Heat pipe with screen mesh wick structure

a technology of wick structure and heat pipe, which is applied in the field of heat pipe, can solve the problems of reducing the speed of condensed working fluid, limiting the heat transfer performance of heat pipe, and not always the best way to choose a screen mesh having small pores, etc., and achieves a large capillary pressure and reduces the flow resistance of condensed fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

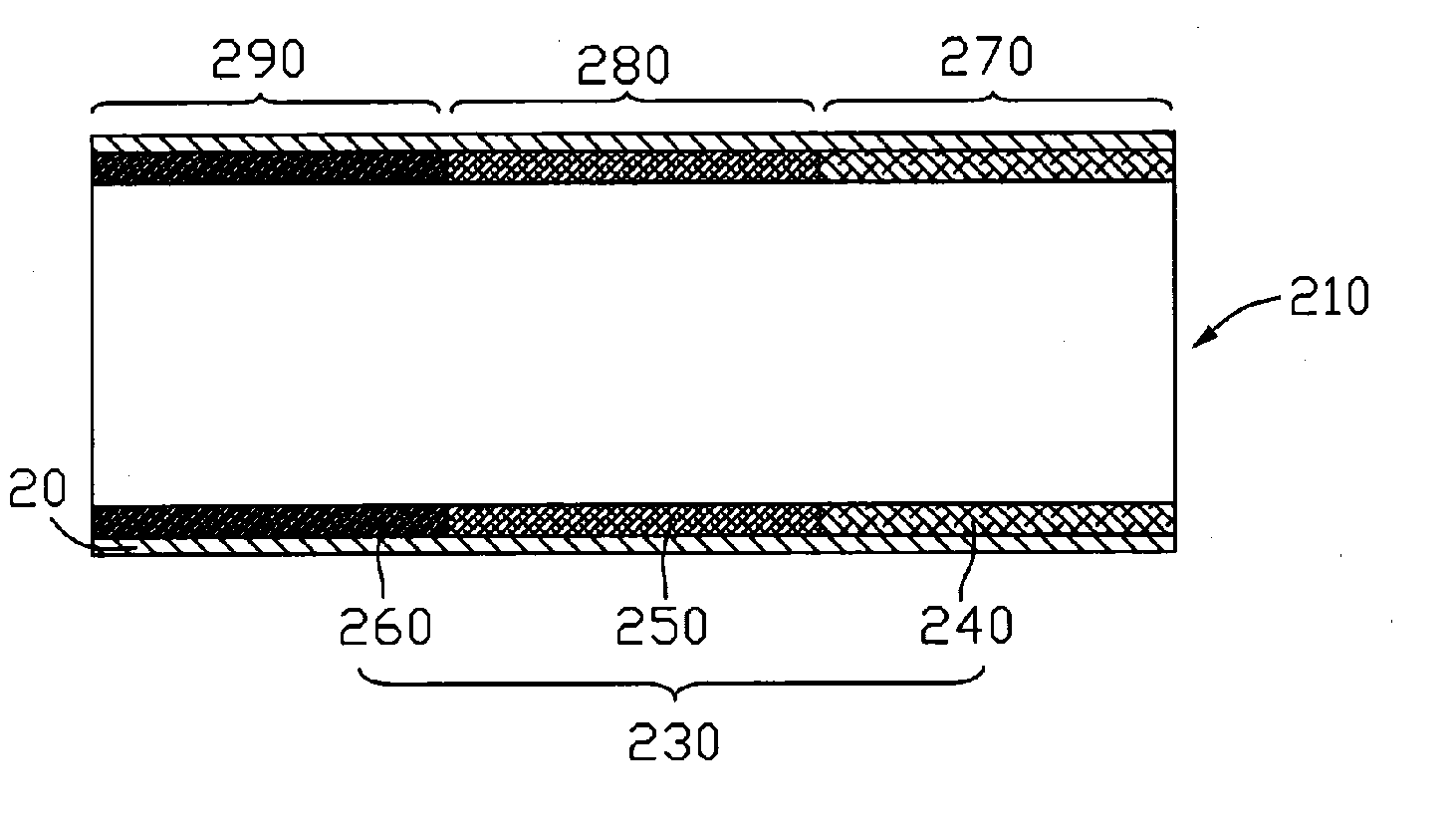

[0020]FIG. 1 illustrates a heat pipe 10 in accordance with the present invention. The heat pipe 10 comprises a pipe body 20 and a screen mesh 30 disposed on an inner wall 22 of the pipe body 20. The heat pipe 10 comprises an evaporating section 70 and a condensing section 90 at respective opposite ends thereof, and an adiabatic section 80 located between the evaporating section 70 and the condensing section 90.

[0021] The pipe body 20 is typically made of high thermally conductive materials such as copper or copper alloys. The screen mesh 30 is saturated with a working fluid (not shown), which acts as a heat carrier for carry thermal energy from the evaporating section 70 toward the condensing section 90 when undergoing phase change from a fluid state to a vaporous state. The working fluid may be water, alcohol or other material having a low boiling point and the heat pipe 10 is vacuumed; thus, the working fluid can easily evaporate to vapor during operation.

