Gas burner head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

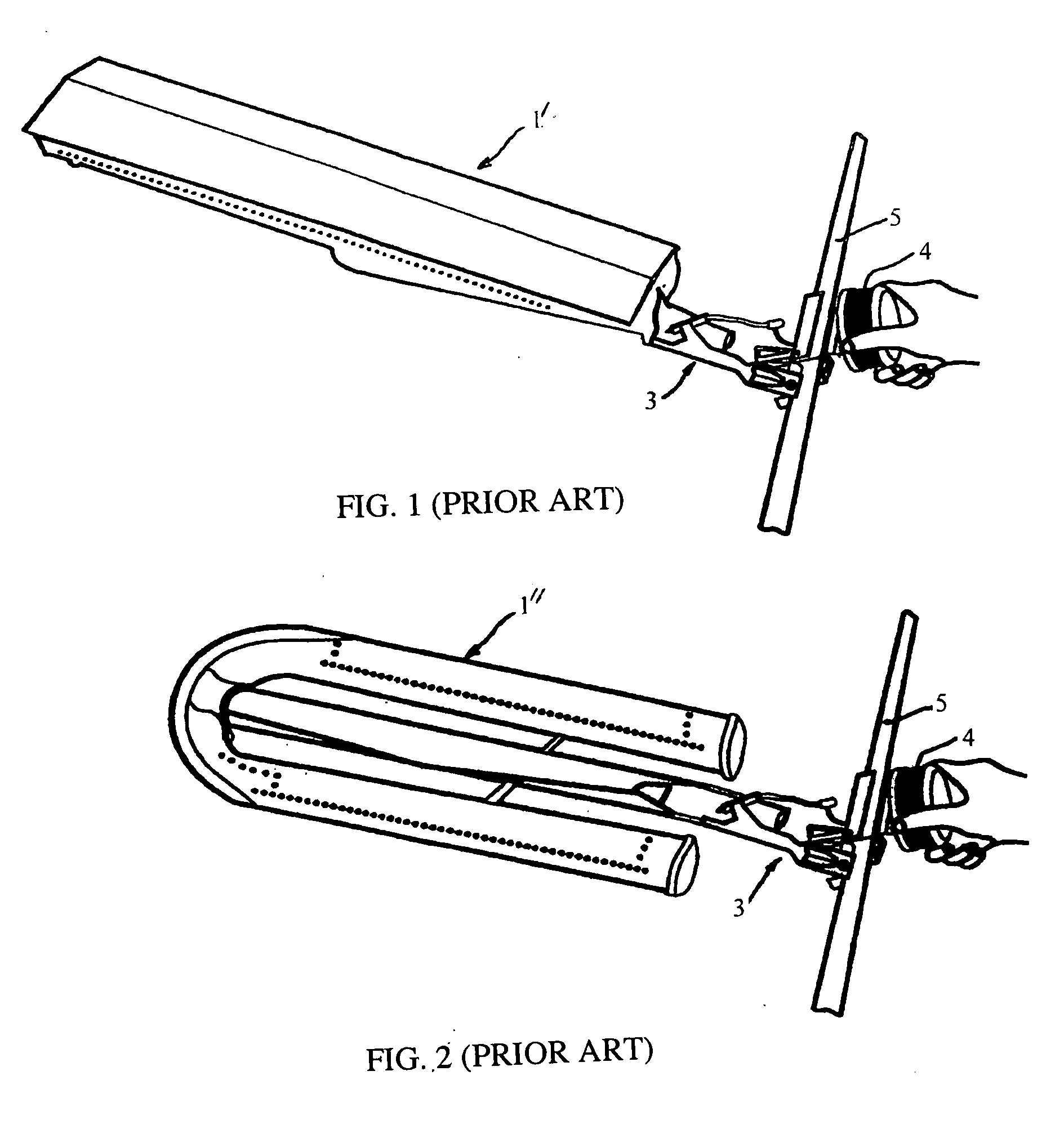

[0021]FIG. 1 and FIG. 2 are two exemplary conventional gas burner heads 1′ and 1″. The burning surfaces are at a level that is almost equal to the level positioned by the igniter and gas nozzle 3 disposed on a valve module 4, which is mounted on the oven body 5. The igniter assembly and the valve assembly are standardized products uniformly produced by manufacturers. These tubing-type conventional burner heads 1′ and 1″ are only suitable for standard gas burners.

