Silicon nano wire having a silicon-nitride shell and method of manufacturing the same

a silicon nano wire and nano-nitride technology, applied in the direction of polycrystalline material growth, crystal growth process, transportation and packaging, etc., can solve the problems of low luminescence efficiency of less than 1%, limited use of photo luminescence method, and difficult to achieve, and achieve good light emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will now be described more fully with reference to the accompanying drawings in which exemplary embodiments of the invention are shown. Like reference numerals refer to like elements throughout the drawings.

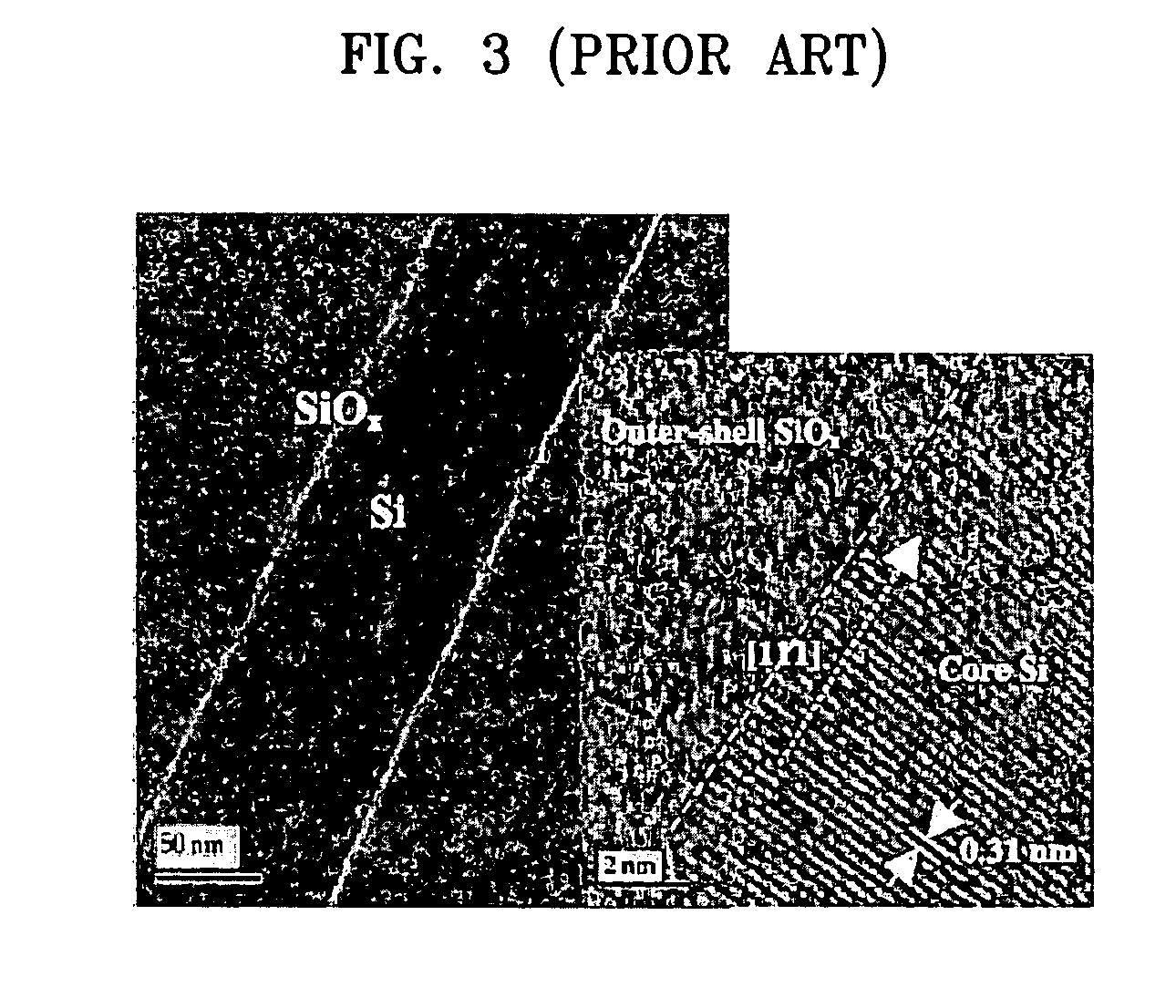

[0030]FIG. 3 is a SEM image of a conventional silicon nano wire having a silicon oxide shell. The silicon nano wire has a silicon core portion composed of crystalline silicon and a silicon oxide shell portion. The silicon oxide shell portion is generally formed by native oxidation and can also be formed by thermal oxidation. While the silicon oxide is formed at the surface of the silicon nano wire, as the silicon oxide shell portion grows, the diameter of the silicon core portion decreases, since the silicon oxide grows not only radially, but also grows toward the center of the silicon nano wire. However, the silicon oxide grows so rapidly that the diameter of the silicon nano wire using the silicon oxide shell portion cannot be controlled.

[0031] Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com