[0022] Along a longitudi...

fourth embodiment

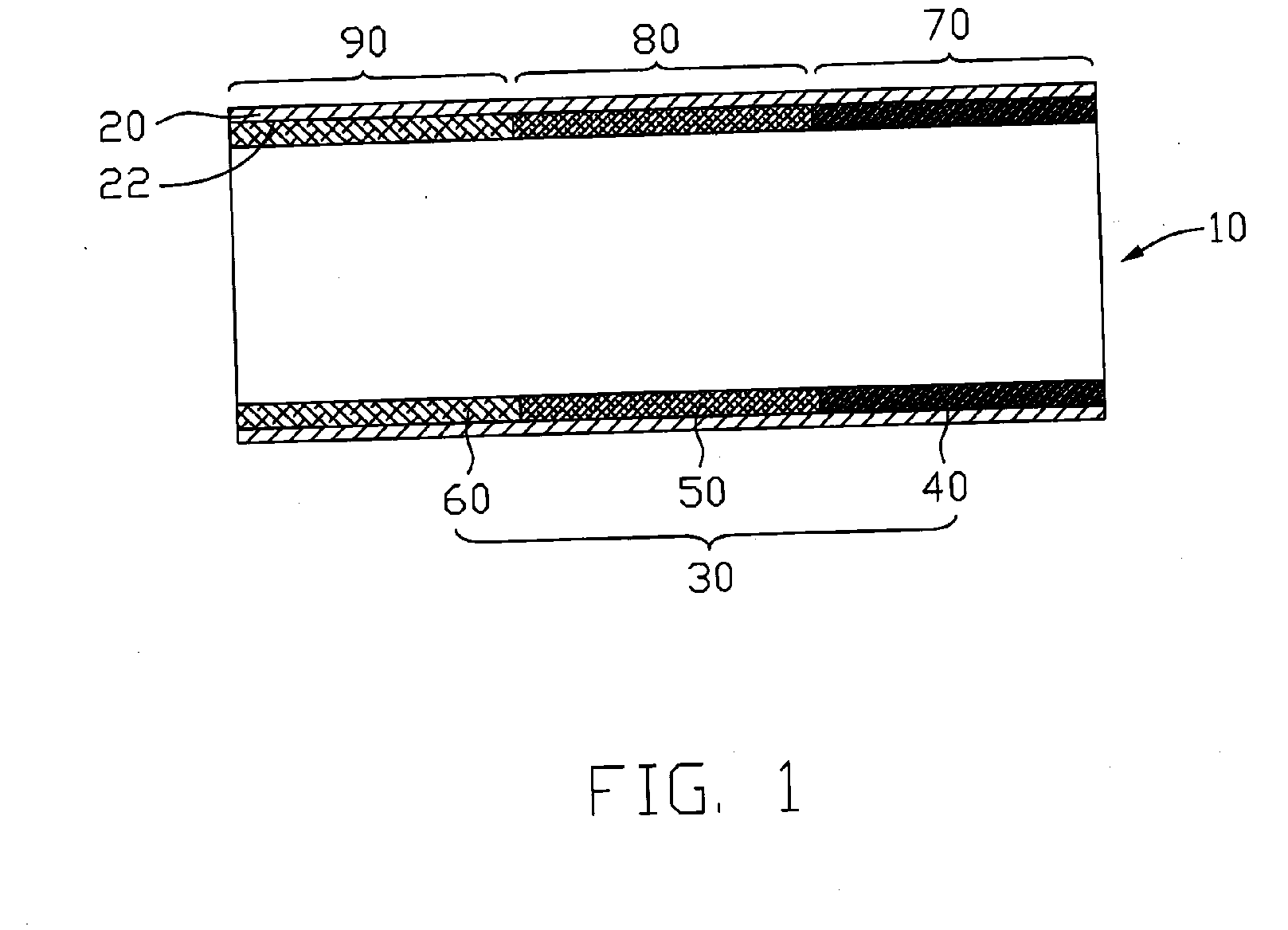

[0025]FIG. 4 illustrates a heat pipe 410 according to the present invention. The heat pipe 410 includes a pipe body 20 and a screen mesh 430 arranged in the pipe body 20. The screen mesh 430 is in the form of a multi-layer structure, which comprises an outer layer 440, an intermediate layer 450 and an inner layer 460. These layers 440, 450, 460 are stacked together along a radial direction of the pipe body 20 with the outer layer 440 abutting the inner wall 22 of the pipe body 20. Each layer of the screen mesh 430 has an average pore size different from that of the other layers, and these layers 440, 450, 460 are stacked together in such a manner that the average pore sizes thereof gradually increase along the radial direction from the inner wall 22 of the pipe body 20 towards a central axis X-X of the pipe body 20.

