Electric pump and modularized fuel supply system with such electric pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first representative embodiment

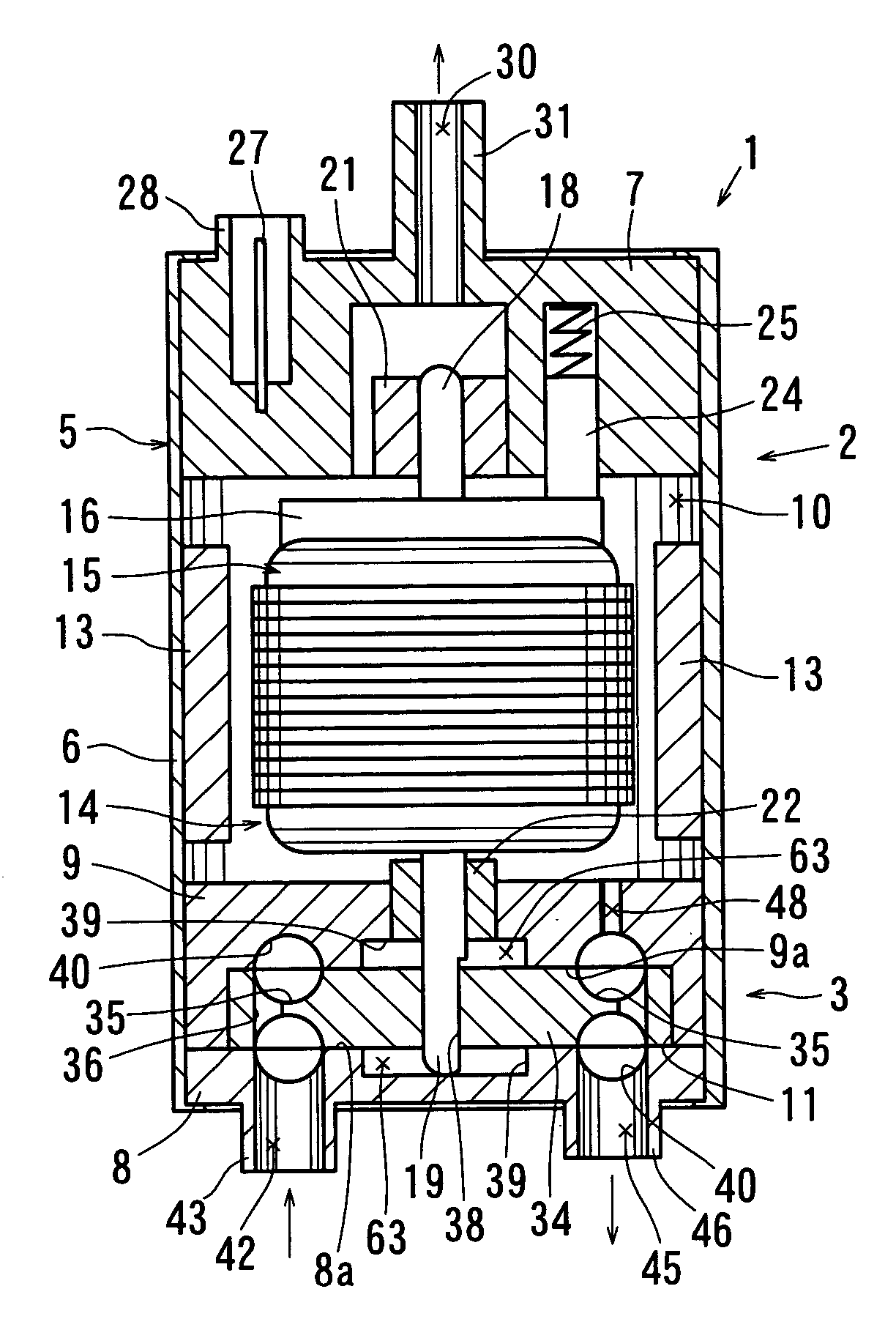

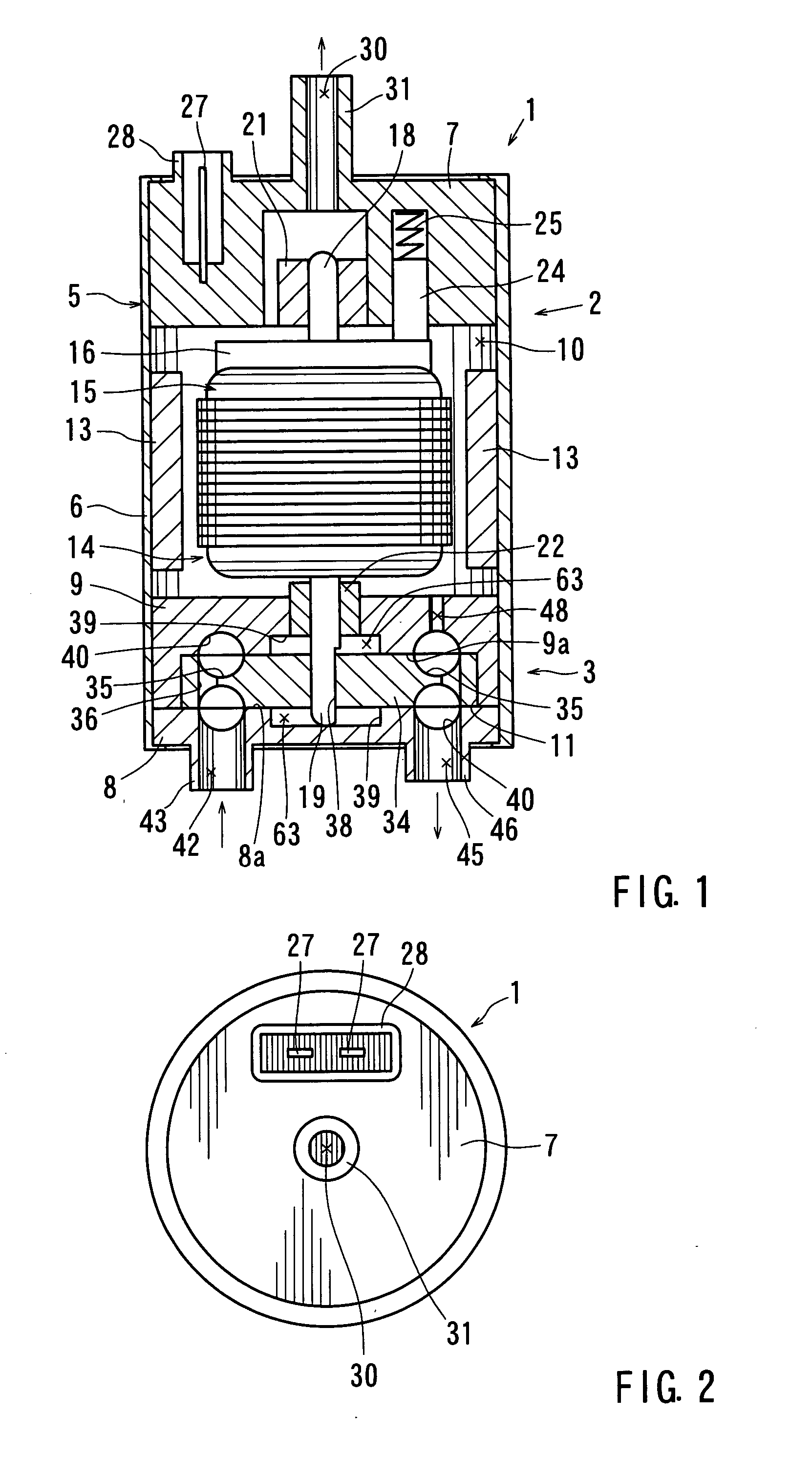

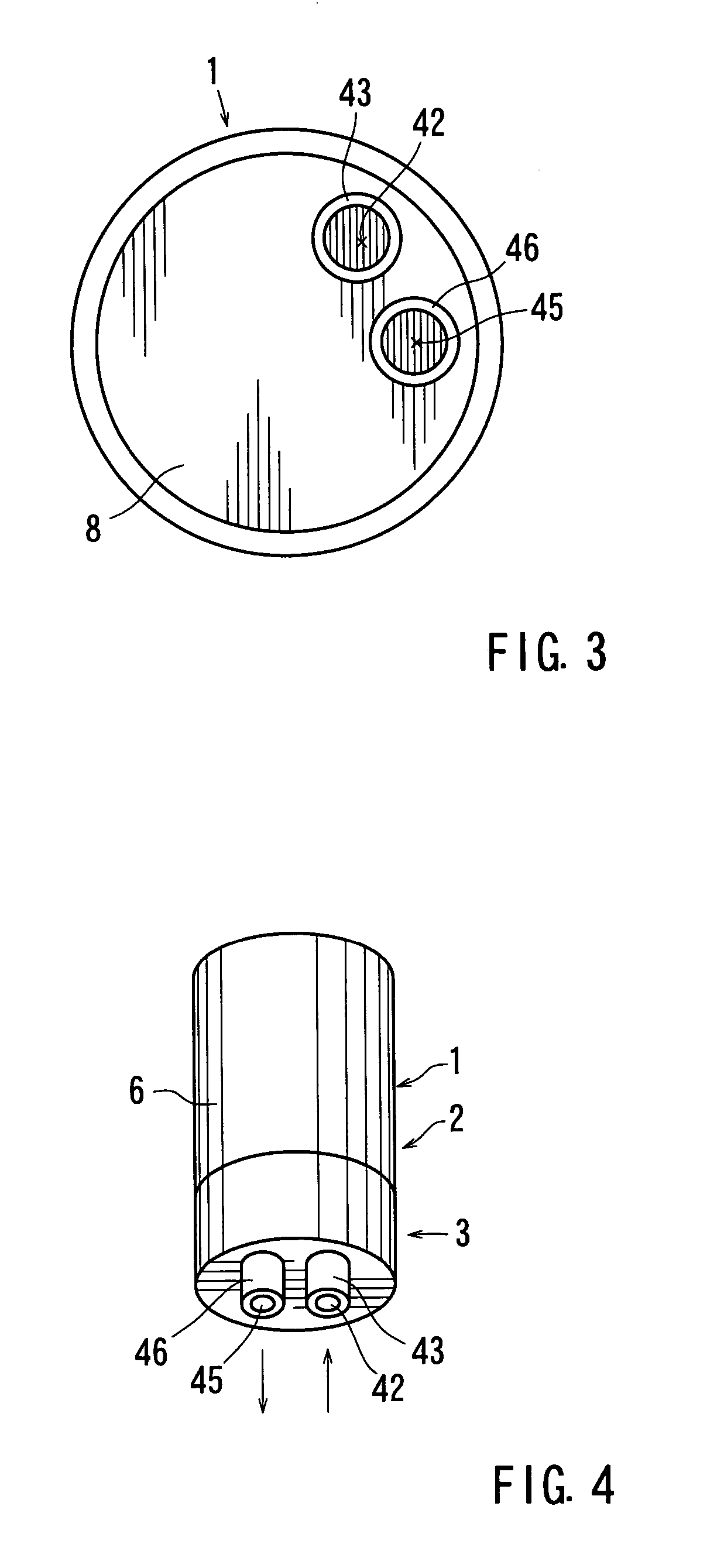

[0081] Turning now to the drawings, a fuel pump according to a first representative embodiment (hereinafter referred to as a “first representative fuel pump”) is shown in FIGS. 1 to 7.

[0082] Referring to FIG. 1, a fuel pump 1 is integrally provided with a motor section 2 and a pump section 3. The pump section 3 is disposed at one end of the motor section 2 (the lower end in FIG. 1). The outer shell of the fuel pump 1 is a pump casing 5, which includes a generally tubular shell 6, a motor cover 7 sealing one end of the tubular shell (the upper end in FIG. 1), a pump cover 8 sealing the other end of the tubular shell (the lower end in FIG. 1), and a pump housing 9 overlayingly provided on the pump cover 8 to partition the inside area of the pump casing 5 into a motor compartment 10 and a pump compartment 11. It is to be noted that the motor cover 7 is also referred to herein as an “end cap member of the motor section.” Similarly, the pump cover 8 is also referred to herein as an “end...

