Recirculating fluidic network and methods for using the same

a fluid network and fluid technology, applied in the field of microfluidic devices, can solve the problems of limiting the usefulness of current microfluidic devices, requiring only a minimal amount of samples, and requiring only a small amount of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

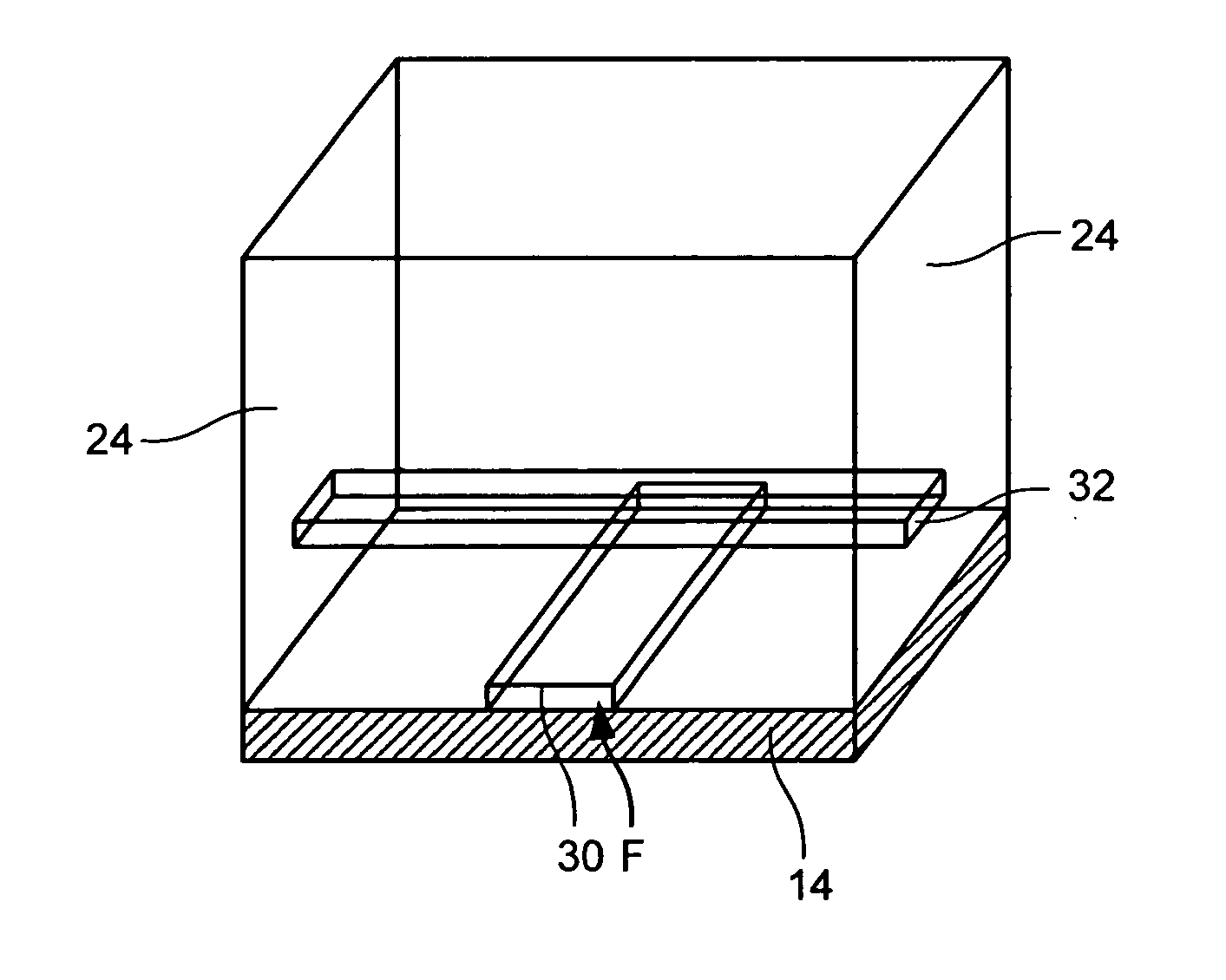

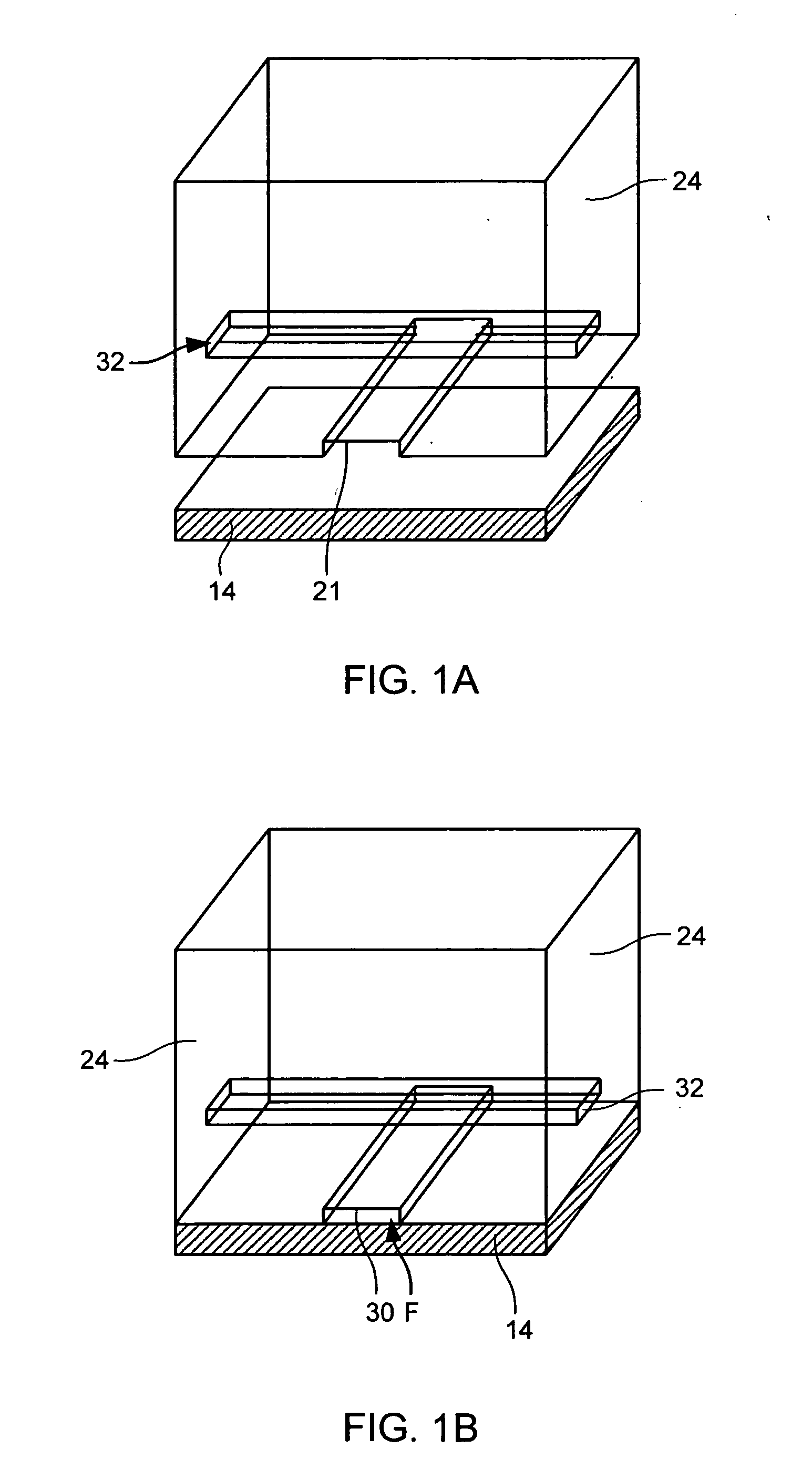

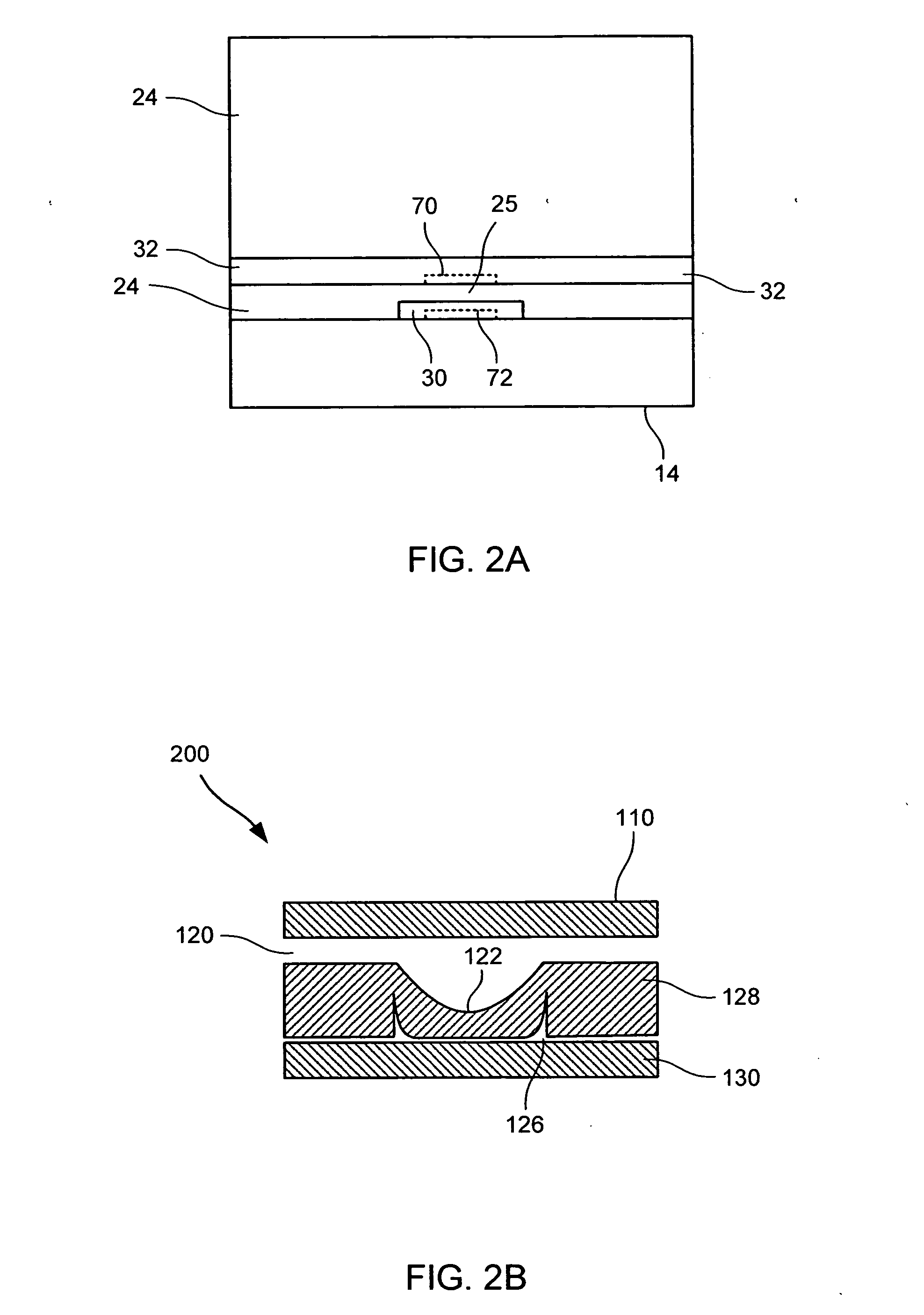

[0197] This example illustrates a method for producing a 4-layer microfluidic device having protein A (Staphylococcus aureus Fc binding protein) on its surface. The 4-layer device enables an assay to be performed at a precise location on a given solid substrate.