[0026] According to the above-mentioned general rule, the capillary pressure of a wick and its flow resistance to the condensed fluid increase due to a decrease in pore s...

seventh embodiment

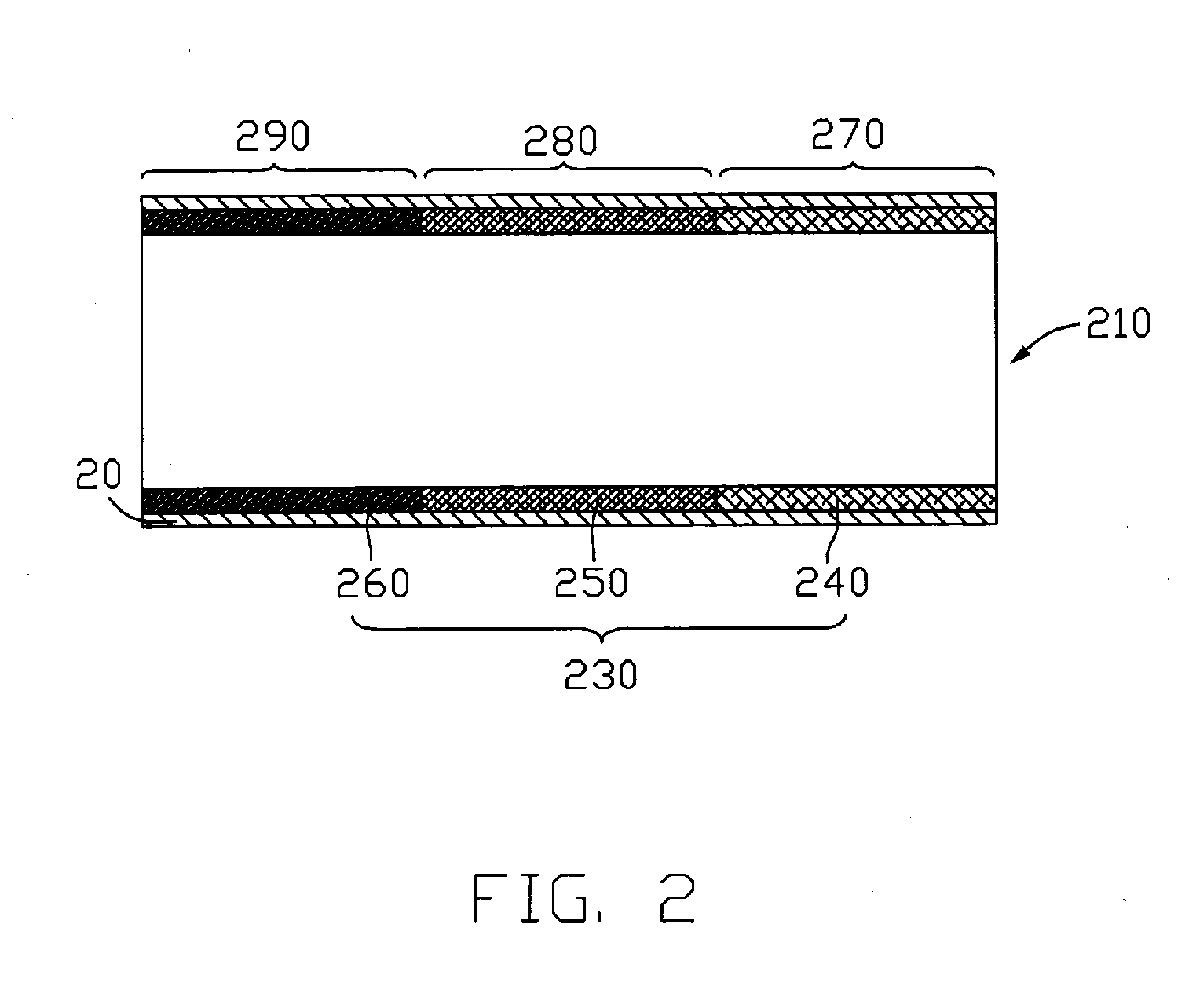

[0029]FIG. 7 illustrates a heat pipe 710 according to the present invention. The heat pipe 710 comprises a screen mesh 730 having the outer, intermediate and inner layer 740, 750, 760 arranged along a radial direction of the pipe body 20. Each layer comprises three sections arranged along the longitudinal of the heat pipe 710. The outer layer 740 is divided into a first section 67, a second section 68 and a third section 69 corresponding to the evaporating, adiabatic and condensing section 770, 780, 790 of the heat pipe 710, respectively. Similar to the outer layer 740, the inner layer 760 comprises a first, second and third section 47, 48, 49, and the intermediate layer 750 comprises a first, second and third section 57, 58, 59. Each section of a specific layer has an average pore size different from that of the other sections of the specific layer. Thus the screen mesh 730 is in the form of multi-layer structure either along the longitudinal direction or along the radial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com