Method for controlling a hydraulic system of a mobile working machine

a mobile working machine and hydraulic system technology, applied in the direction of fluid couplings, positive displacement liquid engines, couplings, etc., can solve the problems of complex load distribution and change, control system cannot allow for one load-dependent reduction in the speed of the internal combustion engine, and cannot be controlled satisfactorily by the method described

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

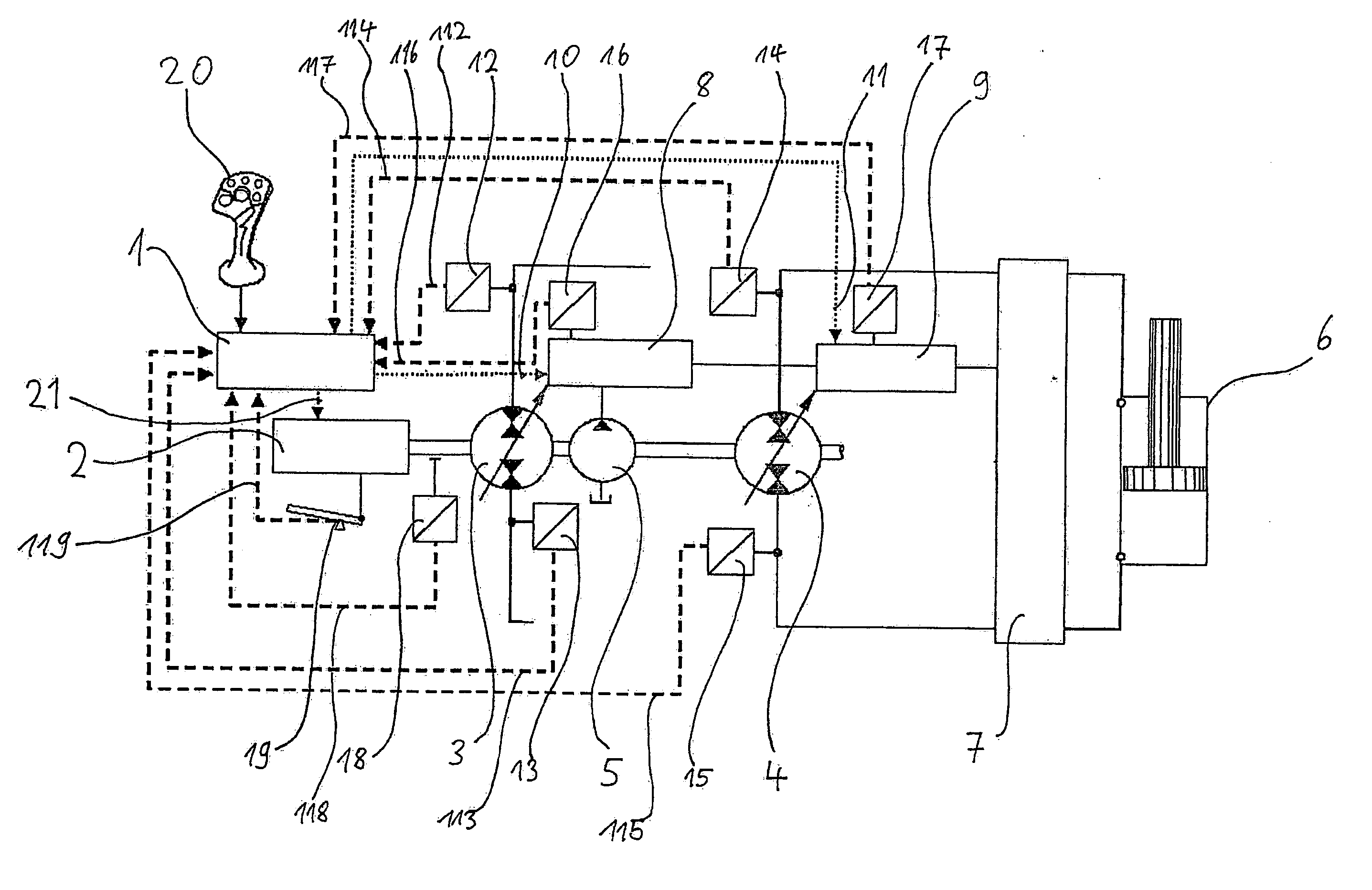

