Post trim system

a technology for trim and posts, applied in the direction of columns, pillars, struts, etc., can solve the problems of difficult plastic sleeve production, etc., and achieve the effect of improving mechanical connection, increasing strength, and relatively low overall thickness of the post sleev

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

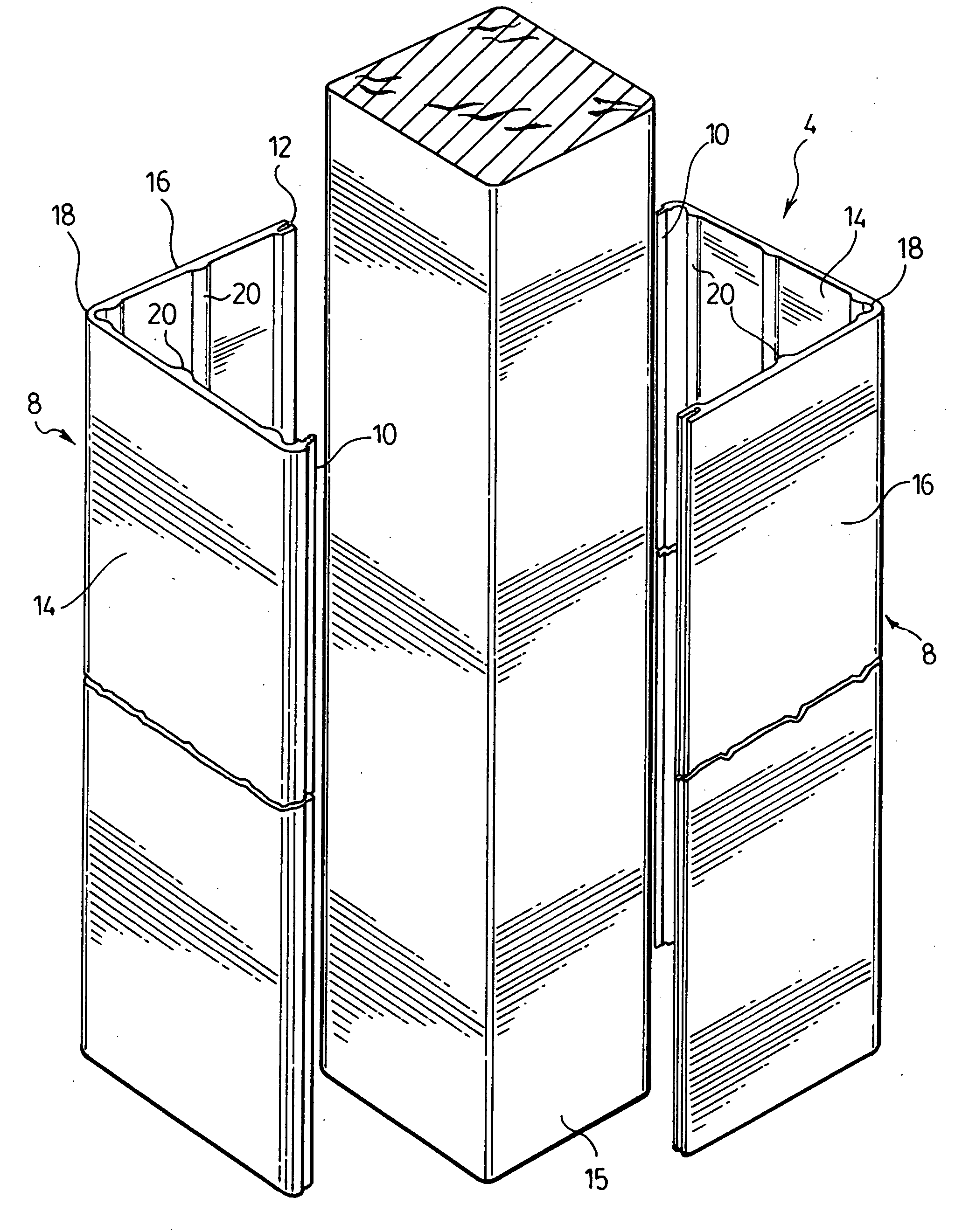

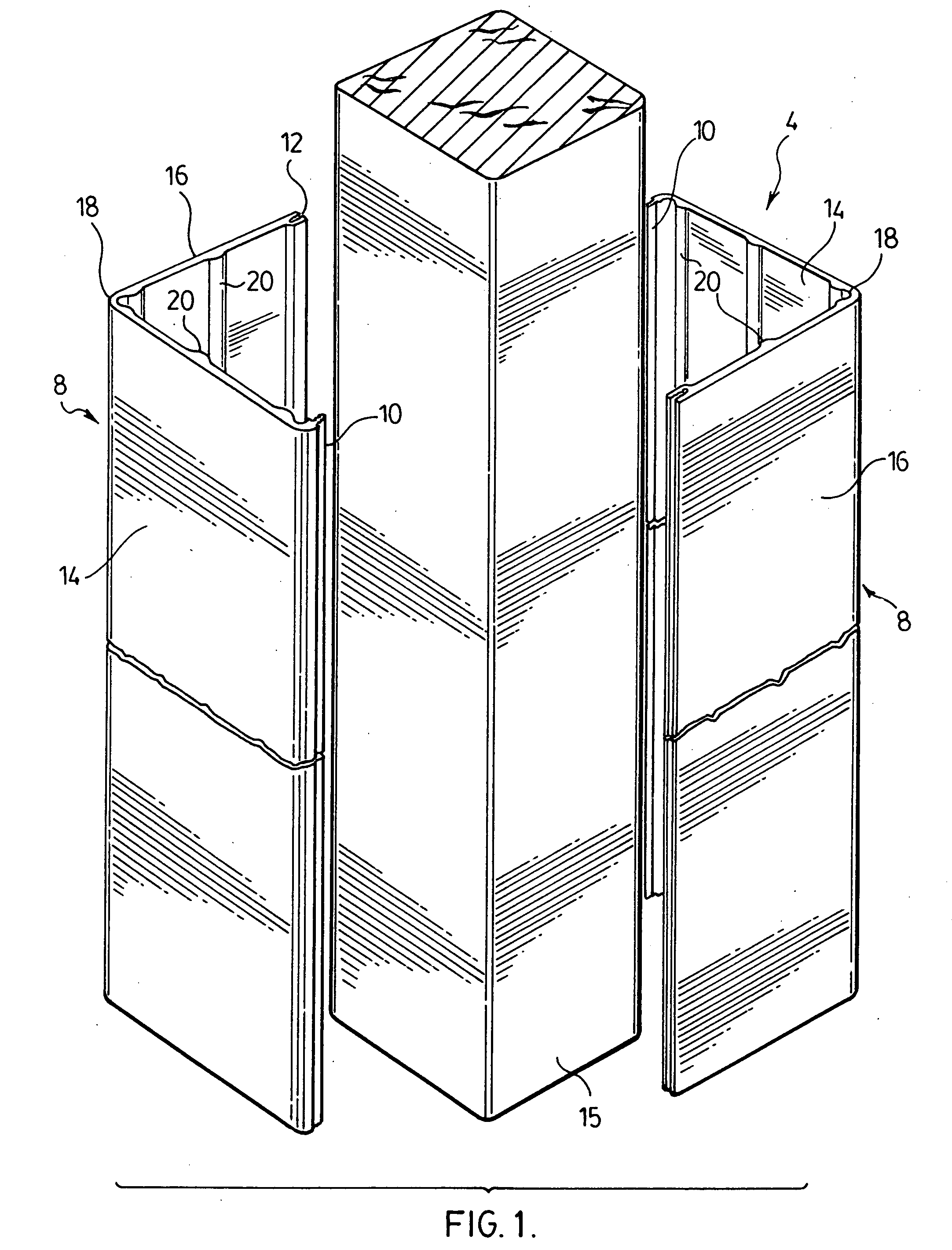

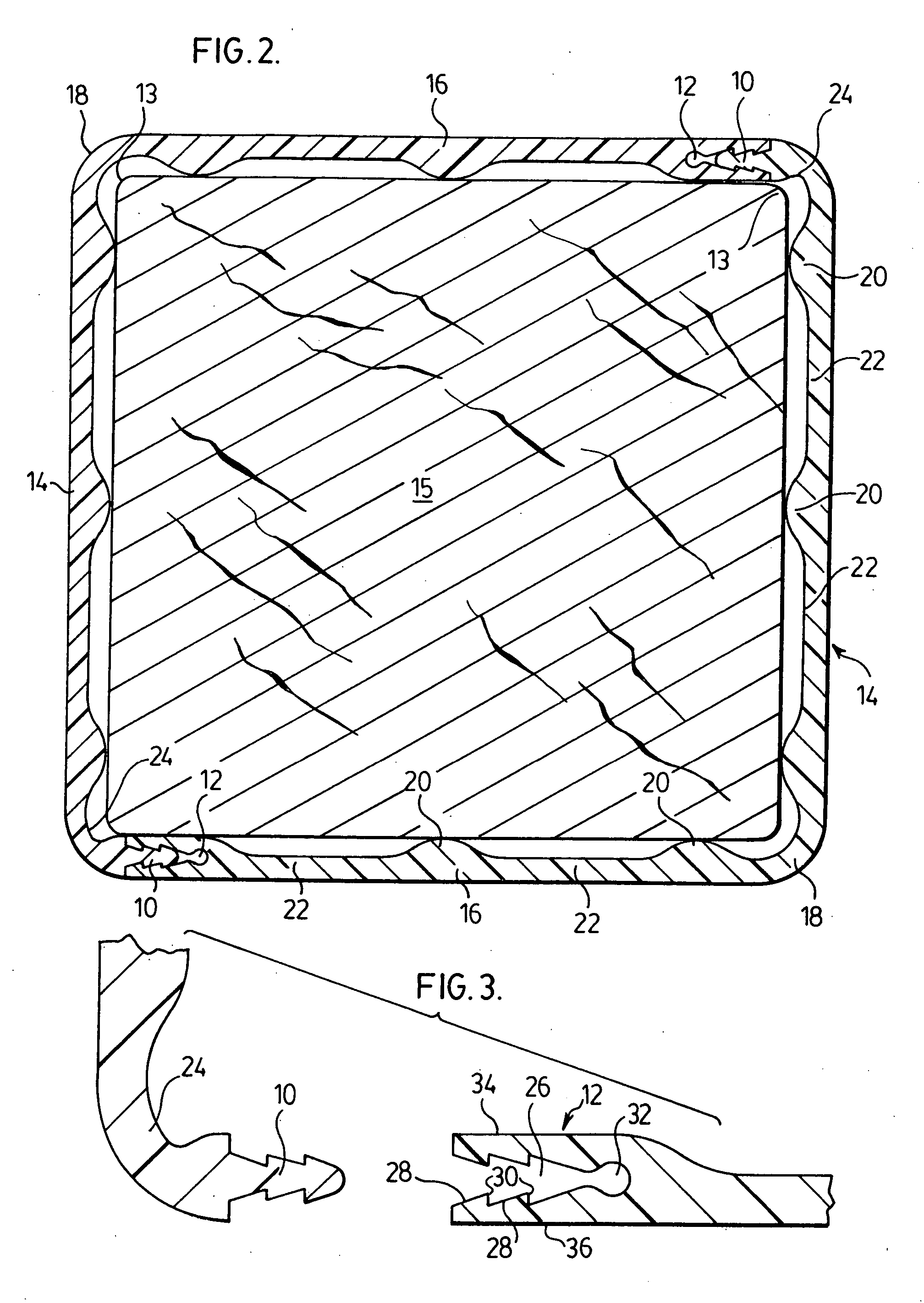

[0025]FIGS. 1, 2, 3 and 4 show the post sleeve system 2 defined by the two-piece post sleeve 4 and the post collars 6. As each of these components are of a split configuration they can be applied about a post once it is secured in place.

[0026] The post sleeve 4 comprises a reversible extruded component 8 which joins to a reversed like component due to a male connector 10 provided at one edge of the component which is received within a narrow elongate female recess 12 provided on the opposite arm. The component includes a first arm 14 and a second arm 16 joined by a curved recess portion 18. Each of the arms 16 and 14 include standoff ribs 20 which are of a thicker section with the stand off ribs joins by thinned portions 22. The second arm 16 is of a slightly reduced width with respect to arm 14 as the male connector includes a small transition segment that extends arm 16 when the male connector is joined with the female connector.

[0027] As shown in FIGS. 2 and 3 the standoff rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com