Belt for continuously variable transmission and manufacturing method of the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

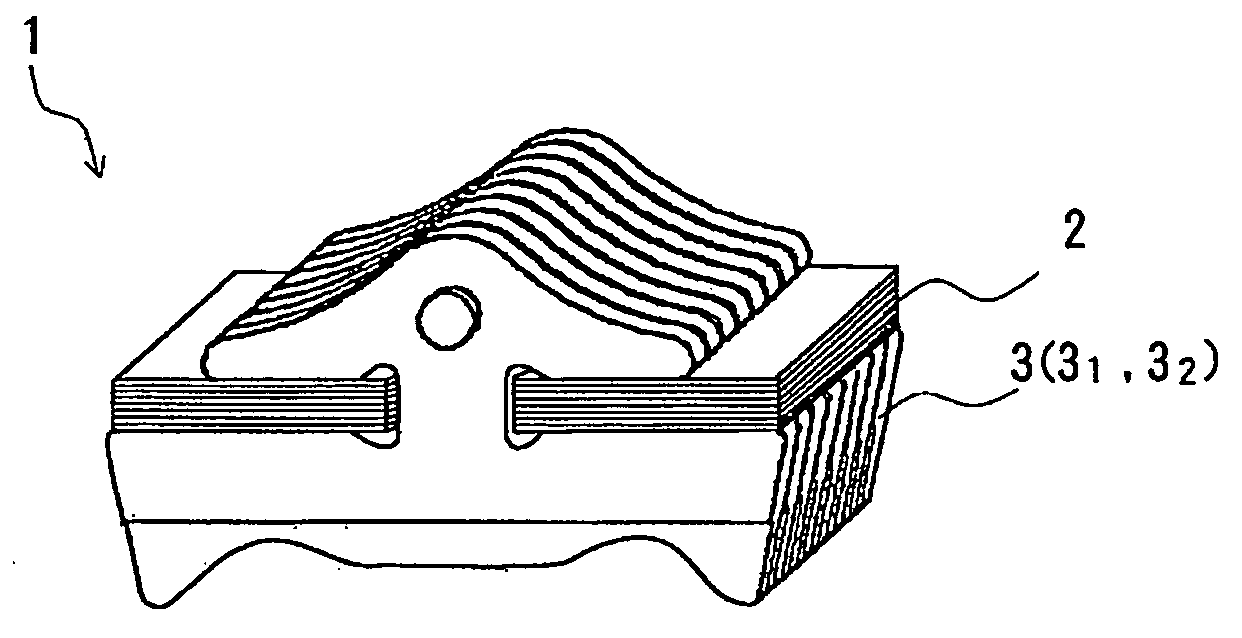

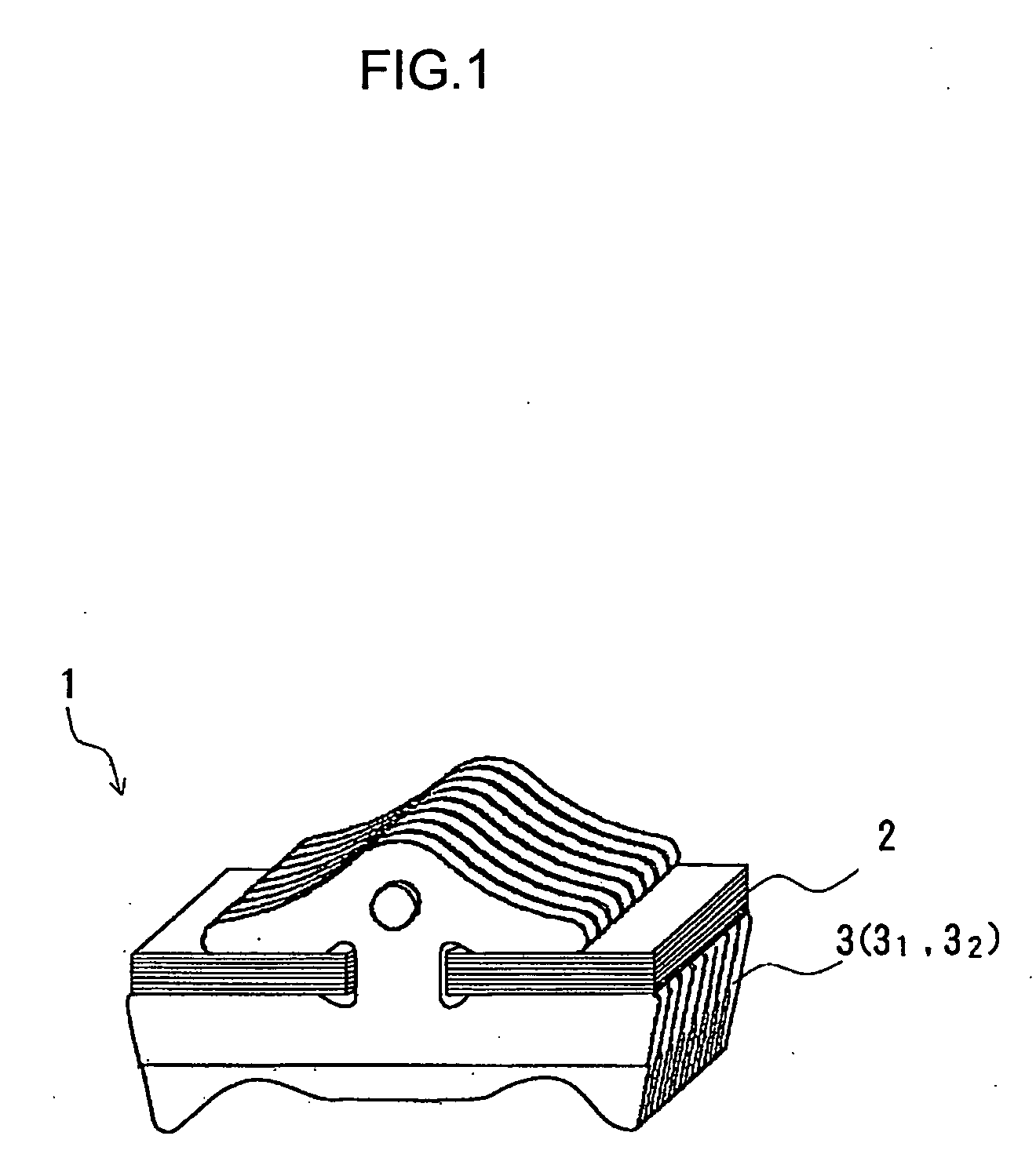

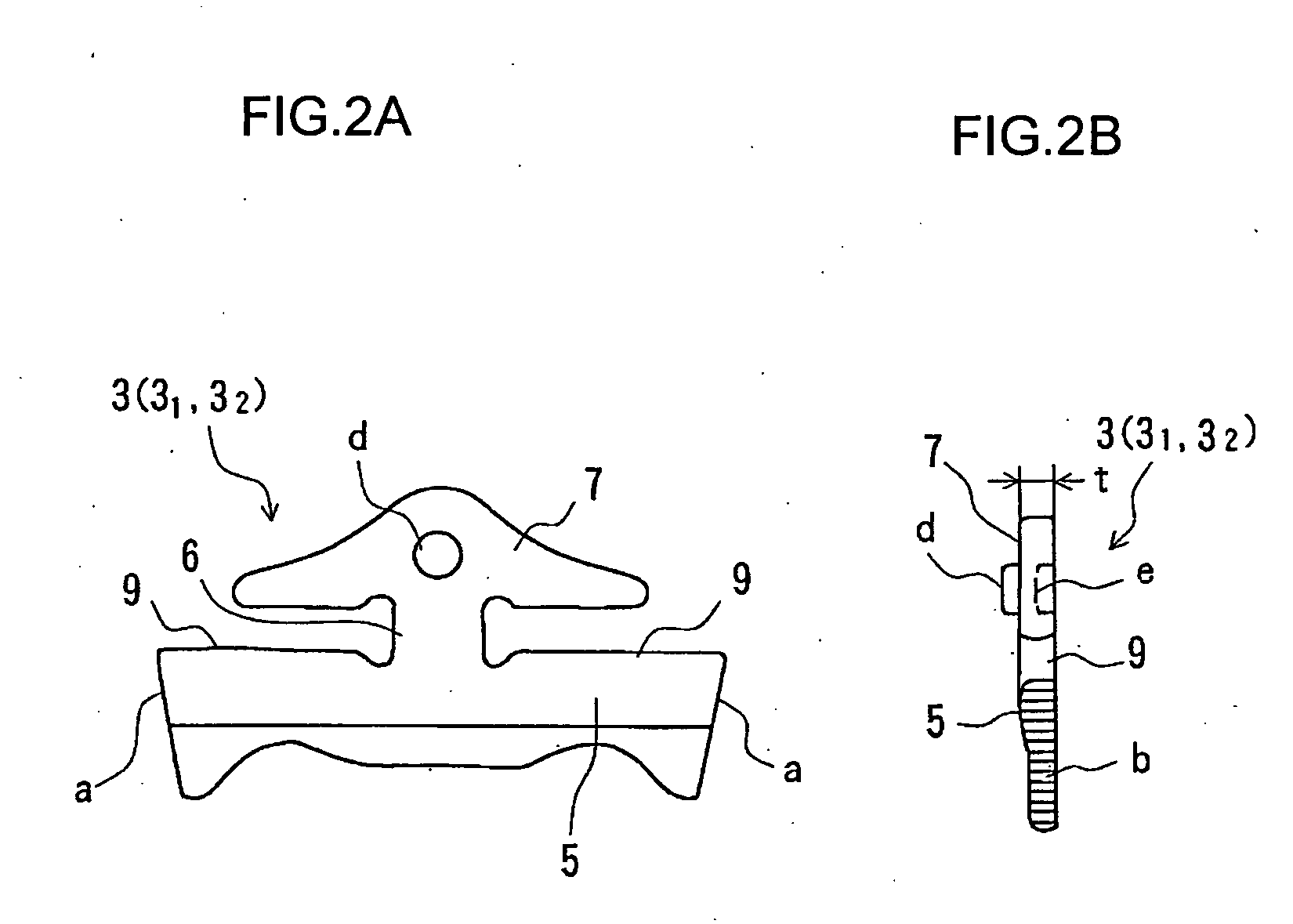

[0037] Exemplary modes for carrying out the invention will be explained below with reference to the accompanying drawings. FIG. 1 is a perspective view showing a part of a CVT belt and FIGS. 2A and 2B show a V block (element). The belt 1 is composed of a ring 2 in which a plurality of endless metal sheets are laminated and a large number of V blocks (elements) 3 are successively and endlessly attached to the ring 2. As shown in FIG. 2, in detail, the V block 3 is a plate made of steel, for example, and has a certain thickness. The V block has a body 5 with V-shaped right and left flanks a that abut against pulleys, and a head 7 linked with the body 5 via a pillar 6. A part between the body 5 and the head 7 on the right and left sides of the pillar 6 is a saddle 9 for receiving the ring 2. Channels b for flowing lubricant oil are formed on the right and left flanks a, and the head 7 is provided with a dimple d on one face thereof and with a hole e on the other face to maintain the at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

| Level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com