Low-friction reciprocating pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

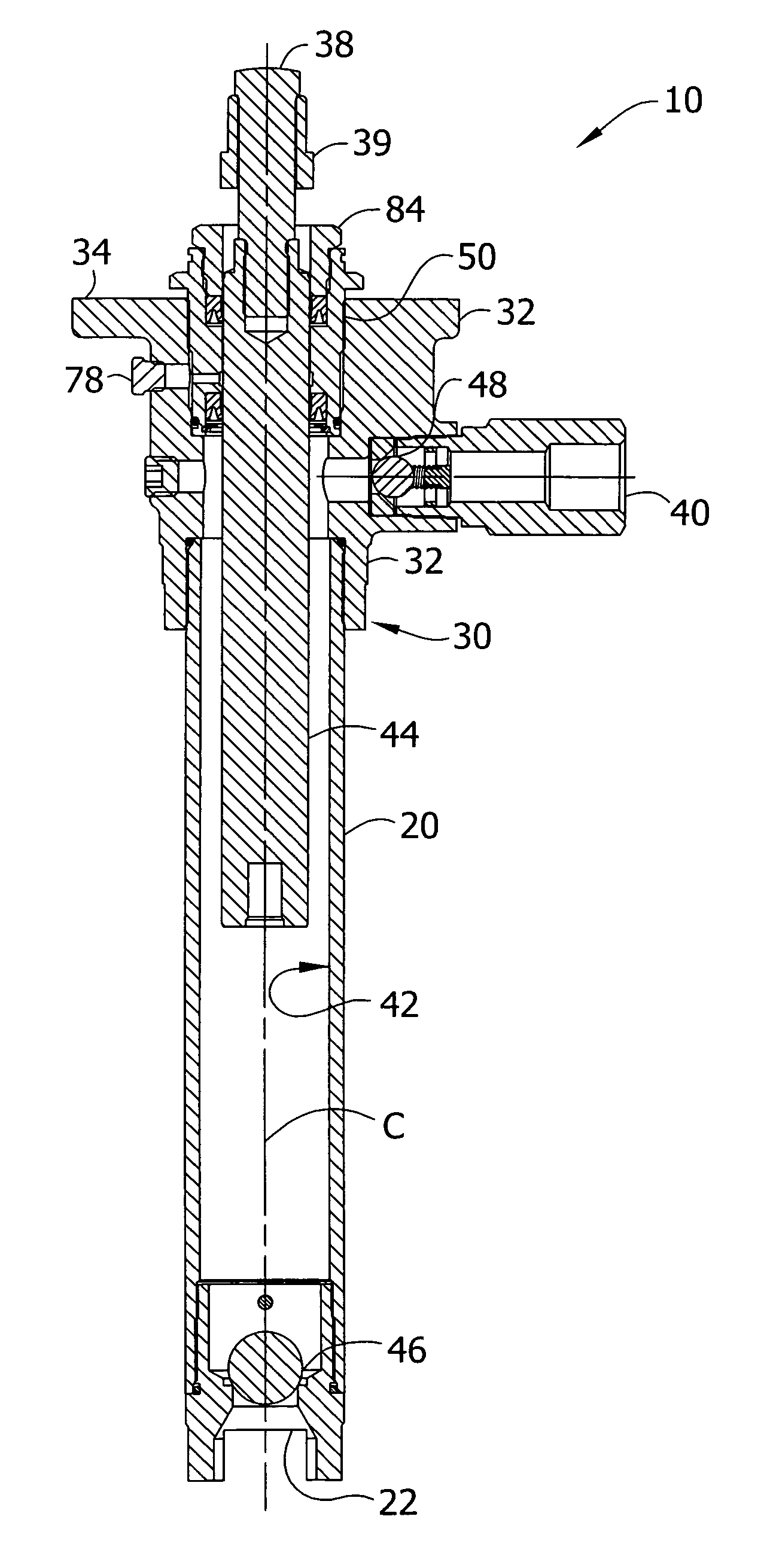

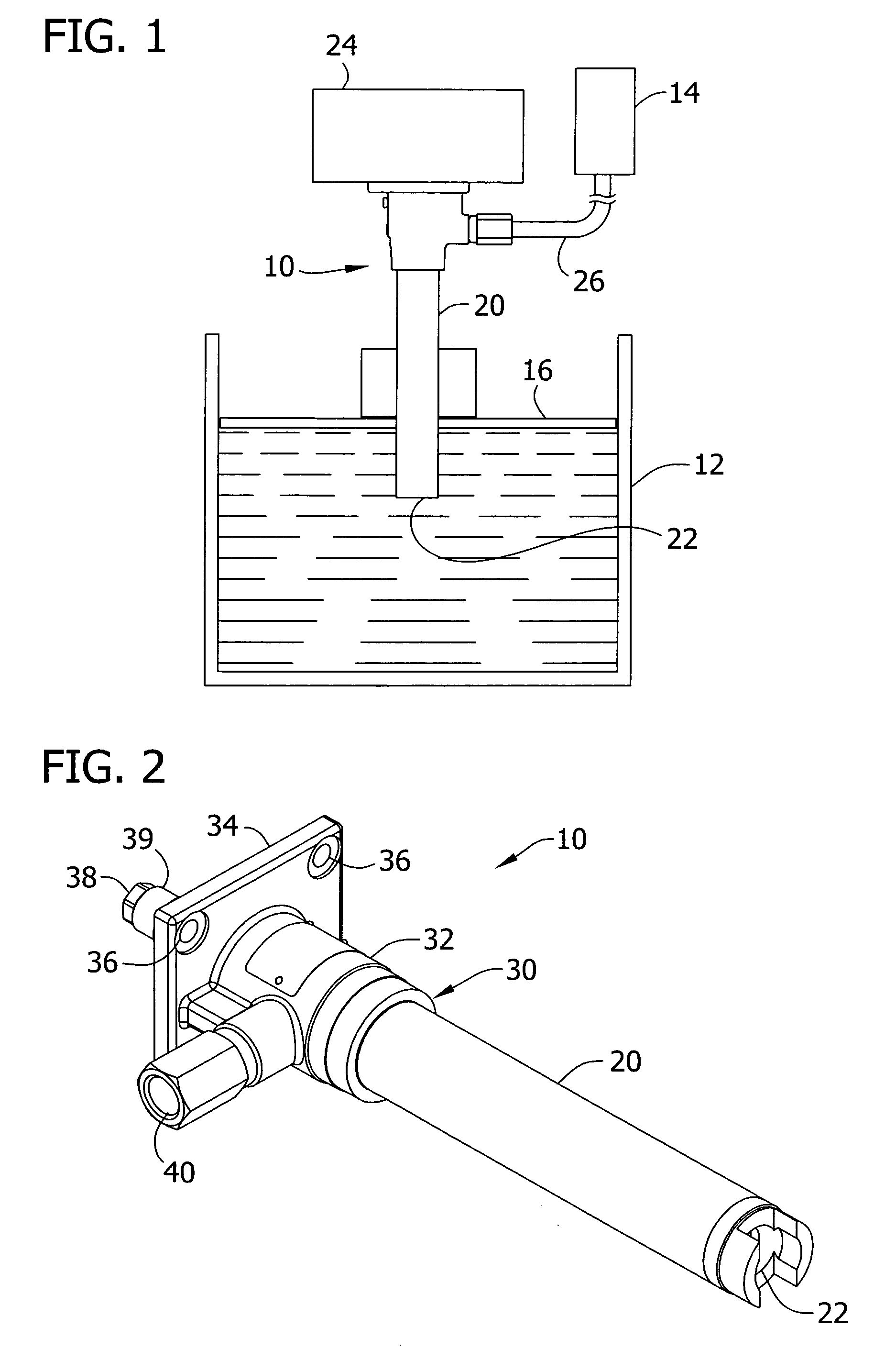

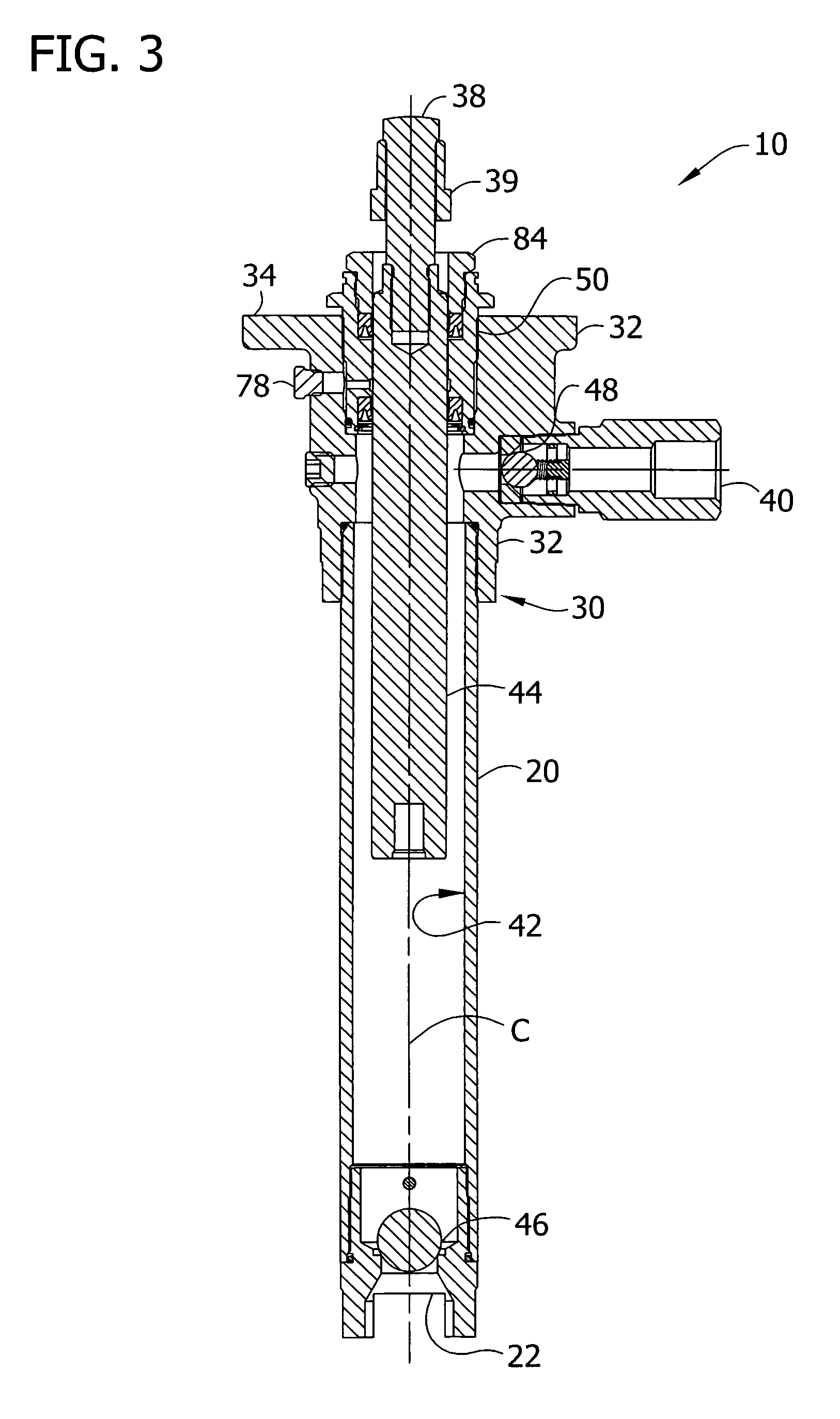

[0016] Referring now to the drawings and in particular to FIG. 1, a pump according to the present invention for delivering fluid to a device requiring fluid is indicated generally at 10. The pump 10 may be used, for example, in pumping ink from a supply container 12 (e.g., a drum) to fountains of a printing press 14. In one embodiment, the pump 10 is supported upon a follower plate 16 near the upper surface of fluid in the container 12. The plate 16 and pump 10 move downward in the container 12 as fluid is removed and the elevation of the upper surface of fluid is lowered. The pump 10 has a cylinder 20 which, in one embodiment, is oriented vertically with its lower end submerged in fluid of the container 12. The lower end of the cylinder has an opening comprising an inlet 22 for receiving fluid. A motor 24 is positioned above the pump for driving the pump, and a transverse outlet tube 26 extends away from the pump for delivery of fluid to the printing press 14. It is understood that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com