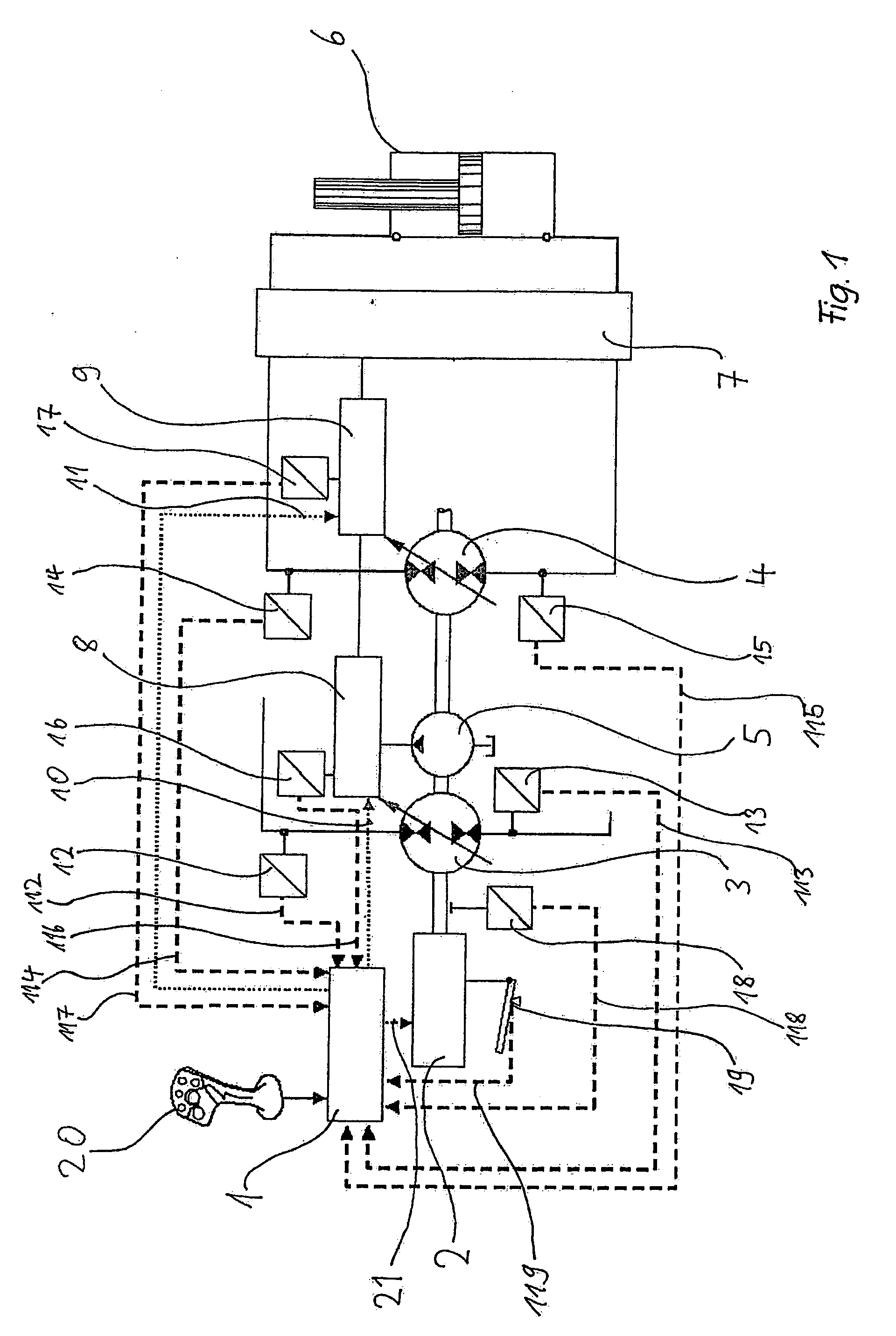

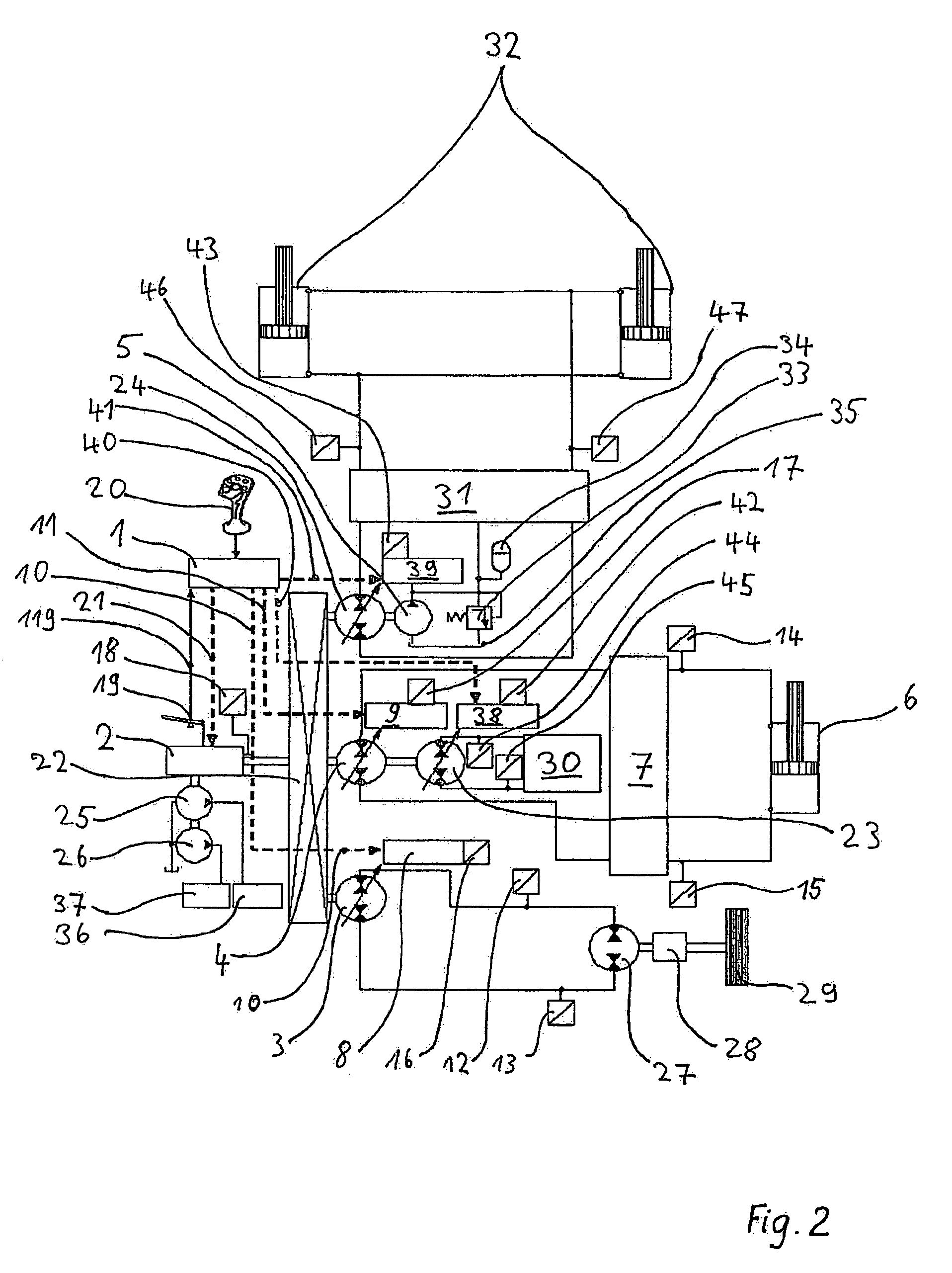

[0029] Referring to FIG. 1, the electronic control system designated 1 is used to control a hydraulic system of a self-propelled working machine. This hydraulic system has an internal combustion engine 2, which drives two pumps with adjustable volumetric displacement 3 and 4 and a fixed-displacement pump 5 in an initial configuration. The adjustable pump 3 is used to drive a hydraulic transmission system with a rotary engine (not shown in more detail here). The adjustable pump 4 drives a displacement-controlled machine hydraulic system with a differential cylinder 6 as a linear motor. A valve manifold 7 (not shown in more detail) ensures the necessary compensation for the difference in volumetric flow and the other necessary hydraulic functions such as overload protection, etc. The fixed-displacement pump 5 and an accumulator charging circuit (not shown in more detail) form the low-pressure system of the machine and supply low pressure to the hydraulically-operated volumetric displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com