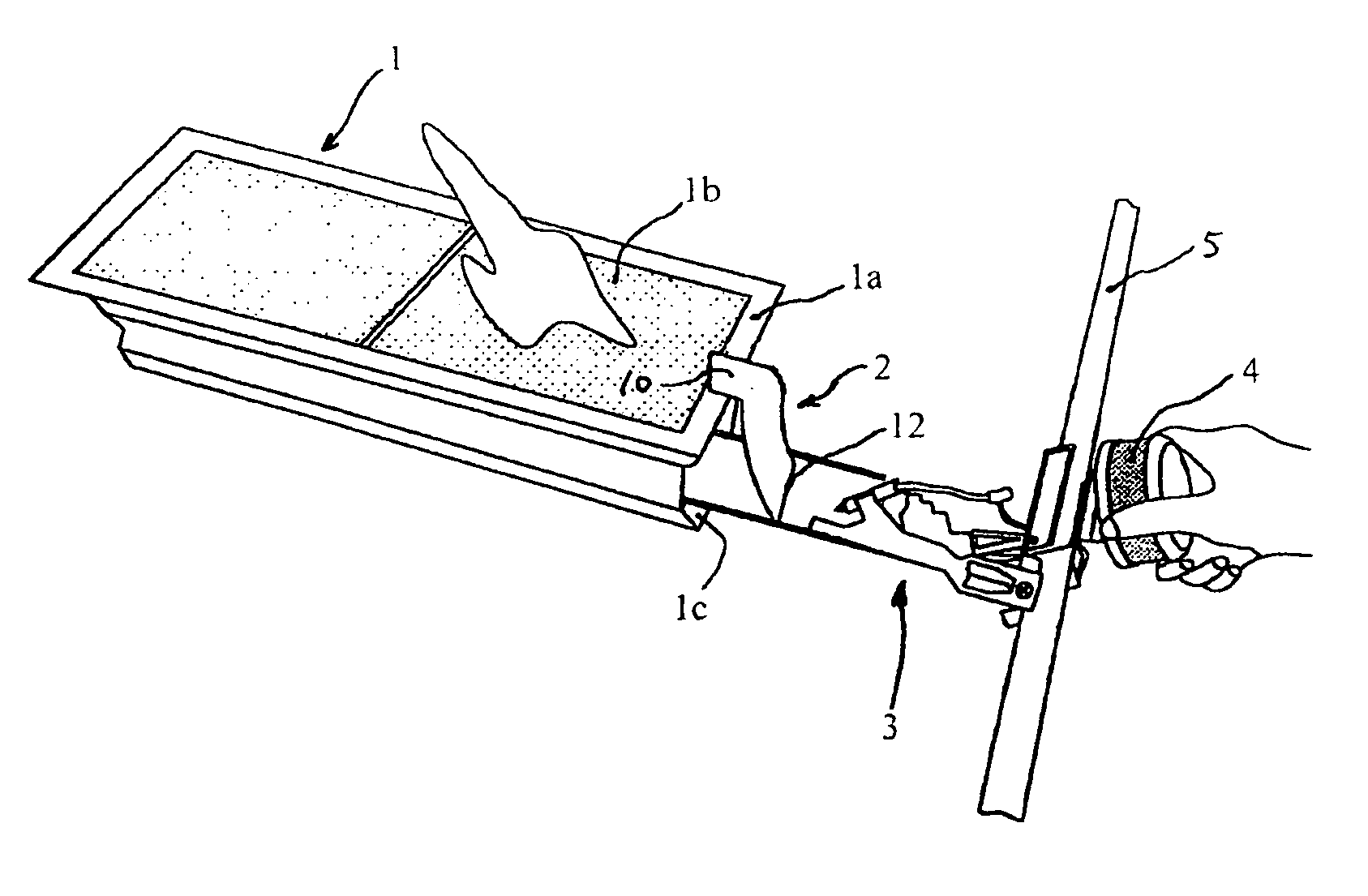

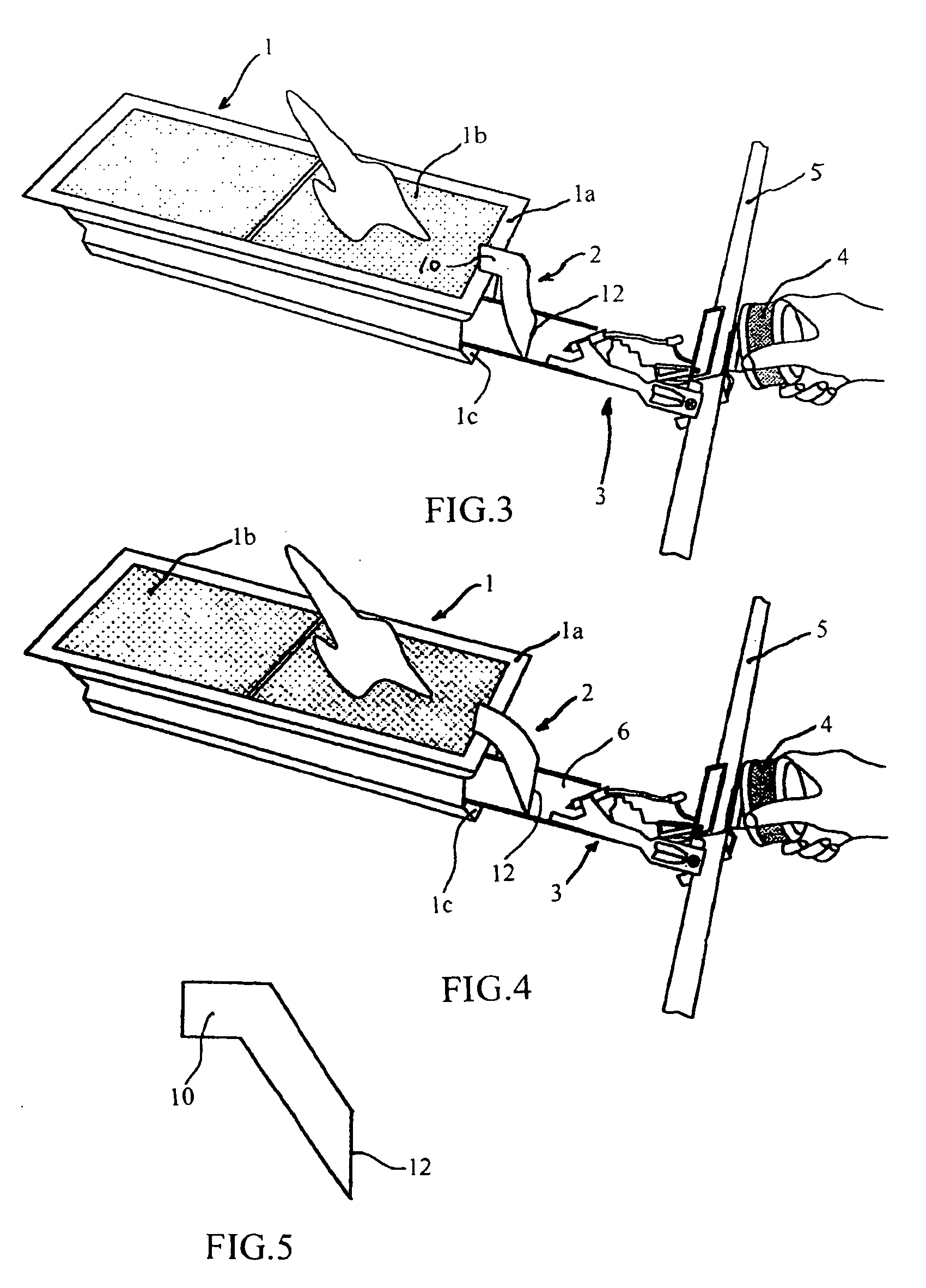

[0022]FIG. 3 and FIG. 4 show two exemplary embodiments of a gas burner head 1 according to the present invention. The burner head assembly 1 can readily replace the conventional burner head and accommodate the height difference between the burning surface and the igniter in standard gas ovens, achieving the goal of enabling a standard type gas oven to have multiple uses. A standard type gas oven installed with the gas burner head assembly 1 can be easily and conveniently switched from a general-purpose oven to a special bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com