Lubricating pack specifically designed for paper shredders

a technology of lubricating pack and paper shredder, which is applied in the direction of packaging, other accessories, metal working apparatus, etc., can solve the problems of shortening reducing cutting efficiency, and increasing the manufacturing cost of paper shredders, so as to prolong the life of paper shredders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

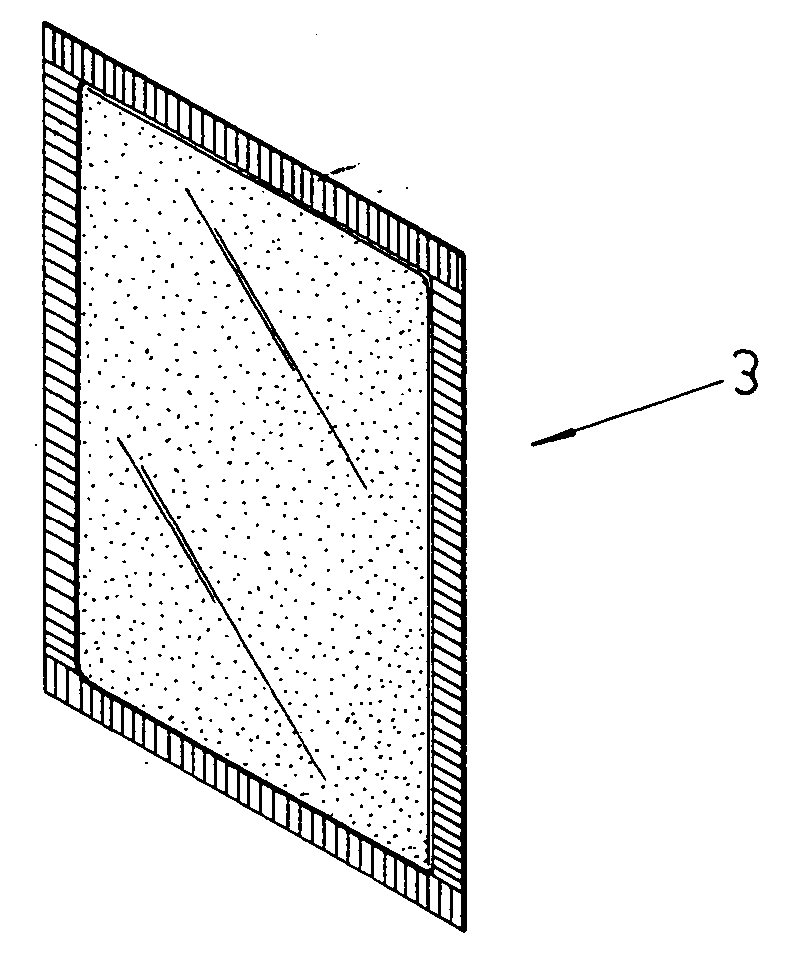

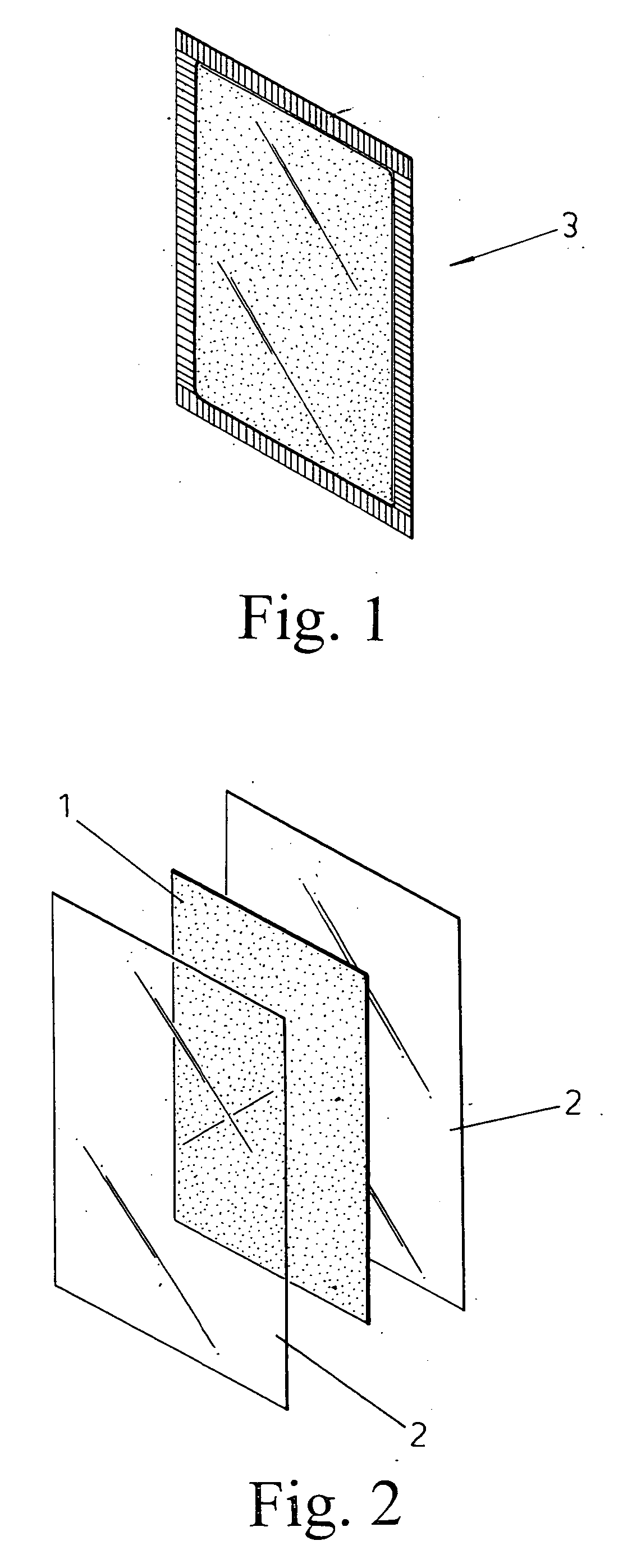

[0017]FIGS. 1 and 2 illustrate a perspective view and an exploded, perspective view of a lubricating pack specifically designed for paper shredders according to this invention, respectively. A piece of oiled paper 1 saturated with lubricant is placed between an upper and a lower plastic