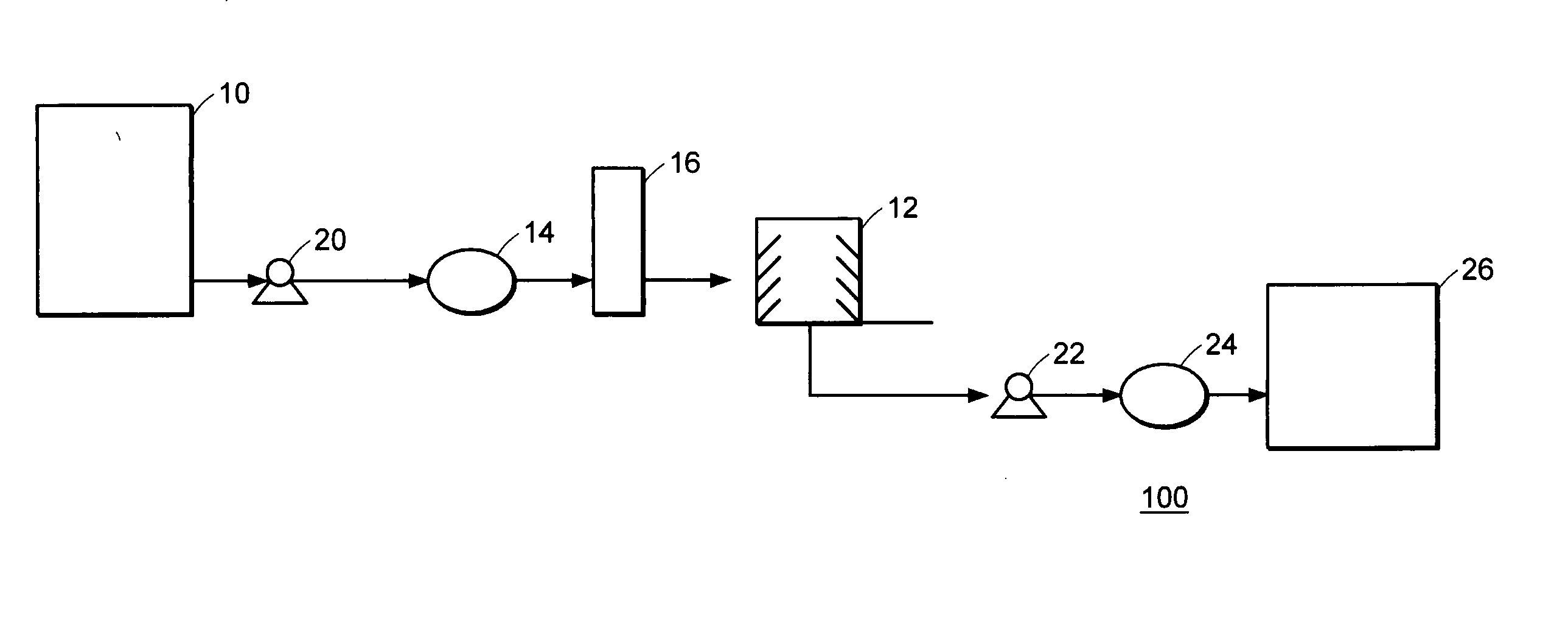

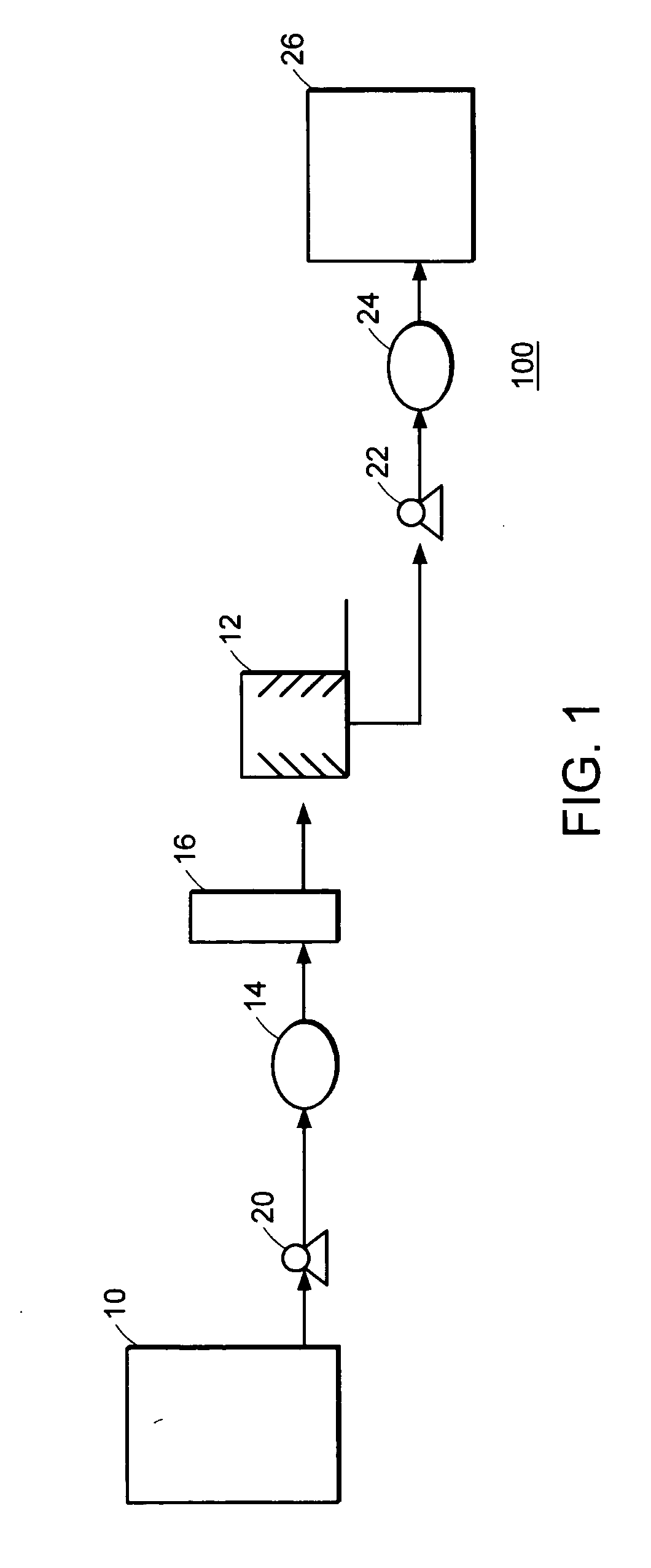

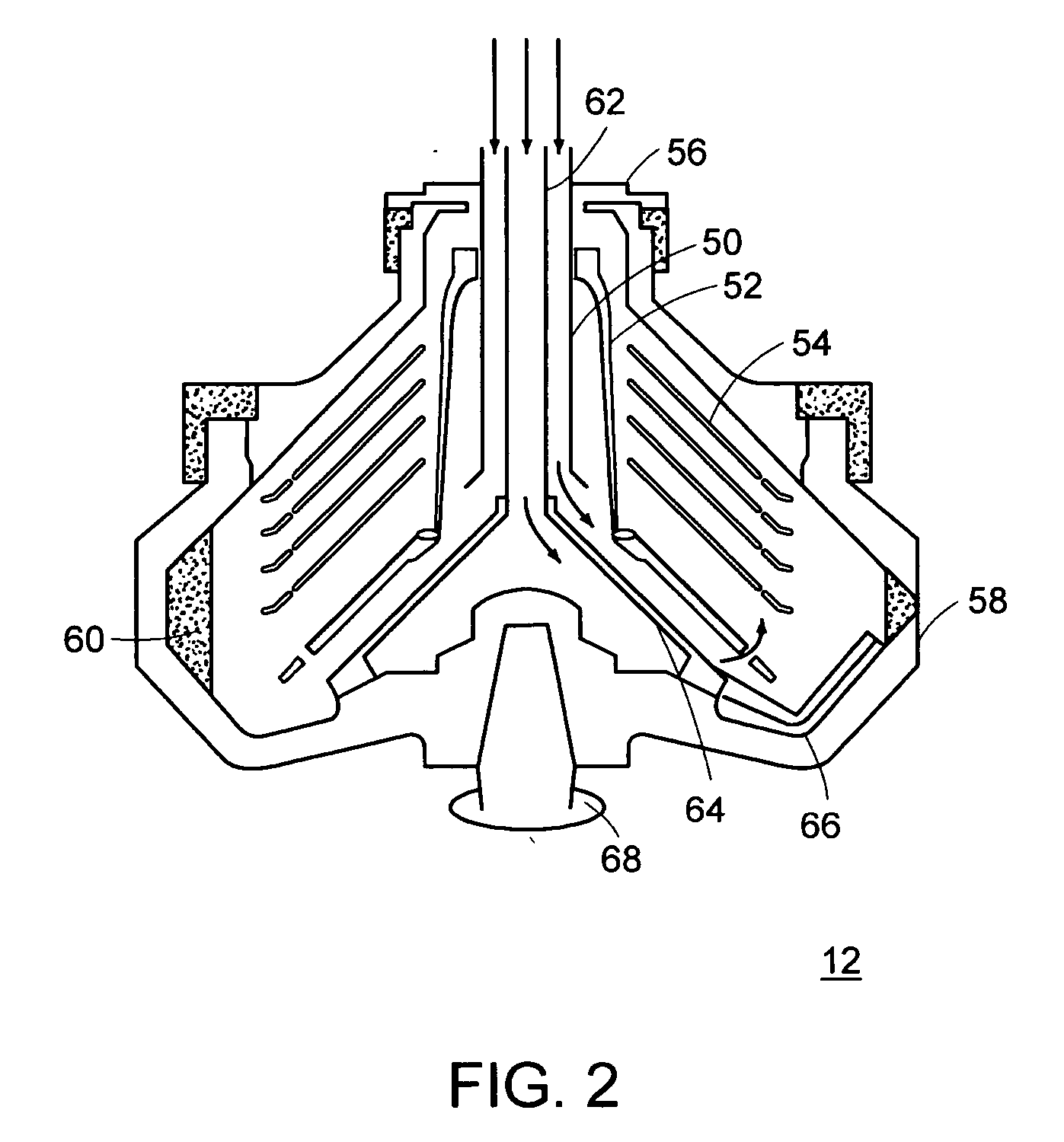

[0015] The present invention relates to methods for refining and / or purifying an impure oil (e.g., crude oil or clarified oil) so that better quality end products, such as gasoline and heating oil, can be made. The present invention involves removing certain impurities that can cause damage to equipment that uses the oil. The methods described herein allow for quick and efficient purification of large quantities of oil, and include subjecting oil in need of purification (e.g., oil having certain impurities) to a disk stack centrifuge at high flow rates to result in a purified oil.

[0016] Purifying oil or refining oil refers to a process of decreasing, removing or separating away one or more impurities from the oil. The phrases, “purifying oil” or “refining oil” are used interchangeably herein. The process of the present invention purifies the oil so that the impurity content, inorganic materials content or ash content is decreased or lessened, as compared to the respective content p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com