Linear pump with vibration isolation

a linear, vibration isolation technology, applied in the field of pumps, can solve the problems of increasing bulk, adding hardware and cost, and rapid movement of single pistons, and achieve the effect of improving the isolation of the pump body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

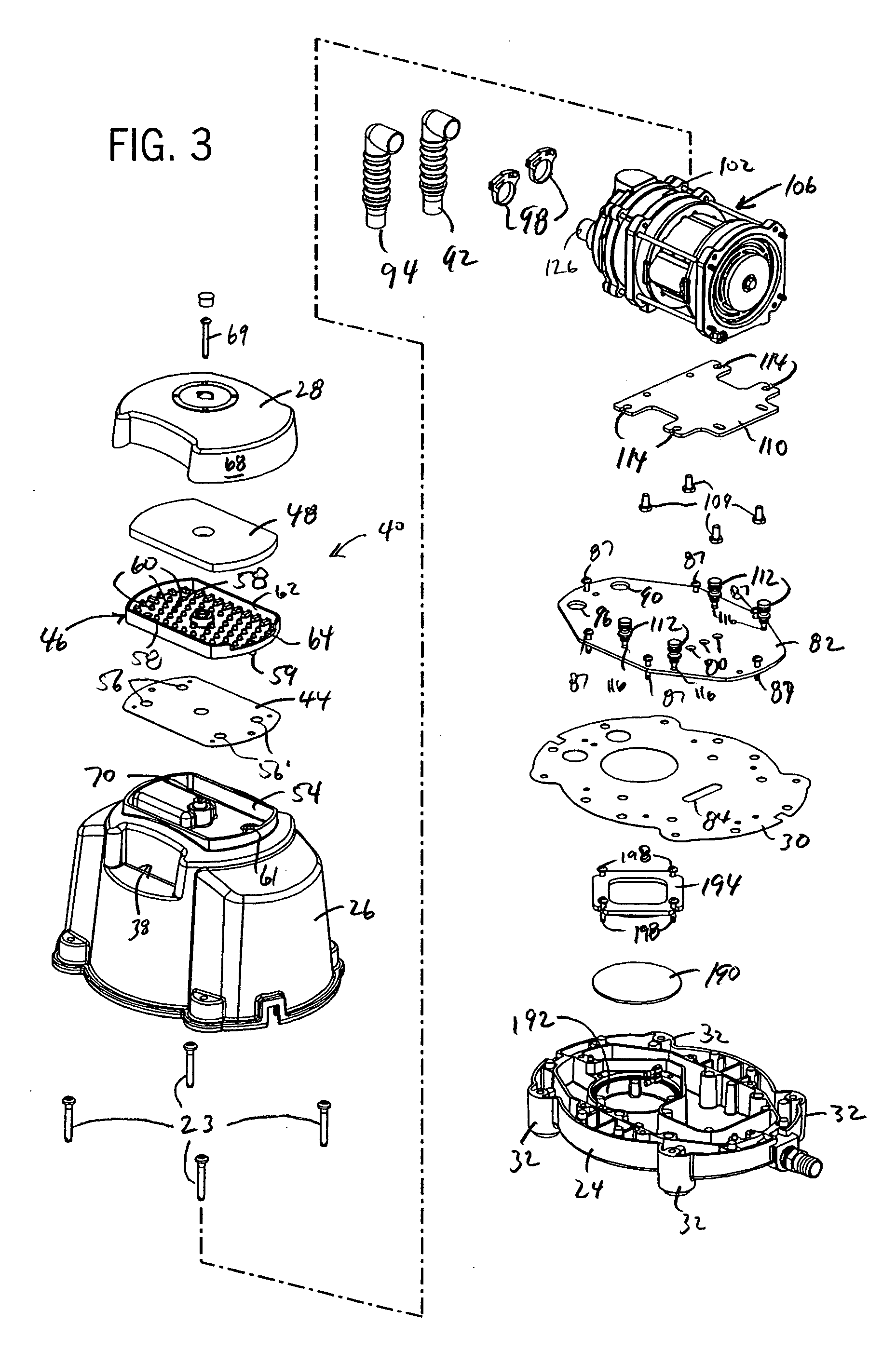

[0034] The present invention provides an axial or linear piston pump. The term pump used herein includes a device for providing either positive or negative pressure, and thus either acting as a vacuum pump or a compressor. The pump has a compact form factor, with a preferred operating range of 2-30 psi depending upon the application (however, the pump could be designed to operate at other pressures) with low external vibration and noise and less sensitivity to pump attachments (lines, hoses, tubing, etc.) downstream from the outlet.