[0198] A fluid flow channel mold was prepared by spinning Shipley 5740 at 3600 rpm for 30 sec, soft baking for 60 s at 105° C. (measured thickness=7.8 μm), and hardbaking at 140° C. for 150 sec. (final mold thickness=10 μm). A control channel mold was prepared by spinning shipley 5740 at 850 rpm for 30 sec, followed by 5 min rest period prior to soft baking for 180 sec at 105° C. (final mold thickness=20 μm). A via mold was prepared by spinning AZ PLP 100-XT at 1240 rpm for 30 sec. followed by soft baking for 8 min at 95° C. (final mold thickness=35 μm).

[0199] Exemplary mold designs for each of the corresponding control layer (808), the fluid (i.e., flow channel) layer (804), and the via layer (812) are shown in FIGS. 8A-E....

example 2

[0237] This example illustrates a method for using a microfluidic device of the present invention for conducting a FLISA assay.

[0238] Using a microfluidic device of configuration shown in FIG. 11, various assays were conducted as follows:

Fluid Inputs

[0239] Fluid inputs A, B, C, and D are the reagent inlets. Through these inlets solutions of reagents, such as an antibody, can be added. When the proper valves are actuated, fluid flow from these inputs are directed into discrete areas of the chip. Fluid inputs E, F, G, and H are the sample inlets. Through these inlets solutions of reagents, such as analytes or antigens, can be added. When the proper valves are actuated, fluid flow from these inputs are directed into discrete areas of the chip. Fluid input I is a common wash inlet. This input connects to fluid lines adjacent to fluid inputs E-H. It may contain buffers or solutions common to all samples. It can also contain a buffers or solution to block the channel walls or block th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tm | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com