Ventilating shoe pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

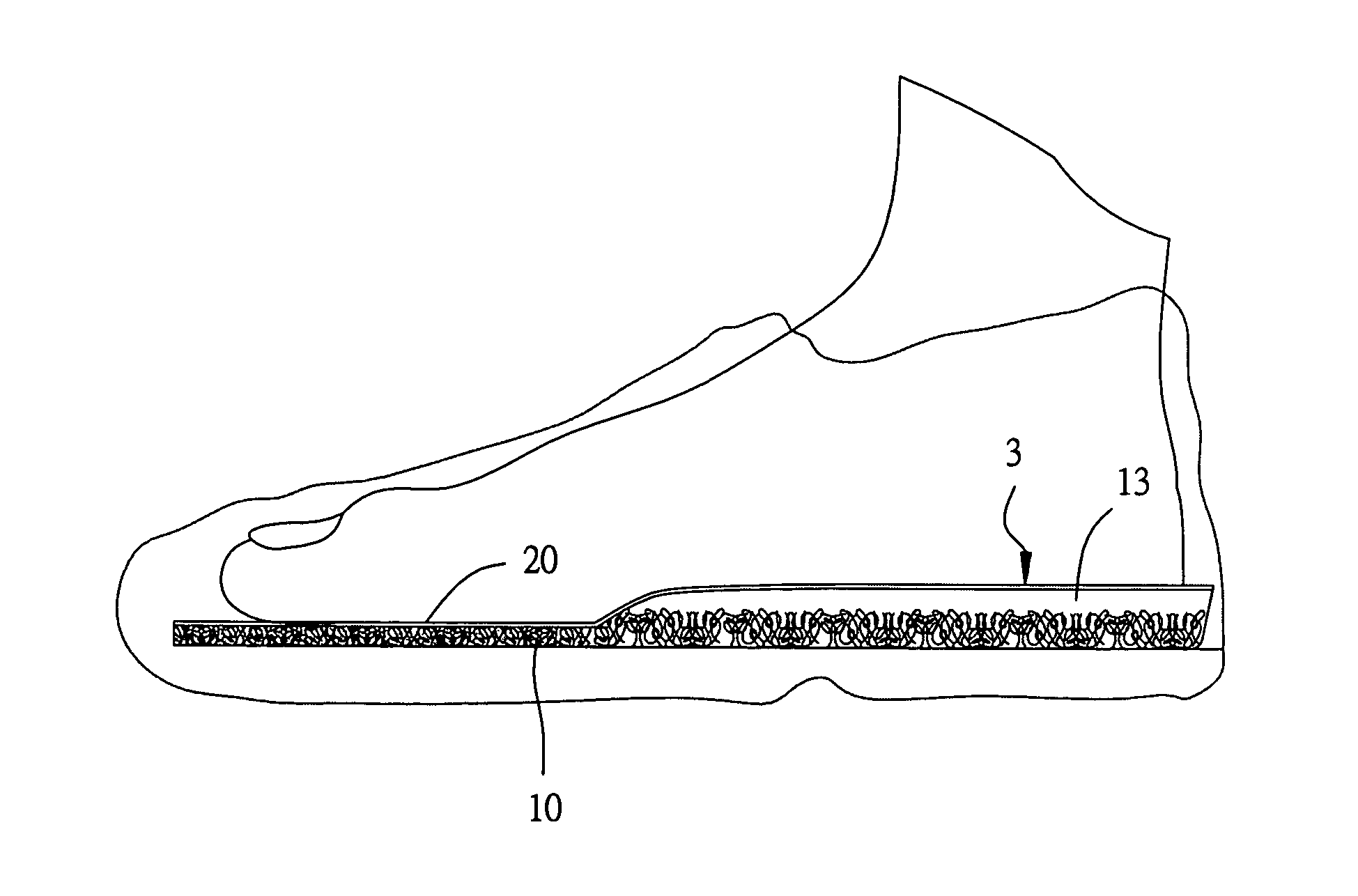

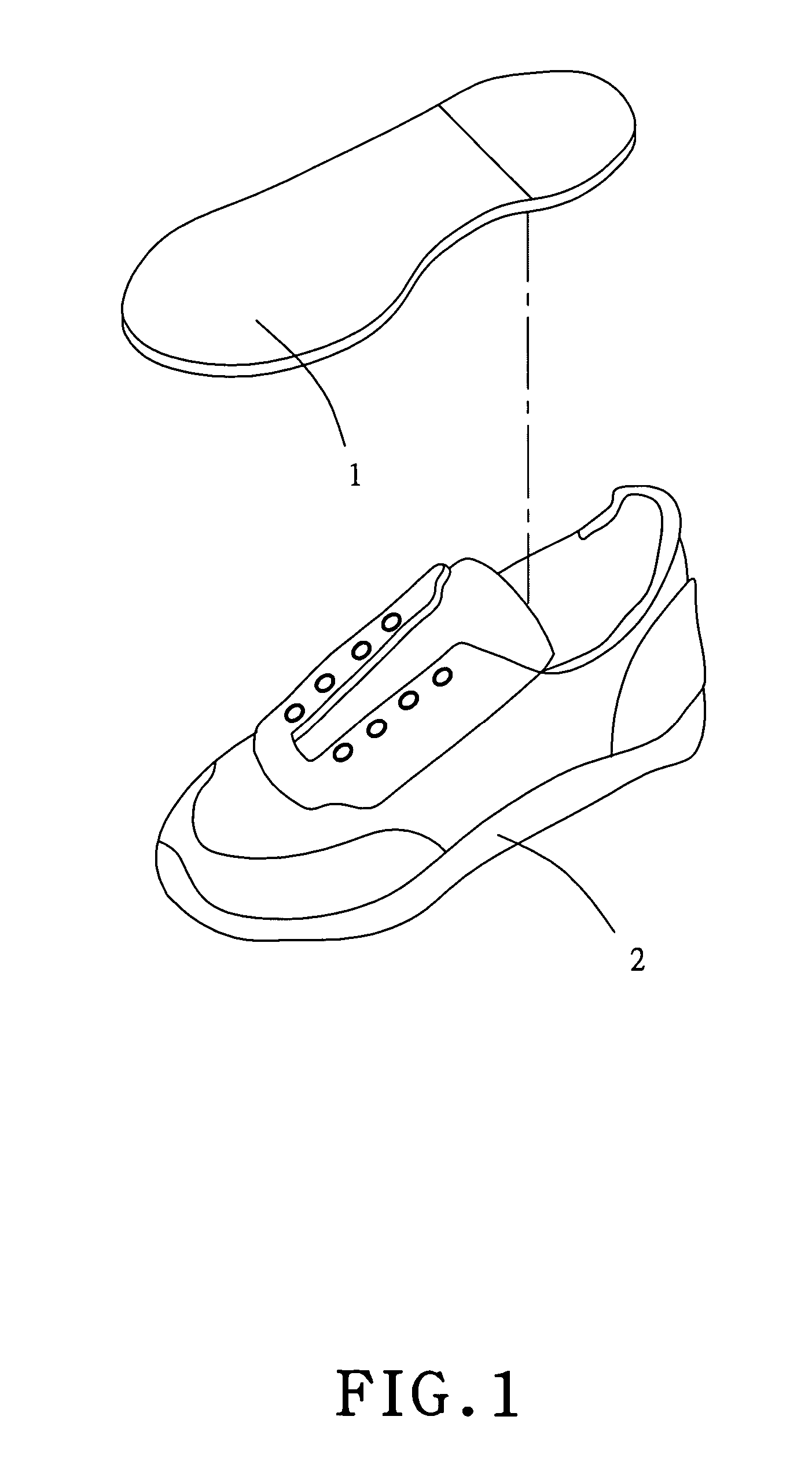

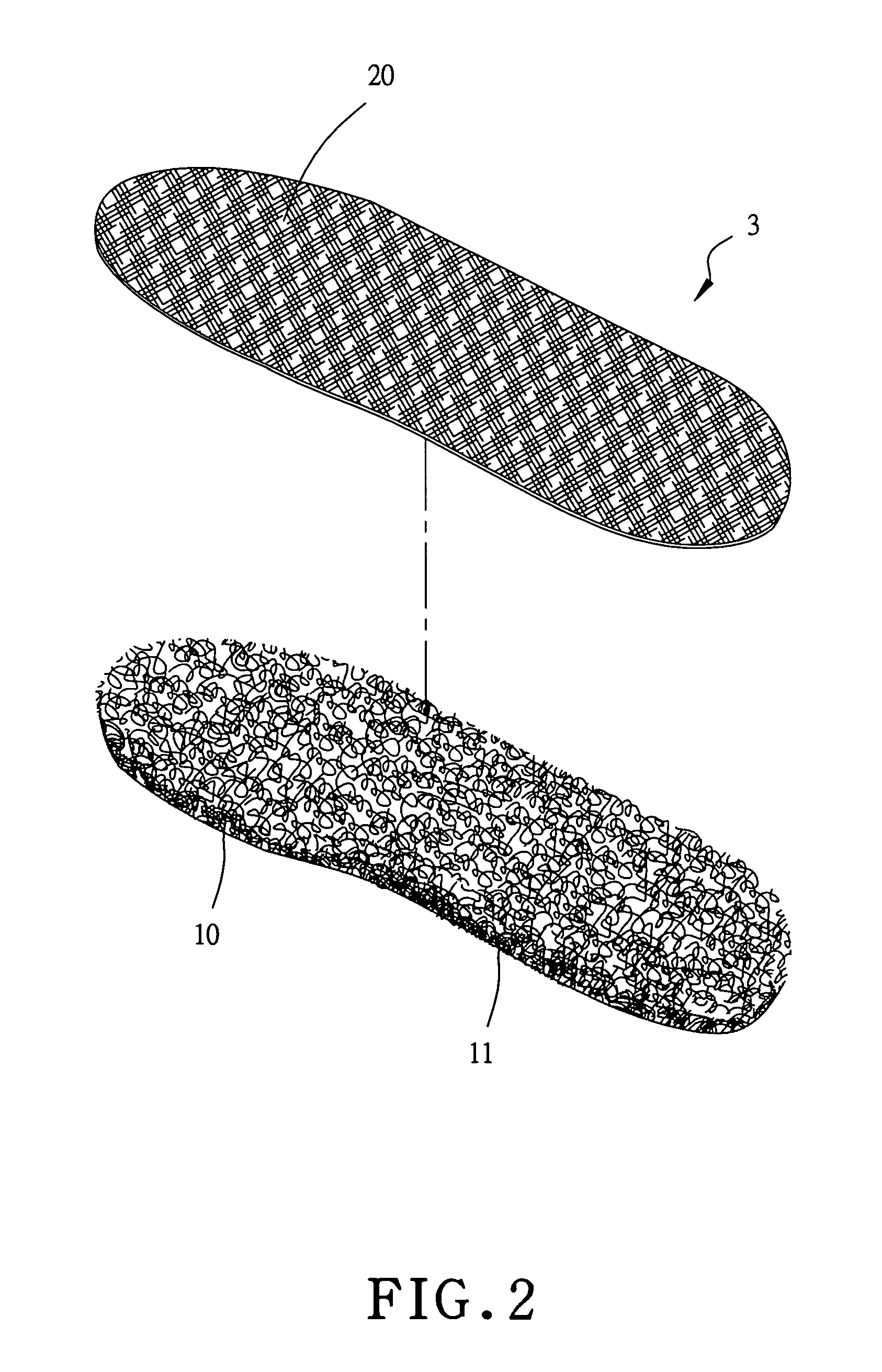

[0014] A first preferred embodiment of a ventilating shoe pad 3 in the present invention, as shown in FIGS. 2 and 3, includes a pad body 10 and a cushion 20 combined together.

[0015] The pad body 10 is made of plenty of elastic fiber 11 made from plastic materials, such as PVC, PP or PE. The elastic silk 11 is loosely and separately interwound together, with numerous gaps 12 formed among the interwound silk 11. Further, the pad body 10 is formed by thermal compression with a protective edge 13 slightly extending upward obliquely at the peripheral edge corresponding to the recessed portion and the heel of a user's foot.

[0016] The cushion 20 is made of knitted fabric, having its shape and size approximately matching with those of the pad body 10. The cushion 20 is glued on the pad body 10 with adhesive for a user's foot to step thereon.

[0017] In a process of making ventilating shoe pads of the invention, an integral-sheeted cushion 20 and an integral-sheeted pad body 10 can be glued...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com