Cathode systems for electrolytically obtaining aluminum

a cathode and aluminum technology, applied in the field of cathode systems for the electrolytic production of aluminum, can solve the problems of increasing the cost of cathode production, affecting the production efficiency of cathode, and the installation of contact pins and the machining of the recesses on the adjoining parts, so as to achieve the effect of not increasing the variety of production measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0060] Graphite cathodes of conventional construction having a length of 3 300 mm were provided with conventional steel supports as collectors and connected electrically by introduction of ramming pastes having differing resistances. Here, the ratio of the specific resistance of the tamping composition in the region near the edge to that in the central region is 5:1. An electrolysis cell equipped in this way with 20 cathode blocks was operated at a current of 220 kA and 4.4 V for 1 000 days. For comparison, cells were operated using the same cathode system but a uniform tamping composition.

[0061] After the period of operation indicated, the cells were emptied and dismantled, and the cathodes were examined for wear. While in the case of the cathodes having a uniform construction the removal of material in the two edge zones was about 7.5 cm and that in the middle of the cathode was only 2.5 cm, in the case of the configuration according to the invention the removal of material in th...

example 2

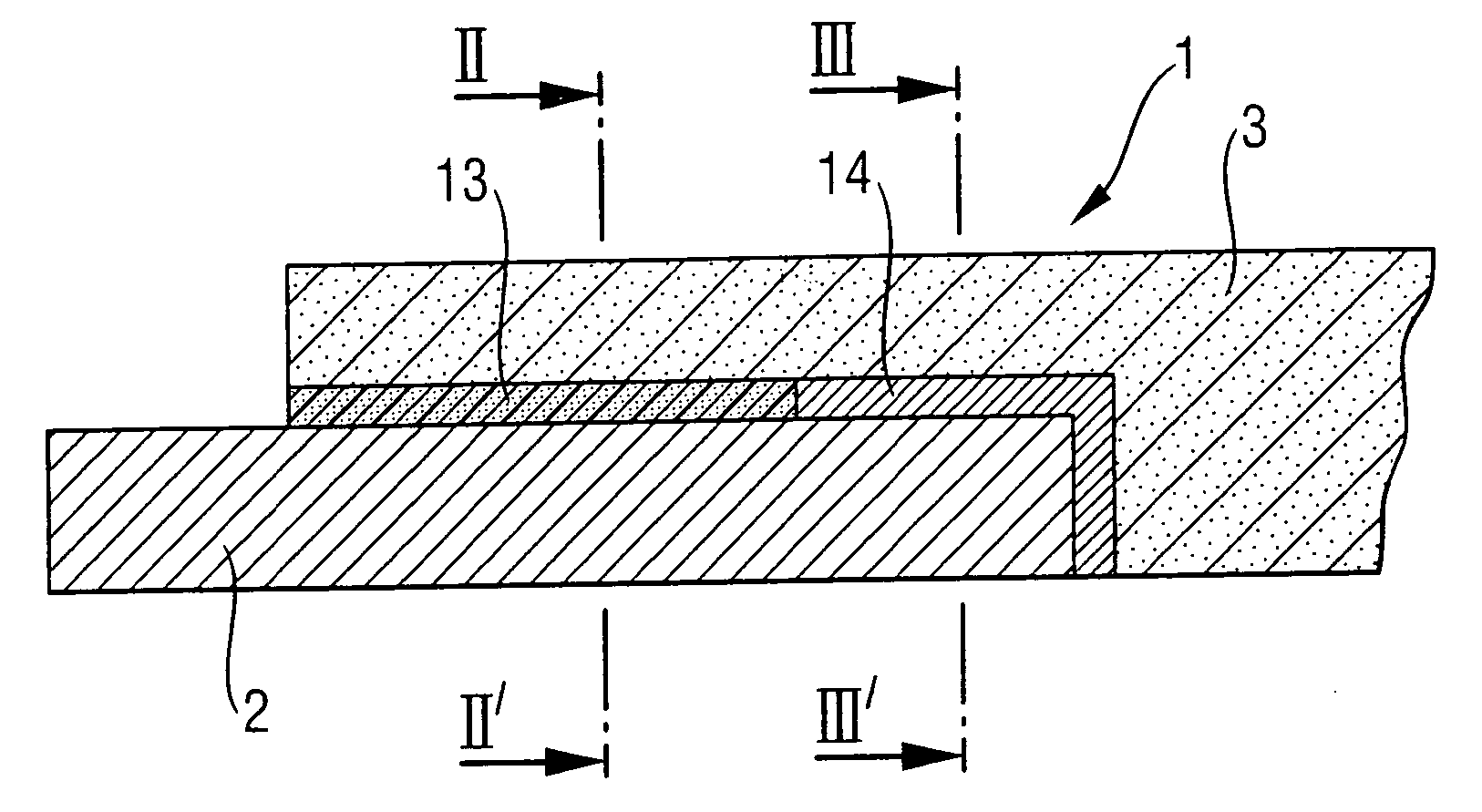

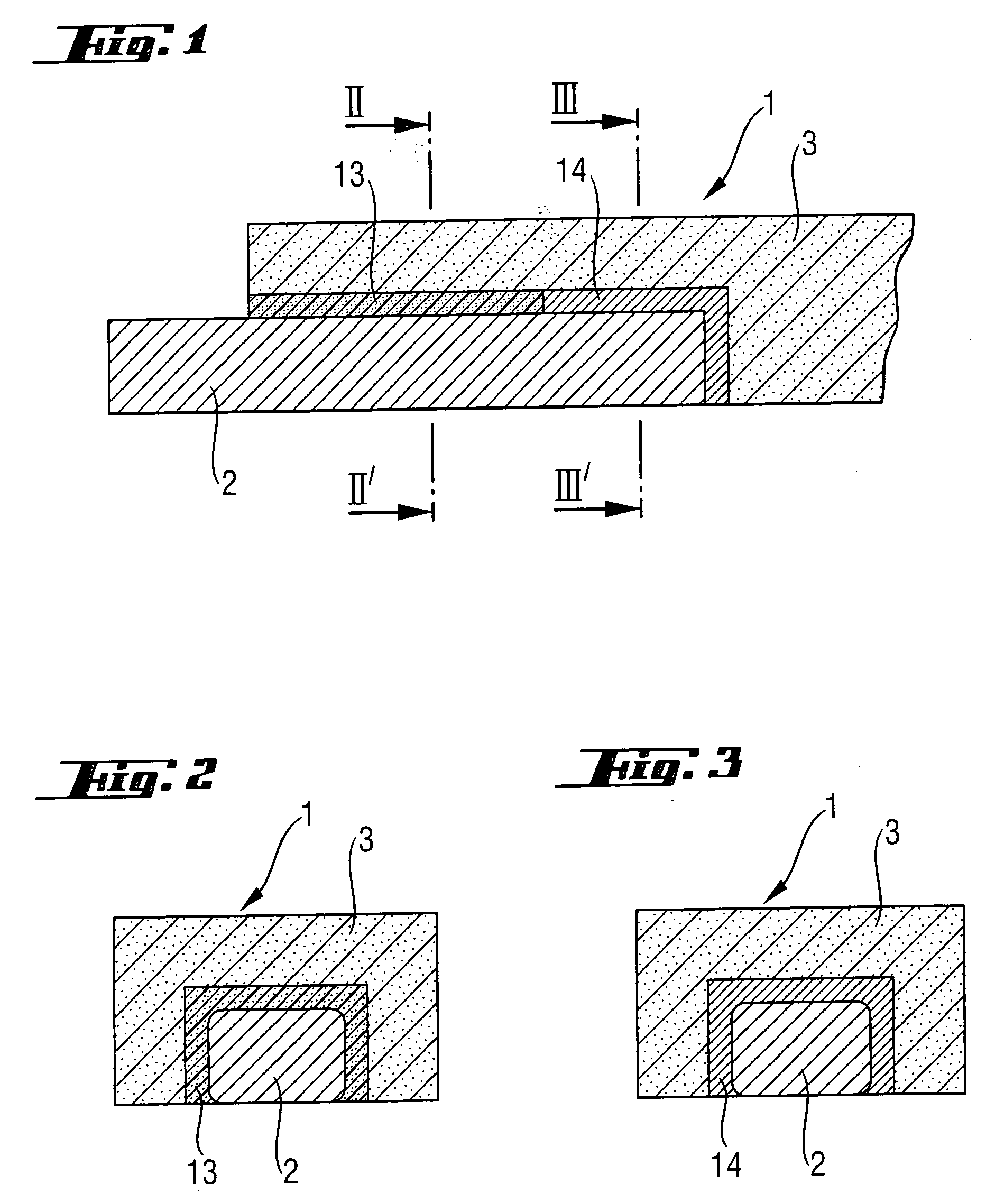

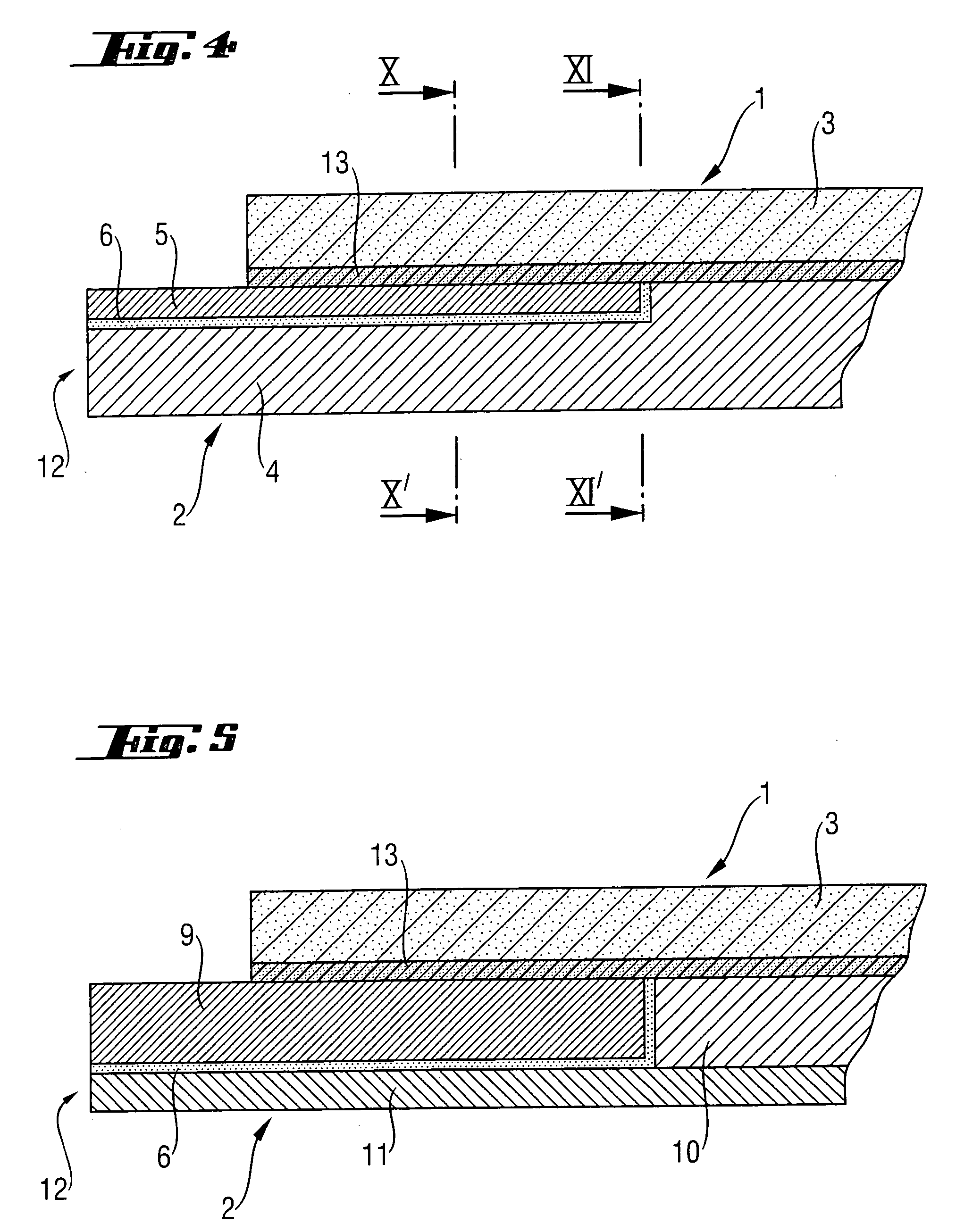

[0062] Graphite cathodes of conventional construction having a length of 3 300 mm were provided with conventional steel supports as collectors and connected electrically in a conventional way by introduction of a tamping composition. An electrolysis cell having 20 cathode blocks was operated at a current of 220 kA and 4.4 V for 1 000 days (comparison). According to the invention, the same cathodes were joined to steel supports like those shown as 2 in FIG. 4 whose ends had been milled down to ⅚ of their original thickness to a distance of about 700 mm from the end of the cathode. The transition to the unmachined middle zone had an angle of about 160° as shown in FIG. 7. The milled area was covered with a mica sheet 6 having a thickness of about 0.3 mm, and a steel plate 5 having appropriate dimensions was fastened on top of this at each end of the support with the aid of sleeves of the type shown in FIG. 9 which were insulated with mica sheets.

[0063] The steel supports or collector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com