Underground drilling device employing down-hole radar

a technology of radar and drilling device, applied in the direction of directional drilling, borehole/well accessories, survey, etc., can solve the problems of affecting the original condition of structures or roadways, damage to previously buried utilities, and structures or roadways disturbed by digging trenches. rarely restored to their original condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

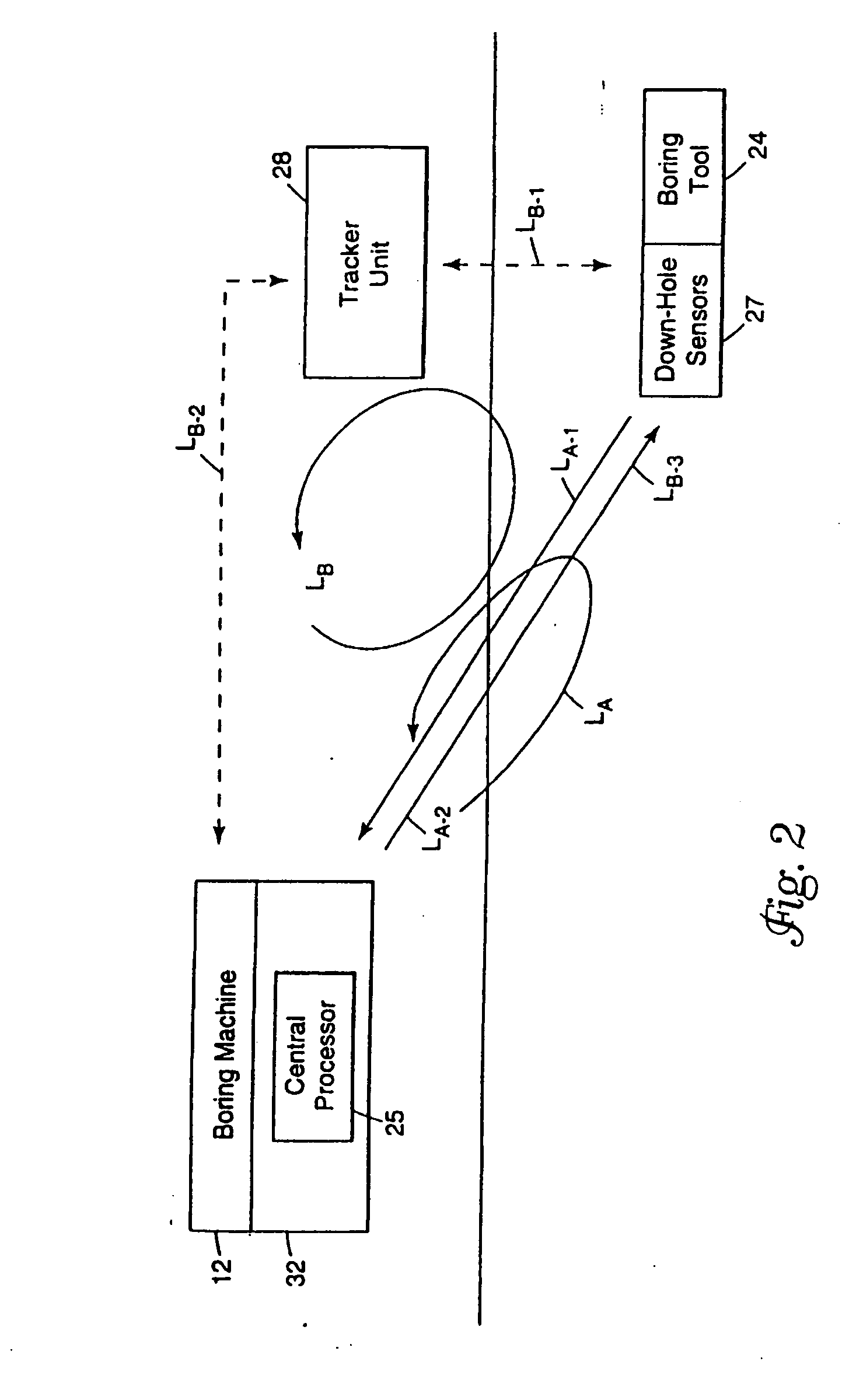

[0066]FIG. 2 illustrates an important aspect of the present invention. In particular, FIG. 2 depicts various embodiments of a closed-loop control system as defined between the boring machine 12 and the boring tool 24. According to one embodiment, communication of information between the boring machine 12 and the boring tool 24 is facilitated via the drill string. A control loop, LA, illustrates the general flow of information through a closed-loop boring control system according to the present invention. The down-hole sensor unit 27 provided in the boring tool 24 provides location and orientation data. The acquired data may be processed locally within the down-hole sensor unit 27. The data acquired at the boring tool 24 is transmitted as an information signal along a first loop segment, LA-1, and is received by the boring machine 12. The received information signal is processed by the central processor 25 typically provided in a control unit 32 of the boring machine 12. Control sign...

second embodiment

[0068] In accordance with a second embodiment, a closed-loop control system is defined between the boring machine 12, boring tool 24, and tracker unit 28. A control loop, LB, illustrates the general flow of information through this embodiment of a closed-loop control system of the present invention. The boring tool 24 transmits an information signal along a first loop segment, LB-1, which is received by the tracker unit 28. In response to the received information signal, the tracker unit 28 transmits an information signal along a second loop segment, LB-2, which is received by the central processor 25. The received information signal is processed by the central processor 25 of the boring machine 12. In response to the processed information signal, desired adjustments are made by the boring machine 12 to alter or maintain the activity of the boring tool 24, such adjustments being effected along a third loop segment, LB-3, of the control loop, LB. It is noted that the first and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com