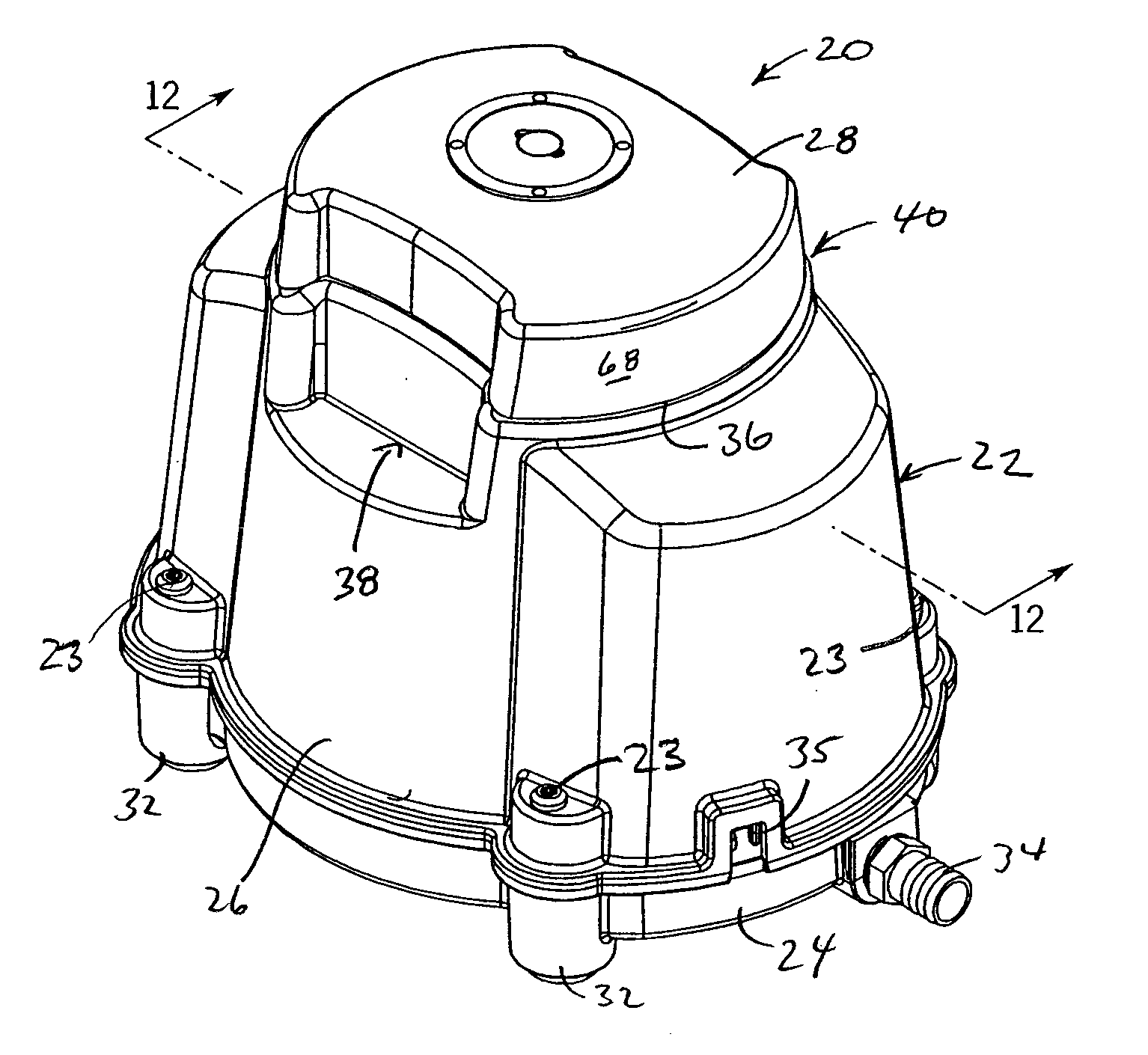

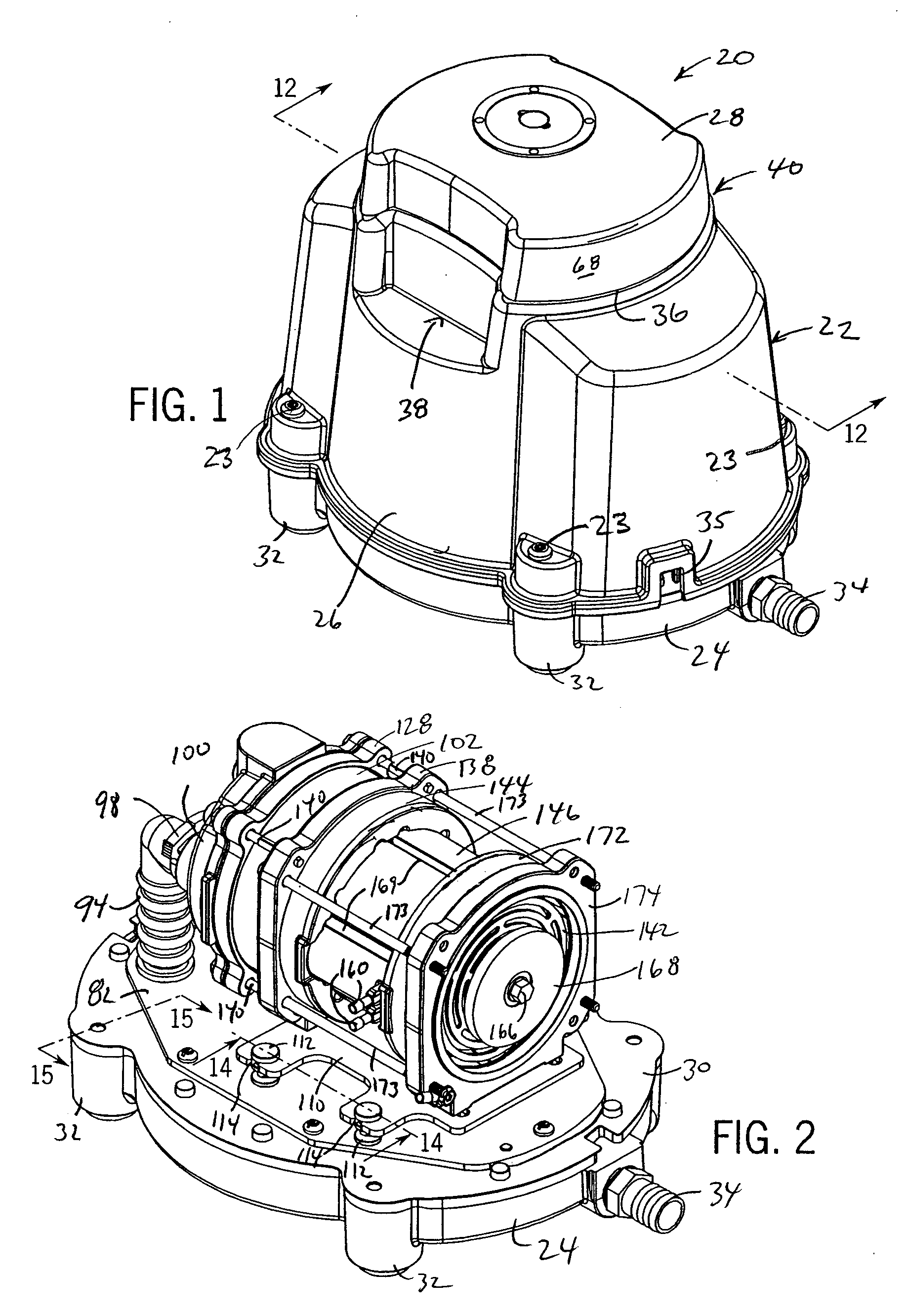

[0035] Referring to FIGS. 1-3, the pump, generally referred to in the drawings by reference number 20, has a compact housing 22 including a base 24, a shroud 26 and a top cover 28. The shroud 26 is bolted to the base 24 (via bolts 23), with a gasket 30 therebetween (see FIG. 15), and the cover 28 is bolted (via bolt 69) to the shroud 26. The base has four feet 32 to support the pump 20 and provides an opening for connecting a fitting 34 (see FIG. 11). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com