Blister package for adhesive compositions

a technology of compositions and adhesives, applied in the field of packaging, can solve the problems of deterioration of products, loss of desirable properties such as adhesion and ease of application, and achieve the effect of reducing moisture loss and prolonging the useful shelf life of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

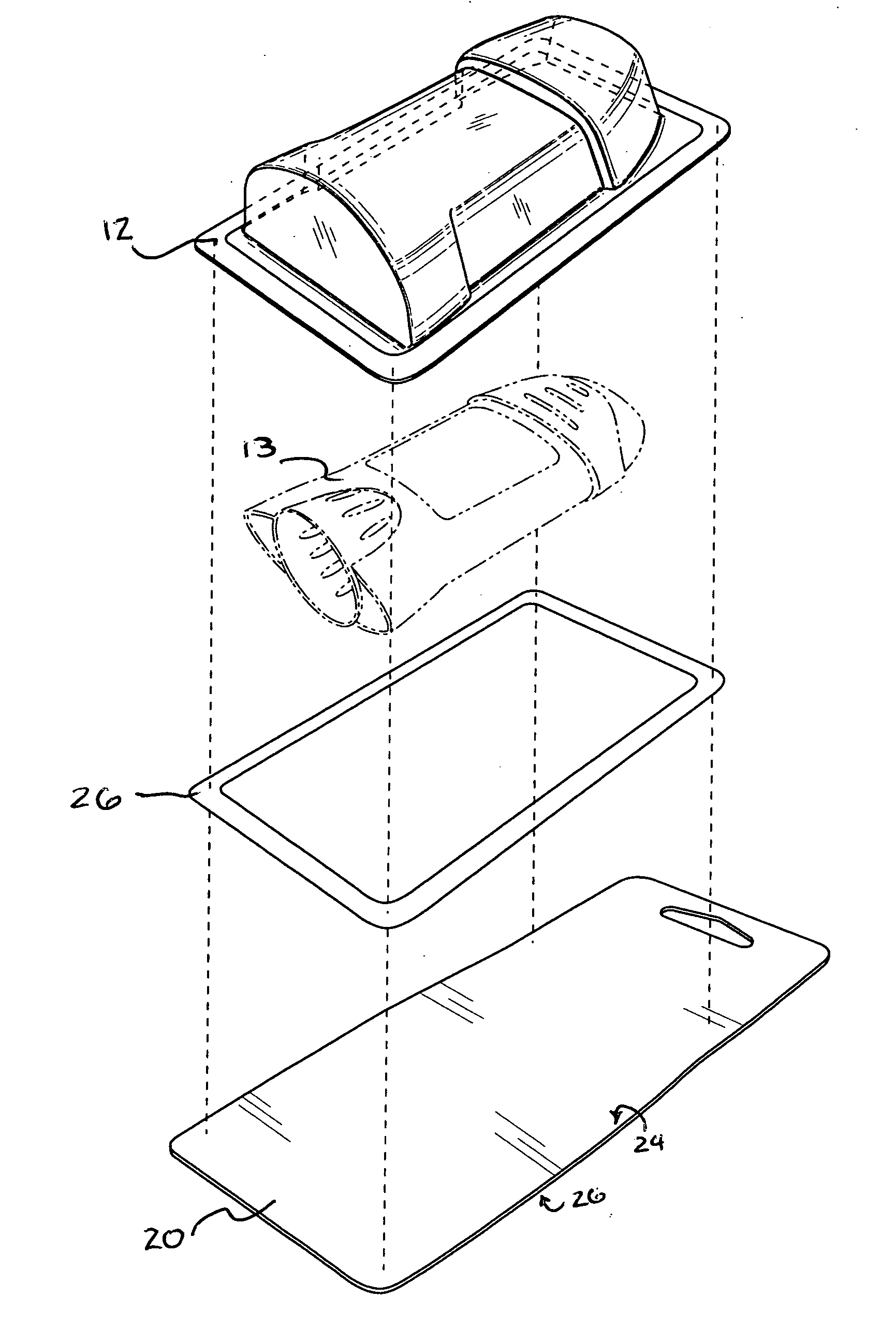

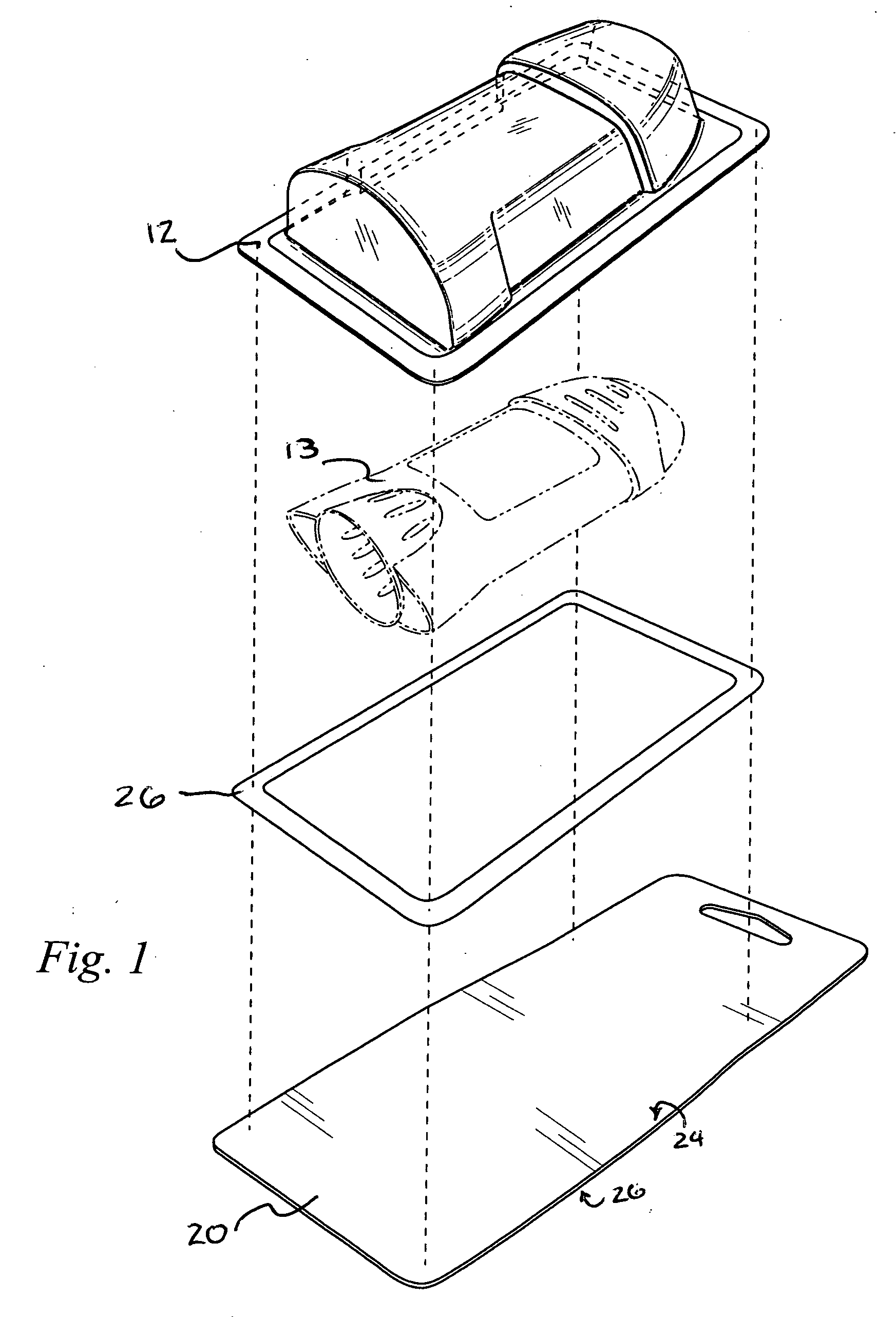

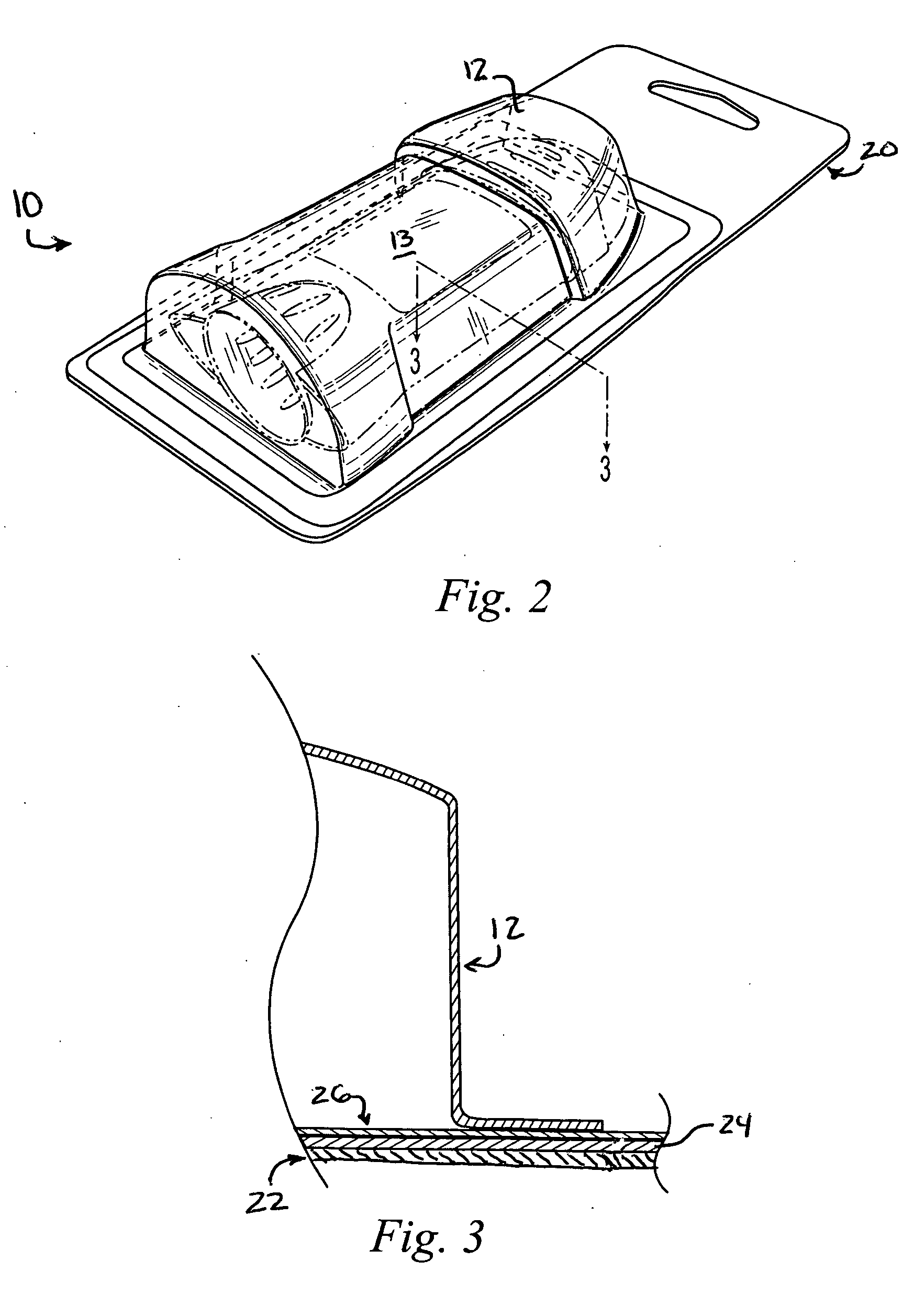

[0029] The inventors were able to evaluate a series of experimental blister packages, designated herein as the “S series” and the “L series”. The samples each included an Elmer's round glue stick in its primary HDPE package, but with the cap removed, packaged into a secondary blister package. Each blister package included a glue stick laid on a blister card, with a plastic blister overlaying the glue stick and sealed to the blister card using a polyethylene sealing ring as the sealing layer. Each blister and card assembly was than heat sealed at temperatures of between about 240 to 300 degrees Fahrenheit for sufficient dwell time to activate the sealing layer and create an airtight and durable seal between the blister card and the blister.

[0030] Each “S” series blister card included a paperboard backing having a 0.003 to 0.005 inch thick foil layer of aluminum foil on the exposed (top surface for contacting the product and plastic blister.

[0031] By contrast, each “L” series packag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com