Urinal outlet assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

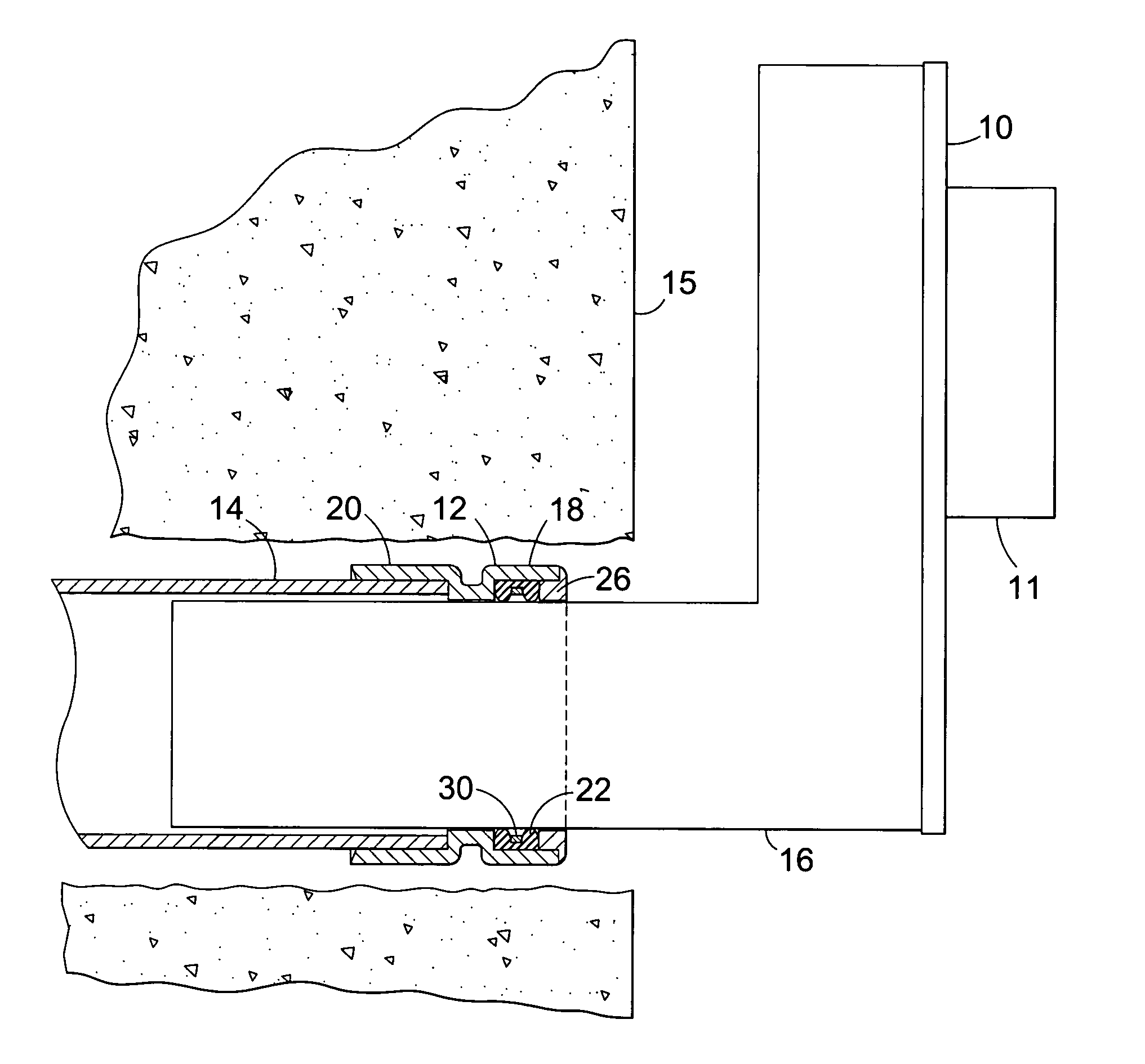

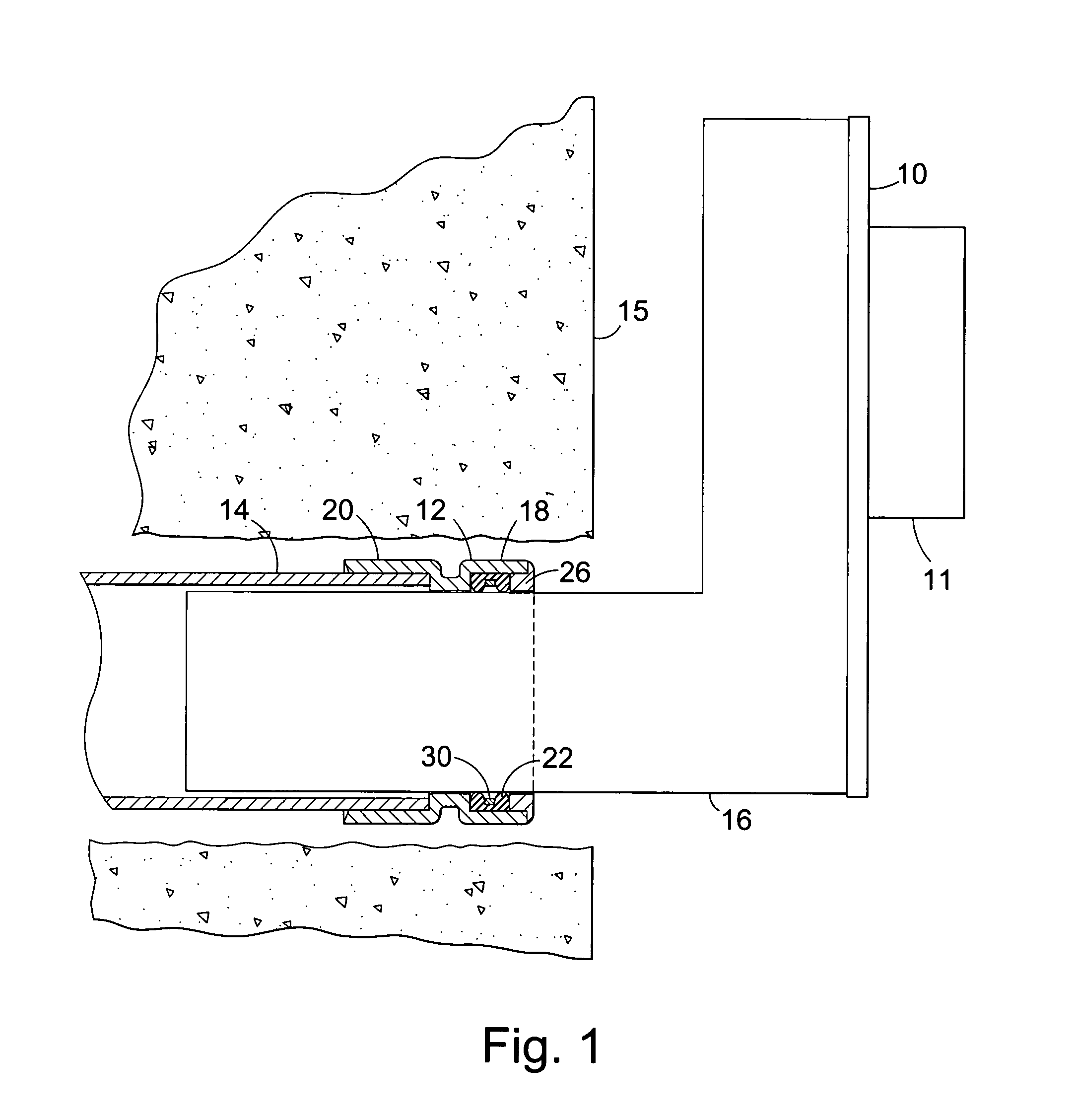

[0020] The drawing shows a part sectional view of a urinal trap assembly, including a urinal trap 10 (not shown in section). The urinal trap 10 features a tubular inlet 11 which is normally fitted with an elastomer seal (not shown) which allows the inlet 11 to be fitted over the outlet formed in the rear of a urinal (not shown). A connector 12 is provided for coupling the trap 10 to a waste pipe inlet 14. The waste pipe inlet 14 is shown located in an opening in a wall 15 which contains concealed pipe work.

[0021] The trap 10 features an outlet pipe in the form of a horizontal constant diameter tube 16.

[0022] The connector 12 is generally tubular and includes an inlet portion 18 for receiving the trap outlet pipe 16, and an outlet portion 20 for receiving the waste pipe inlet 14. In this embodiment, the connector 12 is adapted to be glued or solvent welded to the waste pipe inlet 14 to create a permanent coupling. However, the inlet portion 18 is intended to receive the trap outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com