sheets or films 2. The upper and lower plastic sheets / films 2 sandwich the oiled paper therebetween and then fused around their peripheries by adopting conventional high-frequency fusion or equivalent measures to form a lubricating pack 3 having a laminating construction.

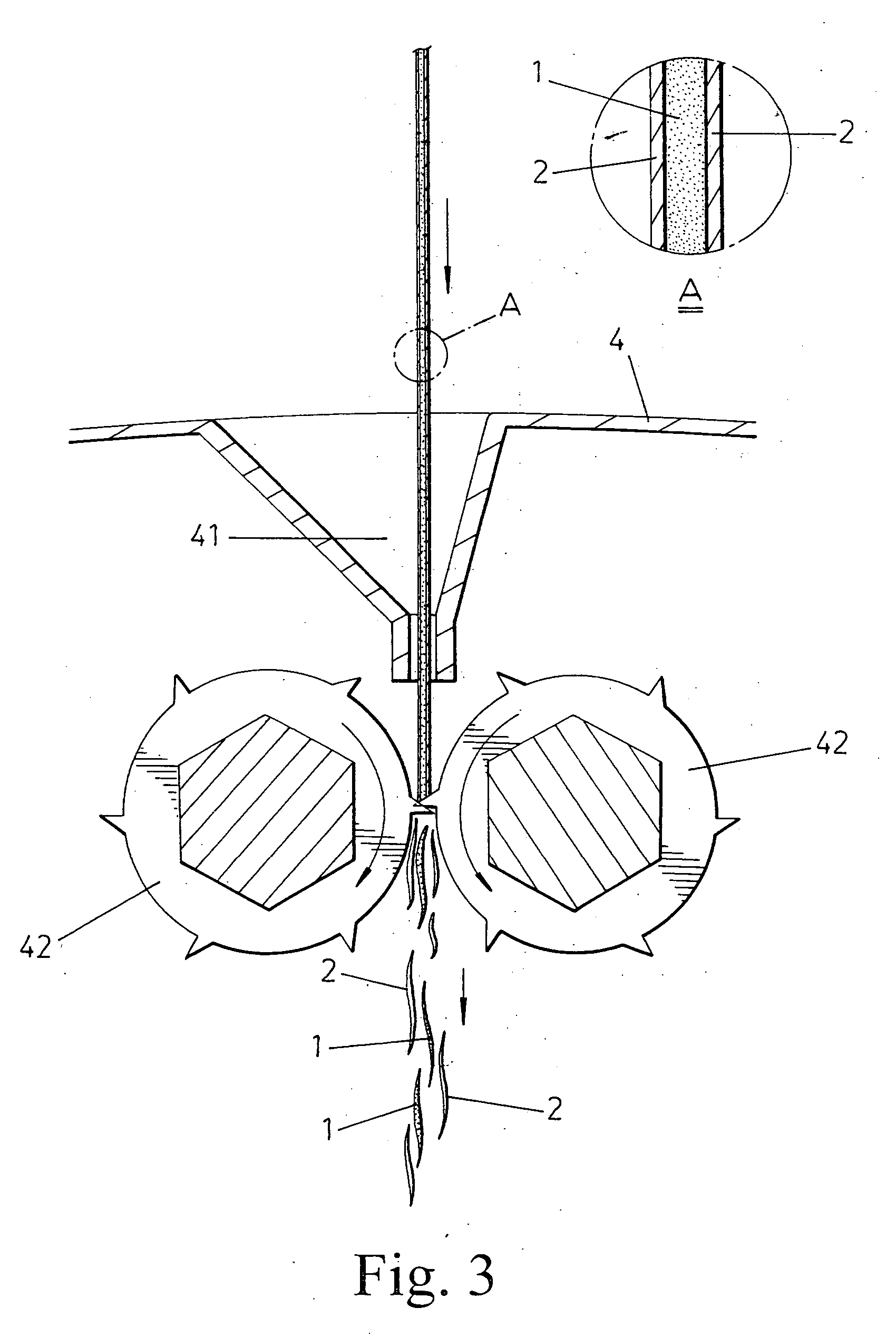

[0018] As shown in FIG. 3, the lubricating pack 3 specifically designed for paper shredders according to this invention is directly fed into a paper inlet 41 of a paper shredder 4 under paper-feeding mode to shred the lubricating pack 3. Accordingly, the cutting blades 42 of the paper shredder 4 would contact the lubricant contained in the oiled paper 1 directly during the process of shredding the lubricating pack 3, so as to provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com