second representative embodiment

[0097] Referring to FIG. 8, a fuel pump according to a second representative embodiment (hereinafter referred to as a “second representative fuel pump”) will be described. Since the second representative fuel pump is a modification of the first representative fuel pump, the description will be made only for the features that are different from the first representative fuel pump. As shown in FIG. 8, the second representative fuel pump 1 is modified in the shaft structure of the pump side of the armature 14 and the connection structure between the armature 14 and the impeller 34. As clearly understood when comparing with FIG. 5 of the first representative fuel pump 1, the pump side or the lower end of the shaft 18 has a generally round-bar-shaped shaft portion 18a, without a connecting portion 19 (see FIG. 5). The lower shaft portion 18a of the shaft 18 is rotatably supported by a bearing 50, which is mounted in the supporting hole 49 formed on the bottom surface of the pump cover rec...

third representative embodiment

[0108] Referring to FIGS. 9 and 10, a fuel pump according to a third representative embodiment (hereinafter referred to as a “third representative pump”) will be described. The third representative fuel pump is a modification of the first representative fuel pump. As shown in FIG. 9, the third representative fuel pump 1 is modified in that the second outlet port 30, defined by the second outlet tube 31 of the motor cover 7 of the first representative fuel pump 1, is provided with a check valve or a ball member 67. The lower portion of the second outlet port 30 within the second outlet tube 31 is provided with a valve seat 68, which is closed or opened by the ball member 67. On the other hand, the upper portion of the second outlet port 30 within the second outlet tube 31 is provided with a ball stopper 69, for example, formed in a C-shaped ring. The ball stopper 69 prevents the ball member 67 from ejecting out of the second outlet tube 31. When a fuel flows from the motor compartmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com